Abstract

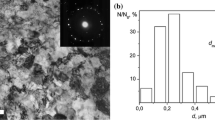

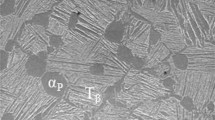

Creep and creep crack growth behaviour of a near α titanium alloy has been investigated at 600°C which is affected by primary α content. The alloy was heat treated at different temperatures so as to obtain different levels of equiaxed primary α in the range from 5 to 24 %. Constant load creep tests were carried out at 600°C in the stress range 250 to 400 MPa till rupture of the specimens. Creep crack growth tests were carried out at 600°C. Creep data reveals with increase in primary α content leads to creep weakening. On similar lines maximum creep crack growth resistance is associated with the alloy with lowest primary α content. Microstructural and fractographic examination has revealed that creep fracture occurs by nucleation, growth and coalescence of microvoids nucleated at primary β / transformed β (matrix) interfaces. On the other hand, creep crack growth occurs by surface cracks nucleated by fracture of primary α particles as well as by growth and coalescence of microvoids nucleated at primary β / transformed β (matrix) interfaces in the interior of the specimen.

Similar content being viewed by others

References

Ohji K, Ogura K and Kubo S, JSME, No. 790-13, (1979) 18 (In Japanese).

Andres C, Gysler A and Lutjering G, Z.Metallkd. 88 (1997) 197.

Mishra H, Ghosal P, Nandy T K and Sagar P K, Mater.Sci.Eng.A 399 (2005) 222.

Satyanarayana D V V, Omprakash C M, Vikas Kumar, In press Metall. Mat. Trans. A, (2008).

Borchert B, Daubler M A, Proceedings of the Sixth World Conference on Titanium, France, (1988) 467.

Lutjering G, Helm D, Daubler M A, Proceedings of the fifth World Conference on Fatigue and Fatigue Thresholds, Canada, (1993) 165.

Cope M T, M.J. Hill, Proceedings of the Sixth World Conference on Titanium, France, (1988) 153.

Kestler H, Mughrabi H and Renner H, Titanium’95 Science and Technology, (1995) 1171.

Neal D F, Titanium Science and Technology, (1985) 2419.

Thiehsen K E, Kassner M E, Pollard J, Hiatt D R, Bristow B M, Metall. Trans. 24A (1993) 1819.

Ankem S and Seagle S R, Titanium Science and Technology, (1985) 2411.

Bania P J and Hall J A, Titanium Science and Technology, (1985) 2371.

Woodfield A P, Wardle A M and Loretto M H, Proceedings of the Sixth World Conference on Titanium, France, (1988) 357.

Cho W, Jones J W, Allison J E and Donion W T, Proceedings of the Sixth World Conference on Titanium, France, (1988) 187–197.

“Standard Test Method for Measurement of Creep Crack Growth Rates in Metals: ASTM standard 1457-92. ASTM Book of Standards, 03.01 (1992) 1031.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Omprakash, C.M., Satyanarayana, D.V.V. & Kumar, V. Effect of microstructure on creep and creep crack growth behaviour of titanium alloy. Trans Indian Inst Met 63, 457–459 (2010). https://doi.org/10.1007/s12666-010-0064-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-010-0064-3