Abstract

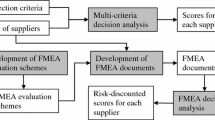

Risks play an important role in supply chain vulnerability, performance maintenance, and competitive advantage. Through adopting strategies by the exclusive supplier, the potential risks in the supply chain become actual. The risk interdependencies are not involved in the effectiveness of selecting the appropriate strategy. Since a risk may be influenced by another risk in a desirable or undesirable way, estimation of the real risk value is necessary. In this paper, first, the real weight of the actual risks for each strategy is specified through a new approach. Then, considering risk interdependency effects, the amount of increase or decrease in a risk value is determined by proposing an improved DEMATEL method. The real value of each risk is a combination of factors such as real weight, actual value, and sensitivity to other risk effects. Finally, the value of objective functions for each strategy is determined and all strategies will be re-ranked by the proposed approach (three-dimensional integrated mean method). However, the proposed method is used for ranking of Exclusive Supplier Strategies or decision in this paper, but it can be used for many decision-making procedures.

Similar content being viewed by others

Notes

Decision Making Trial and Evaluation.

Technique for Order Preference by Similarity to Ideal Solution.

Elimination et Choice Translating Reality.

Linear programming for Multidimensional Analysis of Preference.

References

Abarghoei NS, Hosaini-Nasab H, Fakhrzad MB (2012) Design of the evaluation model for total ergonomics interventions with fuzzy approach. Sci J Pure Appl Sci 1(3):119–129

Bogataj D, Aver B, Bogataj M (2016) Supply chain risk at simultaneous robust perturbations. Int J Prod Econ 181:68–78

Boran FE, Genc S, Kurt M, Akay D (2009) A multi-criteria intuitionistic fuzzy group decision making for supplier selection with TOPSIS method. Expert Syst Appl 36(8):11363–11368

Büyüközkan G, Göcer F (2017) Application of a new combined intuitionistic fuzzy MCDM approach based on axiomatic design methodology for the supplier selection problem. Appl Soft Comput 52:1222–1238

Chen K, Xiao T (2015) Outsourcing strategy and production disruption of supply chain with demand and capacity allocation uncertainties. Int J Prod Econ 170:243–257

Comes T, Hiete M, Wijngaards N, Schultmann F (2011) Decision maps: a framework for multi-criteria decision support under severe uncertainty. Decis Supp Syst 52(1):108–118

Dong Q, Cooper O (2016) An orders of magnitude AHP supply chain risk assessment framework. Int J Prod Econ 182:144–156

Ebrahimy Zade A, Fakhrzad MB (2013) A dynamic genetic algorithm for solving a single machine scheduling problem with periodic maintenance. ISRN Indu Eng 21:211–220

Felfel H, Ayadi O, Masmoudi F (2016) Multi-objective stochastic multi-site supply chain planning under demand uncertainty considering downside risk. Comput Ind Eng 102:268–279

Fontela E, Gabus A (1976) The DEMATEL observer. DEMATEL 1976 report. Battelle Geneva Research Center, Geneva, Switzerland

Gabus A, Fontela E (1973) Perceptions of the world problematique: communication procedure. Communicating with those bearing collective responsibility. DEMATEL report no 1. Battelle Geneva Research Centre, Geneva, Switzerland

Ge H, Nolan J, Gray R, Goetz S, Han Y (2016) Supply chain complexity and risk mitigation—a hybrid optimization–simulation model. Int J Prod Econ 179:228–238

Giannakis M, Papadopoulos T (2016) Supply chain sustainability: a risk management approach. Int J Prod Econ 171:455–470

Govindan K, Fattahi M (2017) Investigating risk and robustness measures for supply chain network design under demand uncertainty—a case study of glass supply chain. Int J Prod Econ 183:680–699

Hoffman H, Busse C, Bode C, Henke M (2014) Sustainability-related supply chain risks: conceptualization and management. Bus Strategy Environ 23(3):160–172

Kashi K (2015) The 9th International days of statistics and economics, Prague. September 10–12

Kırılmaz O, Erol S (2017) A proactive approach to supply chain risk management shifting orders among suppliers to mitigate the supply side risks. J Purch Supply Manage 23:54–65

Klibi W, Martel A (2012) Scenario-based supply chain network risk modeling. Eur J Oper Res 223:644–658

Mangla SK, Kumar P, Barua MK (2015) Risk analysis in green supply chain using fuzzy AHP approach—a case study. Resour Conserv Recycl 104:375–390

