Abstract

This paper aims to explore an alternative pathway to valorize the organic fraction of municipal solid waste. It is based on the use of enzymatic hydrolysis to obtain a sugar-rich fraction with the potential for liquid fermentative processes and a partially hydrolyzed solid that is evaluated as a substrate for solid-state fermentation. Different strategies to modify the pH of the solid substrate to reach a neutral pH, suitable for the growth of biopesticide producer Bacillus thuringiensis, have been explored. The use of alkaline cosubstrates was evaluated on two different scales and temperature was assessed as a preliminary indicator of the scale-up viability of the process strategy. By ensuring a proper pH throughout the process, the growth and sporulation of Bacillus thuringiensis were achieved. The best cosubstrates and mixing ratios were 50% of digested sewage sludge and 25% of digested organic fraction of municipal solid waste, which led to a spore concentration of 1.1 × 109 spores g−1 of dry matter and 6.4 × 108 spores g−1 of dry matter, respectively. Overall, a reproducible and flexible solid-state fermentation process has been achieved for hydrolyzed organic municipal waste based on the use of alkaline urban wastes as cosubstrates. This valorization pathway fits with the concept of urban biorefineries.

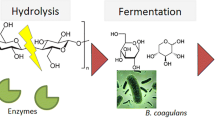

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

The present research provides a novel, flexible and reproducible solid-state fermentation process for the valorization of solid hydrolysates from the organic fraction of municipal solid waste into biopesticides in the context of an urban waste biorefinery. The results obtained will aid in the search and implementation of alternative valorization pathways for specific byproducts of urban waste with large environmental impacts associated.

Introduction

With the increasing municipal solid waste (MSW) generation over the years, significant political and social efforts have been made to introduce selective collection systems that allow for its recycling. In the case of the organic fraction (OFMSW), which represents nearly half of the total MSW [1], selective collection systems prevent its natural biodegradation associated with the release of greenhouse gases and other major environmental impacts [2]. Besides, it improves the quality of OFMSW and facilitates its recycling, which is commonly performed through composting or anaerobic digestion (AD) [3, 4]. Considering the complex composition of the OFMSW, rich in polysaccharides, lignocellulose, proteins, lipids and macro/micronutrients [5], this waste fraction could be exploited to a larger extent for the production of higher-value bioproducts in a biorefinery-like scenario [6]. Besides contributing to the urgent need for ensuring materials and energy supply [7], such a scenario would also justify the significant economic investment required to build a robust and efficient source-separated collection system [3, 6]. In this urban biorefinery context, the widely implemented technology of AD for biogas production can still be used as a complementary technology to handle intermediates [8]. Also, due to its robustness, it can be considered a tool to reduce the risk derived from the heterogeneity and variability of the OFMSW as a substrate.

Enzymatic hydrolysis has emerged as a powerful technology during the development of lignocellulosic biorefineries to break down macromolecules into their functional units [9]. So, its application to municipal waste streams has also been gaining interest [10,11,12,13]. The main components of the OFMSW are carbohydrates and fibers, representing up to 85% of its composition [5], hence their fractioning can generate a variety of fermentable sugars [14]. From a biorefinery perspective, these sugars act as building blocks for different fermentative processes, especially when collected in a liquid fraction [15]. Several papers have explored the use of sugars obtained from the OFMSW in submerged fermentation, for instance, the production of acetic acid [16], succinic acid [17], bacterial poly(3-hydroxybutyrate) [18], and biofuels [19]. The remaining partially hydrolyzed and non-hydrolyzed fibers could also be used in fermentation processes, even though the literature on the topic is scarce.

