Abstract

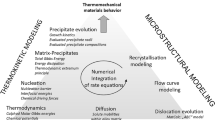

Simulation results of microstructure evolution in technical aluminum alloys are presented. The examples comprise solidification and further heat treatment of three different alloy classes, namely for the hypoeutectic alloy AA6061, the near eutectic alloy A356 and the highly alloyed, hypereutectic commercial alloy KS1295 being used in automotive applications. After a short introduction to the simulation models being applied — especially to the multiphase-field approach coupled to thermodynamic databases — the evolving microstructures are discussed in the context of the interplay between thermodynamics, kinetics, interfacial properties and nucleation.

Similar content being viewed by others

References

Saunders N and Miodownik A, CALPHAD calculation of phase diagrams: a comprehensive guide. Elsevier; 1998.

Thermo-Calc Software: http://www.thermocalc.com

ThermoTech: http://www.sentesoftware.co.uk

Steinbach I, Pezzolla F, Nestler B, Seeßlberg M, Prieler R, Schmitz G J and Rezende J L L, A phase field concept for multiphase systems. Physica D, 94 (1996) 135.

Grafe U, Böttger B, Tiaden J and Fries S G, Coupling of Multicomponent Thermodynamic Databases to a Phase Field Model: Application to Solidification and Solid State Transformations of Superalloys, Scripta Materialia, 42(12) (2000) 1179.

Böttger B, Grafe U, Ma D and Fries S G, Mater. Sci. Technol., 16 (2000) 1425.

Eiken J, Böttger B and Steinbach I, Multiphase-field approach for multicomponent alloys with extrapolation scheme for numerical application, Phys. Rev. E, 73 (2006) 066122.

Böttger B, Apel M, Eiken J, Schaffnit P and Steinbach I, Phasefield simulation of solidification and solid-state transformations in multicomponent steels, Steel Research Int., 79(8) (2008) 608.

Eiken J, Böttger B and Steinbach I, Simulation of Microstructure Evolution during solidification of Magnesium-Based Alloys, Trans. Indian Inst. Met., 60(2–3) (2007) 179.

Böttger B, Eiken J, Ohno M, Klaus G, Fehlbier M, Schmid-Fetzer R, Steinbach I and Bührig-Polaczek A, Controlling microstructure in magnesium alloys: a combined thermodynamic, experimental and simulation approach. Adv. Eng. Mater., 8 (2006) 241.

Warnken N, Ma D, Mathes M and Steinbach I, Investigation of eutectic island formation in SX superalloys, Materials Science and Engineering A, 413(12) (2005) 267.

MICRESS www.micress.de

Steinbach I, Böttger B, Eiken J, Warnken N and Fries S G, CALPHAD and Phase-Field Modeling: A Successful Liaison, Journal of Phase Equilibria and Diffusion, 28(1) (2007) 101

Kitashima T, Coupling of the phase-field and CALPHAD methods for predicting multicomponent solid-state phase transformations, Phil. Mag.. 88(11) (2008) 1615.

Fries S G, Böttger B, Eiken J and Steinbach I, Upgrading CALPHAD to microstructure simulation: the phase-field method, Int. J. Mat. Res., 100 (2009) 2

Qin R S, Wallach E R and Thomson R C, A phase-field model for the solidification of multicomponent and multiphase alloys, J. Cryst. Growth, 279(1–2) (2005) 163

Kovacevic I, Simulation of spheroidisation of elongated Si-particle in Al-Si alloys by the phase-field model, Mater. Sci. Eng. A, 496(1–2) (2008) 345

Wang J S and Lee P D, Quantitative Simulation of Fe-rich Intermetallics in Al-Si-Cu-Fe Alloys during Solidification, Proceedings of 138th TMS Annual Meeting and Exhibition, San Francisco Feb 2009, VOL 1: Materials Processing and properties

Böttger B, Eiken J and Steinbach I, Phase field simulation of equiaxed solidification in technical alloys, Acta Mater., 54 (2006) 2697.

Böttger B, Apel M, Barnes S, Scheppe F and Sagel A, Computer Aided Development of Improved Alloys for Automotive Pistons, presentation at the 11th International Conference on Aluminium Alloys ICAA Neckarsulm (Germany), (2008)

Qin R S, Wallach E R, A phase-field model coupled with a thermodynamic database, Acta Mat. 51(20) (2003) 6199

COST 507 Thermochemical database for light metal alloys, Vol.2, Eds. I. Ansara, A.T. Dinsdale, M.H. Rand, Publications of the European Communities, Luxembourg, 1998 (ISBN 92-828-3902-8). Database available e.g. from [3]

MOBAL1: Mobility database for Al-alloys, Thermo-Calc Software: www.thermocalc.se

Sha G K A, O’Reilly Q, Cantor B, Worth J and Hamerton R, Growth Related metastable phase selection in A 6XXX series wrought Al alloy, Mat. Sci. Eng. A, 304–306 (2001) 612.

Samaras S N, Modelling of microstructure evolution during precipitation processes: a population balance approach of the KWN model, Modelling and Simulation in Materials Science and Engineering, 14(8) (2006) 1271

Tanihata H, Sugawara T, Matsuda K and Ikeno S, Journal of Materials Science, 34 (1999) 2105.

Kurz-Fisher, Fundamentals of Solidification; Trans Tech Publications (1989)ISBN 0-87849-522-3

Carré A, et al., to be published

TTAl5: thermodynamic database for Aluminum alloys developed by [4]

Böttger B, Eiken J and Apel M, Phase-field simulation of microstructure formation in technical castings — A self-consistent homoenthalpic approach to the micro-macro problem, J. Comput. Phys. (2009) 6784

Böttger B, et al., to be published

Apel M, Benke S and Steinbach I, Virtual Dilatometer Curves and effective Young’s modulus of a 3D multiphase structure calculated by the phase-field method, Computational Materials Science, 45 (2009) 589

G.J. Schmitz and U. Prahl: Toward a Virtual Platform for Materials Processing, JOM, 61(5) (2009)19

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Böttger, B., Carré, A., Eiken, J. et al. Simulation of microstructure formation in technical aluminum alloys using the multiphase-field method. Trans Indian Inst Met 62, 299–304 (2009). https://doi.org/10.1007/s12666-009-0046-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-009-0046-5