Merz M, Hiete M, Comes T, Schultmann F (2013) A composite indicator model to assess natural disaster risks in industry on a spatial level. J Risk Res 16(9):1077–1099

Mishra D, Sharma RRK, Kumar S, Dubey R (2016) Bridging and buffering -Strategies for mitigating supply risk and improving supply chain performance. Int J Prod Econ 180:183–197

Mufazzal S, Muzakkir SM (2018) A new multi-criterion decision making (MCDM) method based on proximity indexed value for minimizing rank reversals. Comput Ind Eng 119:427–438

Mulliner E, Malys N, Maliene V (2016) Comparative analysis of MCDM methods for the assessment of sustainable housing affordability. Omega 59:146–156

Nooraie SV, Mellat Parast M (2015) A multi-objective approach to supply chain risk management- Integrating visibility with supply and demand risk. Int J Prod Econ 161:192–200

Qazi A, Quigley J, Dickson A, Ekici SO (2017) Exploring dependency based probabilistic supply chain risk measures for prioritising interdependent risks and strategies. Eur J Oper Res 259:189–204

Schmitt AJ, Singh M (2012) A quantitative analysis of disruption risk in a multiechelon supply chain. Int J Prod Econ 139(1):22–32

Senthil S, Murugananthan K, Ramesh A (2018) Analysis and prioritization of risks in a reverse logistics network using hybrid multi-criteria decision making methods. J Clea Prod 179:716–730

Sherwin MD, Medal H, Lapp SA (2016) Proactive cost-effective identification and mitigation of supply delay risks in a low volume high value supply chain using fault-tree analysis. Int J Prod Econ 175:153–163

Shoushtary MA, Hoseini Nasab H, Fakhrzad MB (2014) Team robot motion planning in dynamics environments using a new hybrid algorithm (honey bee mating optimization-tabu list). Chin J Eng 121:1–8

Venkatesh VG, Rathi S, Patwa S (2015) Analysis on supply chain risks in Indian apparel retail chains and proposal of risk prioritization model using Interpretive structural modeling. J Retail Consum Serv 26:153–167

Vilkoa J, Ritala P, Hallikasa J (2016) Risk management abilities in multimodal maritime supply chains-visibility and control perspectives. Accid Anal Prev 123:469–481

Wagner SM, Neshat N (2010) Assessing the vulnerability of supply chains using graph theory. Int J Prod Econ 126:121–129

Xiao T, Xu T (2014) Pricing and product line strategy in a supply chain with risk-averse players. Int J Prod Econ 156:305–315

Yajing T, Xiaoyu J, Sen Y (2019) New models of supply chain network design by different decision criteria under hybrid uncertainties. J Ambient Intell Hum Comput 10:2843–2853

You-Shyang C, Huan-Ming C, Arun Kumar S, Chien-Ku L, Wen-Bin H (2019) A study for project risk management using an advanced MCDM-based DEMATEL-ANP approach. J Ambient Intell Hum Comput 10:2669–2681

Yu M, Goh M (2014) A multi-objective approach to supply chain visibility and risk. Eur J Oper Res 233(1):125–130

Yuzhen H, Yong D (2018) A hybrid intelligent model for assessment of critical success factors in high-risk emergency system. J Ambient Intell Hum Comput 9:1933–1953

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Calculation of the weight of risks for first priority strategy in the exclusive supplier

-

1.

Comparative matrices for 10 expert opinions about the level of risks with the exclusive supplier:

The opinions of 10 experts are integrated into the geometric mean, as 5.52 is calculated for instance in this way:

In the following, the relative weight of the risks with the exclusive supplier in the integration matrix is specified by normalization method:

-

2.

Risk weights at the level of risks with manufacturers:

-

3.

Risk weights at the level of risks with distributor:

-

4.

Weight at the level of supply chain members with capacity:

-

5.

Weight at the level of supply chain members with price:

-

6.

Multiplication of the matrices of relative weights and determination of the final weight of risks:

As a sample:

Appendix B: Calculating the sensitivity to risk effects for first priority strategy of the exclusive supplier:

-

1.