Solid-state fermentation (SSF) is described as the aerobic fermentation process that takes place in near absence of free water [20]. It has been gaining research interest as it can use different solid organic wastes as substrate and does not always demand strict sterile conditions [21,22,23,24]. For instance, it has been used to produce fungal and bacterial biopesticides [25, 26], aroma compounds [27], bioplastics [28], and biosurfactants [29, 30]. When working with urban organic wastes, complete sterilization is an arduous and energy-intensive task. Therefore, robust microorganisms that can thrive in non-sterile environments would facilitate process implementation in real scenarios. In this sense, Bacillus thuringiensis (Bt) species have been grown successfully under not completely sterile conditions in soy residues [31], OFMSW [24], digestate [22], and wastewater [32]. Biopesticides derived from Bt constitute almost 90% of the world’s biopesticide market [33], a market growing annually at a rate of 15% [34]. These microorganisms are Gram-positive soil bacteria that produce endotoxin proteins accumulated in parasporal crystals during the sporulation phase, which are selectively toxic for pest insects mainly belonging to the orders Lepidoptera, Diptera and Coleoptera [35]. Specifically, Bacillus thuringiensis var. israelensis (Bti) has been described as the most environmentally friendly agent for the control of larval mosquitoes [35] Conventionally, Bt has been produced in liquid media through submerged fermentations but its sporulation process can benefit from solid cultivation [33]. Also, SSF opens up doors for more simple solid formulation possibilities. Like many bacteria, Bt thrives at a pH near neutrality [36, 37]. However, pH control and monitorization during the course of SSF processes are difficult due to the heterogeneity of the solid matrix, a limited amount of free water and a lack of suitable online pH measurement methods. Also, the solid substrate itself might have a buffering effect due to its complex chemical composition [12]. Another major challenge of this technology is the heat and mass transfer-related issues that arise during the scale-up. Therefore, monitoring process temperature from early implementation stages is important to prevent heavy efficiency losses at larger scales [38, 39]. Also, an adequate temperature of around 30 °C must be ensured during the growing phase of Bt [36].

In this paper, the use of the solid hydrolysate from enzymatic hydrolysis of OFMSW is evaluated as a substrate for Bt growth via SSF. Two operational strategies have been tested to adjust pH near neutrality and maximize Bt growth and sporulation at 0.5 L: chemical pH modification and the use of cosubstrates with high buffering capacity. Specifically, byproducts of the AD process of urban wastes have been selected as cosubstrates. Process development to a 1.5 L reactor without temperature control and using non-sterile substrates has also been done to study its suitability for full-scale implementation in a biorefinery-like environment for OFMSW.

Materials and Methods

OFMSW Collection and Hydrolysate Production

The substrate of the enzymatic hydrolysis was the OFMSW collected from a door-to-door collection system selected due to its high quality. It was collected upon arrival at the MSW treatment plant of Mancomunitat La Plana (Malla, Barcelona). The few inert materials (< 1% w w−1), such as plastic, metals, glass or textiles, were removed manually as well as hard shells, bones, hair and excess paper. Then, the OFMSW was shredded mechanically using a home composting shredder (Tecoinsaen SL, Spain) and stored at − 20 °C for a maximum period of three months. Before use, samples were defrosted overnight at 5 °C and sterilized by autoclaving at 121 °C for 30 min. Two different batches of OFMSW (October 2021 and January 2022) were used in this study and their initial characterization can be seen in Table 1.

Enzymatic hydrolysis of homogenized OFMSW was performed using a tailor-made enzymatic cocktail kindly provided by ASA Spezialenzyme GmbH (Wolfenbüttel, Germany) and composed mainly by a blend of cellulases and pectinases but also hemicellulase, ß-glucosidase and α-amylase. Experiments were conducted under sterile conditions in 2 L Erlenmeyer flasks following the provider’s recommendations at 50 °C and initial pH of 4.5, modified using 0.05 M sodium citrate buffer, and 0.05 mL of enzymatic cocktail per g of initial dry matter (DM). The initial solid-to-liquid ratio was set to 10% (w v−1). Erlenmeyer flasks were incubated for 24 h at 180 rpm and rapidly centrifuged at 6000 rpm for 15 min at 4 °C. Then, both fractions were separated and the solid fraction was collected and stored at 5 °C until its use in the SSF for a maximum time of 48 h. Characterization of the final hydrolysate can be seen in Table 2.

