Abstract

Modified 9Cr-1Mo steel is being used extensively as structural material for steam generator components of liquid metal cooled fast breeder reactor and fossil fired power plants. The selection of this material is primarily based on a good combination of mechanical properties, high thermal conductivity, low thermal expansion coefficient and good resistance to stress corrosion cracking in water-steam and sodium environment systems compared to austenitic stainless steels. A further improvement of the thermal efficiency of modern steam turbines can be achieved by increasing the steam operating temperature. It has been found that the substitution of W for Mo enhances the high temperature tensile strength, fracture toughness and creep strength. This had led to the development of P92 Steel.

The components of the steam generators are often subjected to repeated thermal stresses as a result of temperature gradients that occur on heating and cooling during start-ups and shut-downs or during temperature transients. This leads to low cycle fatigue (LCF) damage in the component. However, the data on LCF properties of the W added 9Cr steel (designated as P92 steel) is scarce and this paper aims in understanding the high temperature low cycle fatigue behaviour of P92 Steel.

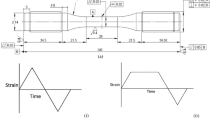

Total axial strain controlled low cycle fatigue tests have been conducted in air in the temperature range 823 and 873 K to ascertain the influence of temperature on the LCF behaviour of the steel. A constant ramp rate of 3 × 10−3 s−1 was employed for all the tests. The alloy exhibited a continuous softening before the final load drop that occurred due to the propagation of macro fatigue cracks. The softening rate is more for the tests conducted at higher strain amplitudes compared to that of lower strain amplitudes. Fatigue life decreased with increasing temperature and strain amplitude. In this paper the observed LCF results have been explained based on the detailed metallography and fractography conducted on the failed samples.

Similar content being viewed by others

References

Ebi G and McEvily A J, Fatigue Fract Engg Mater Struct., 17 (1984) 299.

Swindman R Q, Low Cycle Fatigue, ASTM STP 942, Solomon S D, Halford G R, Kaisand L R and Leis B N, Eds. (1998) ASTM, Philadelphia, 107.

Asada Y, Dozaki K, Ueta M, Ichimiya M, Mori K, Taguchi K, Kitagawa M, Nishida T, Sakon T and Sukekawa M, Nucl Engng Des. 139 (1993) 269.

Jones W B, Ferritic Steels for High Temperature Applications, Proceedings of ASM International Conference on Production, Fabrication, Properties and Application of Ferritic Steels for High Temperature Applications, Warren, PA, October 6–8, 1981, ed. Khare A K, ASM, Metals Park, Ohio, (1983) 221.

Nagesha A, Valsan M, Kannan R, Bhanu Sankara Rao R, Mannan S L, Int. J. Fatigue, 24(12) (2002) 1285.

Eifler D and Rottger D, Proc. 7th Int. Fatigue Congress, Fatigue’ 99, June 1999, Beijing, Xue-Ren Wu and Zhong-Guang Wang, Eds. 4 (1999) 2145.

Nishino S, Shiozawa K, Takahashi K, Seo S and Yamamoto Y, Proc. 7th Int. Fatigue Congress, Fatigue’ 99, June 1999, Beijing, Xue-Ren Wu and Zhong-Guang Wang, Eds. 4 (1999) 2177.

Data sheets on elevated temperature time-dependent low cycle fatigue properties of ASTM A387 Grade 91 (9Cr-1Mo) steel plate for pressure vessels, NRIM (data sheet No. 78).

Gieseke B G, Brinkman C R and Maziasz P J, Microstructure and Mechanical properties of Aging Material, eds. Liaw P K, Viswanathan R, Murty K L, Simonen E P and Frear D, The Minerals, Metals and Materials Society (1993) 197.

Kim S and Weertman J R, Metall Trans A 19 (1988) 999.

Okamura H, Ohtani R, Saito K, Kimura K, Ishii R, Fujiyama K, Hongo S, Iseki T and Uchida H, Nucl Engng Design 193 (1999) 243.

Kannan R, Sandhya R, Ganesan V, Valsan M and Bhanu Sankara Rao K, Journal of Nuclear Materials 384 (2009) 286

Park J S, Kim S J and Lee C S, Mater. Sci. Engng. A 298 (2001) 127.

Yumen L, Mater. Sci. Techno., A113 (1989) 237.

Li D M, Kim K W, Lee C S, Int. J. Fatigue 19 (1997) 607.

Raske D T, and Morrow J M, ASTM STP 464 (1969) 1.

Landgraf R W, Morrow J and Endo T, J Mater JMLSA 4(1) (1969) 176.

Basquin OH, Proc. ASME Soc Test Mater ASTEA 10 (1910) 625.

Coffin Jr L F, Trans ASME 76 (1954) 931.

Manson S S, NASA Tech Note (1954) 2933.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kannan, R., Srinivasan, V.S., Valsan, M. et al. High temperature low cycle fatigue behaviour of P92 tungsten added 9Cr steel. Trans Indian Inst Met 63, 571–574 (2010). https://doi.org/10.1007/s12666-010-0084-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-010-0084-z