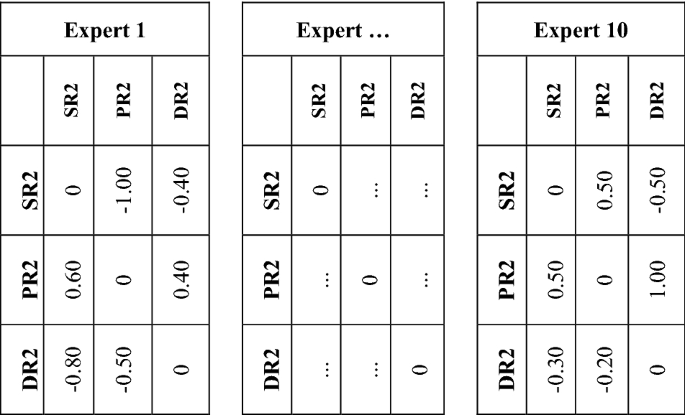

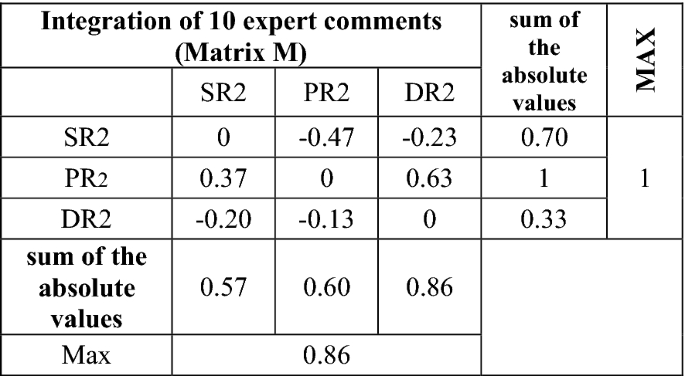

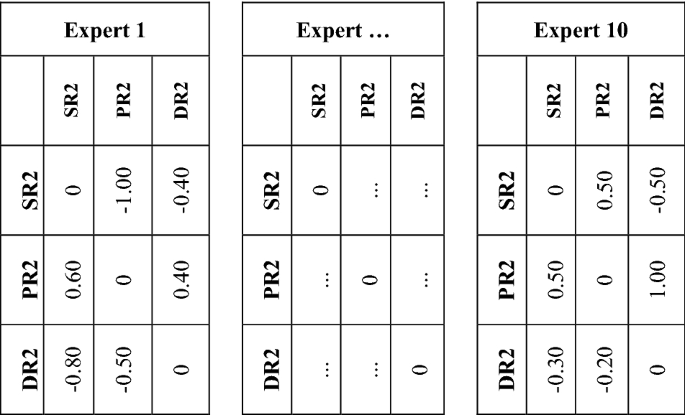

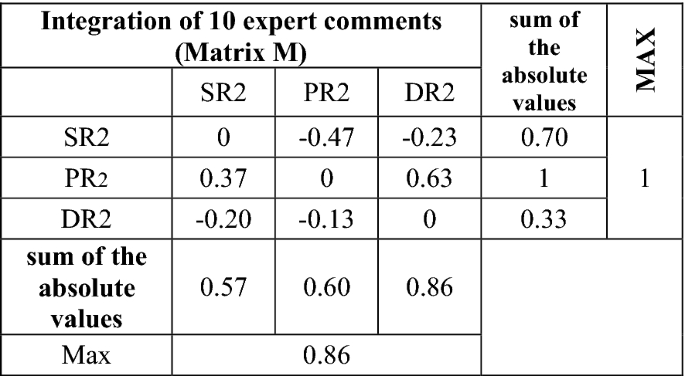

Comparative matrices of 10 expert opinions on the risk interdependencies with the improved DEMATEL method:

$$\alpha = {\text{Min }}\left[ {\frac{ 1}{1} , \frac{ 1}{0. 8 6}} \right]{ = 1 }$$

$$\alpha = {\text{Min }}\left[ {\frac{ 1}{1} , \frac{ 1}{0. 8 6}} \right]{ = 1 }$$ -

2.