Solid-State Fermentation

Microorganism and Inoculum Preparation

All tests were carried out using Bacillus thuringiensis var israelensis (Bti) strain CECT 5904 obtained from Colección Española de Cultivos Tipo (CECT, Valencia, Spain) and preserved at − 80 °C using a seed lot system in cryo-pearls (DeltaLab, Barcelona, Spain). For inoculum preparation, one cryo-pearl was inoculated in 100 mL of sterile Nutrient Broth nº2 (Oxoid CM0067B, England) and incubated at 30 °C and 130 rpm for 20 h when an optical density of 2.5–3.0 was reached. The culture was centrifuged for 10 min at 3500 rpm and 4 °C. First, the obtained pellet was resuspended in 3 mL of the exhausted media and then, diluted 1:10 (v v.1) also with supernatant to reach approximately a concentration of 108 CFU mL−1. No spores were detected at this point.

Chemical pH Modification of the Solid Hydrolysate

Chemical pH modification was done using calcium carbonate (CaCO3). First, the required amount to reach a pH of 7 was determined by adding increasing amounts (1–12 mL) of a 1 M solution to the solid hydrolysate and thoroughly mixing it manually. A 10% of MC increase was set as the maximum modification possible. The solid was left for 1 h at a cold temperature (5 °C) to settle and then pH was measured according to standard procedures.

Cosubstrates and Mixtures Preparation

Three different organic materials related to urban wastes were evaluated as cosubstrates for the SSF process: (i) digested and dewatered sewage sludge coming from the AD process of a municipal wastewater treatment plant (Sabadell, Spain), (ii) digestate from the AD process of a source selected OFMSW treatment plant (Consorci per a la Gestió dels Residus del Vallès Oriental, Granollers, Spain), and (iii) compost from a composting plant of source selected OFMSW (Planta de compostatge de Sant Cugat, Barcelona, Spain). Materials were characterized in terms of dry matter, organic matter (OM), pH, conductivity and biodegradability upon arrival, as detailed later, and stored frozen until use for a maximum period of 3 months. Once defrosted overnight at 5 °C, both digestate and digested sewage sludge were subjected to a hygienization pretreatment (1 h at 70 °C) before their use in SSF processes to pasteurize them as specified in the European Regulation Nº 142/2011.

These materials were mixed individually with the solid hydrolysate at two different weight ratios, 25 and 50%, to prepare the final mixtures used in the SSF processes. The same amount of sterile wood chips of particle size between 0.5 and 5 cm (Acalora, Palets Pla d’Urgell, Spain) was added to the mixtures as a bulking agent to provide porosity to the solid matrices.

Experimental SSF Set-Up

SSF experiments were performed at cylindrical polyvinyl chloride packed-bed reactors of two different scales, 0.5 and 1.5 L. Reactors were completely sealed and equipped with an air inlet and outlet port on the bottom and the top respectively. A humidified airflow was provided through a mass flow meter (Mass-Stream D-6311, Bronkhorst, NL) set to constant aeration of 37 mL g−1 DM h−1 for ensuring aerobic conditions [40]. The oxygen concentration of the exhausted gases was measured after a water trap by an O2–A2 oxygen sensor (Alphasense, UK) connected to a custom-built data acquisition system (Arduino® based). The main difference between both scales was that, at 0.5 L, the temperature was controlled and kept constant at 30 °C by placing the reactor in a water bath, whereas at 1.5 L temperature was not controlled but only monitored using button temperature sensors (Maxim Integrated, U.S.) to obtain accurate temperature profiles at different reactor heights (10 and 20 cm).

