Abstract

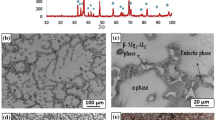

Friction Stir (FS) welding promises joints with low porosity, fine microstructures, and low vaporization of volatile elements compared with conventional welding techniques. FS weld was carried out on Vacuum Induction Melted 5 mm thick cast Aluminum–Magnesium–Scandium (Al–Mg–Sc) alloy plates. Microstructural evaluation revealed that due to FS welding, fine and fragmented dynamically recrystallized grains have been formed in the weld nugget. Tensile fracture occurred out side the weld zone. The tensile strength of the welded joint is more than the cast base metal. The hardness of the FS welded joint is less than the hardness of the cast base metal. The minimum hardness was located on the retreating side of the weld. These results clearly show that FSW process is amenable to join cast Al–Mg–Sc alloy.

Similar content being viewed by others

References

Willey L A, United States Patent 3619181, (1971).

Filatov Yu A, Welding in the world (1994), p 428.

Roder O, Schauerte O, Lutjering G, Gysler A, Mater Sci Forum 217–222 (1996) 1835.

Aiura T, Sugawara N, and Miura Y, Mater Sci Eng A A280 (2000) 139.

Lathabai S, and Lloyd P G, Acta Mater 50 (2002) 4275.

Huang C, and Kou S, Weld J 79 (2000) 113s.

Zhao H, White D R, and Debroy T, Int Mater Rev 44 (1999) 238.

Sutton M A, Reynolds A P, Wang D Q, Hubbard C R, J Eng Mater Technol 124 (2002) 215.

Thomas W M, Nicholas E D, Needam J C, Murch M G, Templesmith P, and Dawes C J, GB Patent application No. 9125978.8 (1991).

Hirata T, Oguri T, Hagino H, Tanaka T, Chung S W, Takigawa Y, Higashi K, Mater Sci Eng A 456 (2007) 344.

Fujii H, Cui L, Maeda M, and Nogi K, Mater Sci Eng A 419 (2006) 25.

Watanabe T, Takayama H, and Yanagisawa A, J Mater Process Technol 178 (2006) 342.

Sato Y S, Hwan S, Park C, and Kokawa H, Metall Mater Trans A 32 (2001) 3033.

Shigematsu I, Kwon Y-J, Suzuki K, Imai T, and Saito N, J Mater Sci Lett 22 (2003) 353.

Svensson L-E, Karlsson L, Larsson H, Karlsson B, Fazzini M, and Karlsson J, Sci Technol Weld Join 5 (2000) 285.

Lombard H, Hattingh D G, Steuwar A, and James M N, Eng Fract Mech 75 (2008) 341.

Peel M, Steuwer A, Preuss M, and Withers P J, Acta Mater 51 (2003) 4791.

Mishra R S, and Ma Z Y, Mater Sci Eng R 50 (2005) 1.

Liu H J, Fujii H, and Nogi K, Mater Sci Technol 20 (2004) 399.

Genevois C, Deschamps A, and Vacher P, Mater Sci Eng A 415 (2006) 162.

Kwon Y J, Shigematsu I, and Saito N, Scripta Mater 49 (2003) 785.

Salem H G, Scripta Mater 49 (2003) 1103.

Attallah M M, Davis C L, and Strangwood M, Sci Technol Weld Join 12 (2007) 361.

Lenczowski B, Hack T, Wieser D, Tempus G, Fischer G, Becker J, Folkers K, Braun R, and Lutjering G, Mater Sci Forum 331–337 (2000) 957.

Cabello Munoz A, Ruckert G, Huneau B, Sauvage X, Marya S, J Mater Pro Technol 197 (2008) 337.

Zhao J, Jiang F, Jian H, Wen K, Jiang L, Chen X, Mater Des 31 (2010) 306.

Karthikeyan L, Senthilkumar V S, Balasubramanian V, and Natarajan S, Mater Des 30 (2009) 2237.

Marzoli L M, Strombeck A V, Dos Santos J F, Gambaro C, and Volpone L M, Composites Sci Technol 66 (2006) 363.

Santella M L, Engstorm T, Storjohann D, and Pan T Y, Scripta Mater 53 (2005) 201.

Ma Z Y, Mishra R S, and Mahoney M W, Scripta Mater 50 (2004) 931.

Ma Z Y, Sharma S R, and Mishra R S, Mater Sci Eng A 433 (2006) 272.

Nakata K, Kim Y G, Fujii H, Tsumura T, and Komzaki T, Mater Sci Eng A 437 (2006) 274.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Subbaiah, K., Geetha, M., Govindaraju, M. et al. Mechanical Properties of Friction Stir Welded Cast Al–Mg–Sc Alloys. Trans Indian Inst Met 65, 155–158 (2012). https://doi.org/10.1007/s12666-011-0117-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-011-0117-2