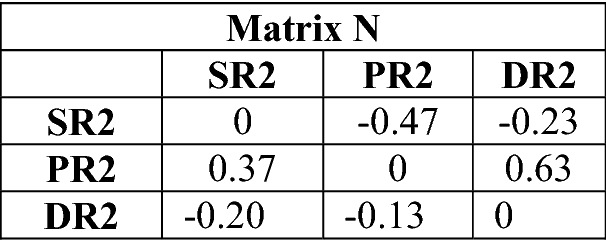

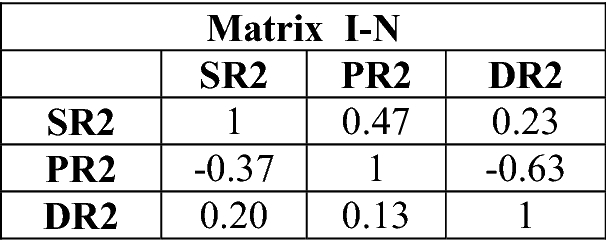

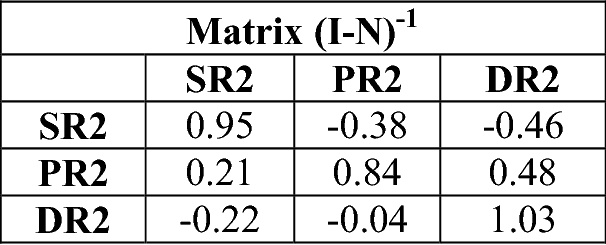

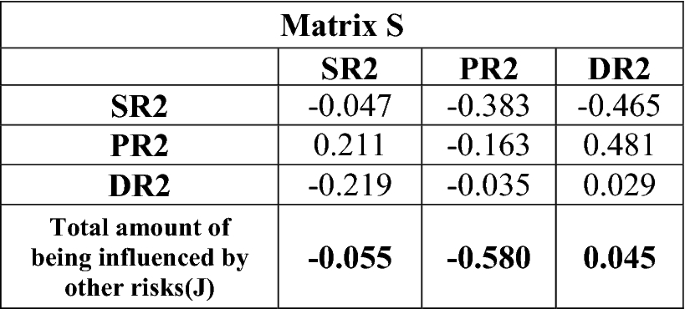

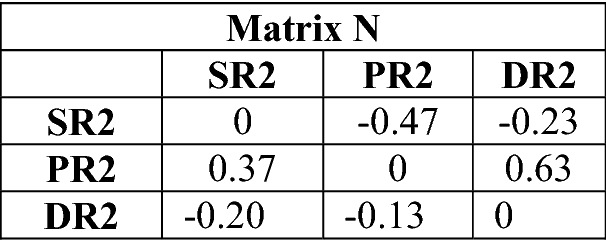

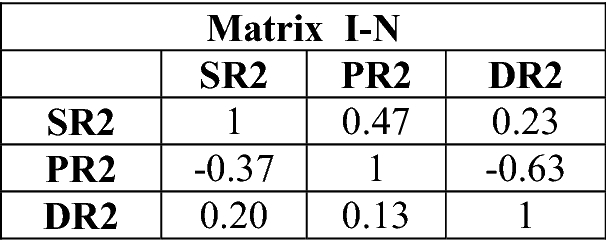

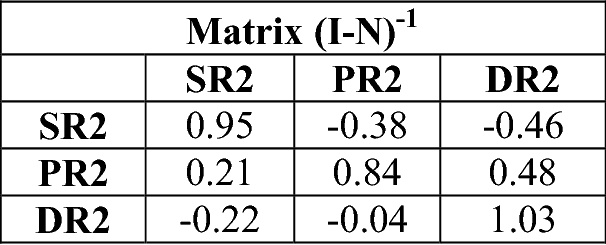

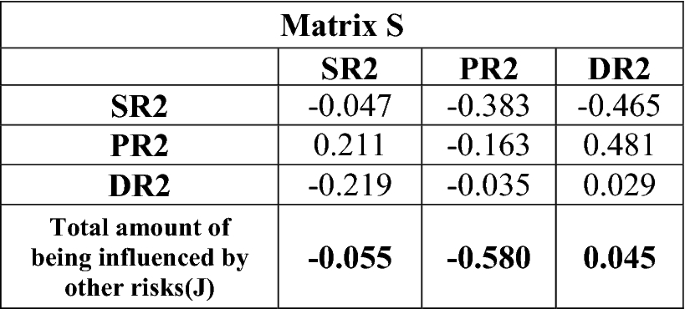

Matrix N, matrix I–N, matrix \(\left( {{\text{I}} - {\text{N}}} \right)^{ - 1}\) and matrix of total relationships (S):

\({\text{N}} = \alpha \times {\text{M}}\) and \(S = N \times \left( {I - N} \right)^{ - 1}\)

Rights and permissions

About this article

Cite this article

Fakhrzad, M.B., Firoozpour, M.R., Hosseininasab, H. et al. Realistic ranking of exclusive supplier strategies based on the evaluation of real value of the risks in the supply chain. J Ambient Intell Human Comput 11, 4695–4712 (2020). https://doi.org/10.1007/s12652-020-01725-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12652-020-01725-5