Abstract

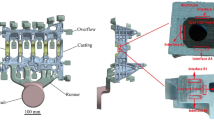

The paper presents the problem of obtaining a permanent diffusion joint between the working surface layer and the base part in a bimetallic casting. The bimetallic castings studied here were obtained as a result of using the founding method of layer coating directly in the cast process, i.e., the so-called method of mould cavity preparation by monolithic insert. The castings prepared using this method consist of two fundamental parts, i.e., the base which constitutes typical foundry material, i.e., grey cast iron and the working surface layer which constitutes plate of chromium–nickel stainless steels, X2CrNi 18-9 and X2CrNiMoN22-5-3 grade. On the basis of the obtained results it was confirmed that the decisive phenomena that are needed to create a permanent joint between the two components of the bimetallic casting are carbon and heat transport in the direction from the high-carbon and hot base material which was poured into the mould in the form of liquid metal to the low-carbon and cold material of the working layer which was placed in the mould cavity in the form of a monolithic insert.

Similar content being viewed by others

References

Žic S, Džambas I, and Konić M, Metalurgija 48 (2009) 51.

Hua W, Adv Mater Res 535-537 (2012) 266.

Xiaofeng X, Shengping Y, Xiaoguang Z, and Qiong X, China Foundry 9 (2012) 136.

Marukovich E, Branovitsky A, Na Y, Lee J, and Choi K, Mater Des 27 (2006) 1016.

Heijkoop T, and Sare I, Cast Met 2 (1989) 160.

Gawroński J, Szajnar J, and Wróbel P, J Mater Process Technol 157–158 (2004) 679.

Szajnar J, Wróbel P, and Wróbel T, Arch Foundry Eng 8 (2008) 105.

Wróbel T, in Proc METAL 2011 20th Anniversary International Conference on Metallurgy and Materials, (eds) Podjuklová J and Štěpánek I, Tanger, Brno (2011), p 758.

Jura S, and Suchoń J, Solidif Met Alloys 24 (1995) 67 (in Polish).

Bartocha D, Suchoń J, and Jura S, Solidif Met Alloys 38 (1998) 151 (in Polish).

Qian M, Harada S, Kuroshima Y, and Nagayoshi H, Mater Sci Eng A A208 (1996) 88.

Arnold B, Heijkoop T, Lloyd P, Rubens G, and Sare I, Wear 203–204 (1997) 663.

Kilarski J, and Suchoń J, Arch Foundry 6 (2006) 266.

Şimşir M, Kumruoğlu L, and Özer A, Mater Des 30 (2009) 264.

Cingi C, Rauta V, Niani E, and Orkas J, Mater Sci Forum 654–656 (2010) 2712.

Xiong B, Cai C, and Lu B, J Alloy Compd 509 (2011) 6700.

Xiong B, Cai C, Wan H, and Lu B, Mater Des 32 (2011) 2978.

Viala J, Peronnet M, Barbeau F, Bosselet F, and Bouix J, Composites A 33 (2002) 1417.

Szymczak T, Arch Foundry Eng 11 (2011) 215.

Lucey T, Wuhrer R, Moran K, Reid M, Huggett P, and Cortie M, J Mater Process Technol 212 (2012) 2349.

Cholewa M, Wróbel T, Tenerowicz S, and Szuter T, Arch Metall Mater 55 (2010) 771.

Wróbel T, Cholewa M, and Tenerowicz S, Arch Foundry Eng 11 (2011) 105.

Wróbel T, J Mater Eng Perform 23 (2014) 1711.

Duda P, and Taler J, Solving Direct and Inverse Heat Conduction Problems, Springer, Berlin (2006), p 363.

Acknowledgments

The financial support from the Polish National Science Centre is kindly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wróbel, T., Wiedermann, J. & Skupień, P. Bimetallic Castings in a Chromium–Nickel Stainless Steel Working Surface Layer Configuration with a Grey Cast Iron Base. Trans Indian Inst Met 68, 571–580 (2015). https://doi.org/10.1007/s12666-014-0488-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-014-0488-2