Initial experiments were performed at 0.5 L evaluating both the effect of the chemical modification of pH and the use of cosubstrates on Bti growth and sporulation. Experiments were performed in duplicate for each condition. The total amount of the final mixture was kept constant for all the conditions and was 90 g of the substrate and 20 g of the bulking agent, corresponding to a ratio of 1:2 v v−1. The different amounts of cosubstrates used for preparing the mixture were calculated based on wet weight (25 and 50%). Materials were mixed manually and inoculated with 3 mL of diluted Bti to reach approximately 107 CFUs g−1 DM.

Then, the best-performing scenarios were validated in triplicate at 1.5 L and the effect of the mixtures on the temperature was assessed as a preliminary step for scaling up. In this case, 360 g of substrate mixture and 80 g of the bulking agent were mixed and inoculated with 14 mL of diluted Bti inoculum.

Monitoring Parameters

All experiments lasted 72 h, which has been established previously as the maximum spore counting time for Bt [21] and were evaluated in terms of viable cells and spores production. First, a solid-liquid extraction was performed using Ringer solution in a 1:10 (w v−1) ratio at 150 rpm for 20 min. Then, the extract was appropriately diluted and 50 µL plated in triplicate onto Petri dishes containing a Nutrient agar medium (Oxoid CM0003B, England). To measure spores, 20 mL of the previous extract were submitted to a thermal shock by incubating them at 80 °C for 10 min and then placing them into ice before plating [22]. All plates were incubated at 30 °C for 20 h and viable cells or spores were estimated in terms of colony-forming units (CFUs) and related to the DM of the sample, following the equation:

where, nº CFUs is the average of counted CFUs in the Petri dishes, D is the dilution factor of the extract, Ex is the extraction factor (9 mL per g of wet solid), 0.05 is the mL plated and DM is the sample dry matter per g of wet solid.

The sporulation ratio at a certain time is calculated considering that the viable cell count includes both vegetative cells and spores according to the following equation:

The sporulation yield that expresses the concentration of spores produced per initial viable cell inoculated is calculated using the final spores concentration and the initial cell concentration.

With the measured oxygen concentration at the outlet port of the reactor, the specific oxygen uptake rate (sOUR) was calculated as an indicator of the biological activity according to the following equation [41]:

where, sOUR is the specific oxygen uptake rate (g O2 kg−1 DM h−1); F, airflow rate into the reactor (ml min−1); yO2, oxygen molar fraction in the exhaust air (mol O2 mol−1); P, pressure of the system assumed constant at 101,325 (Pa); 32.6, oxygen molecular weight (g O2 mol−1 O2); 60, the conversion factor from minute to hour; 1000a, conversion from ml to L; R, ideal gas constant (8310 Pa L K−1 mol−1); T, the temperature at which F is measured (K); DM, dry matter of solids in the reactor (g); 1000b, conversion factor from g to mg.

Analytical Methods

Substrates and fermentation samples were characterized in terms of dry matter, moisture content, organic matter and pH according to standard procedures [42]. Reducing sugars (RS) of the solid samples were measured after a solid-liquid extraction with distilled water using the DNS method and expressed per gram of DM [13, 43]. Biodegradability was assessed through two respiration indexes and compared among the different substrates: the dynamic respiration index (DRI24h), which represents the average oxygen uptake rate during the 24 h of maximum activity observed expressed in g O2 kg−1 DM h−1, and the cumulative oxygen consumption index (AT4), which is the cumulative oxygen consumption of the four days after the lag phase expressed in g O2 kg−1 DM, as described elsewhere [40, 41]. All measurements were conducted in triplicates.

Results and Discussion

The characterization of the OFMSW samples used in this study was in line with average literature values (Table 1). During enzymatic hydrolysis, the complex carbohydrates that comprise the OFMSW are converted to monomeric sugars released to the liquid fraction. The efficiency of this conversion process depends on many parameters, such as the enzymatic activities selected, the solids load and the time, among others. However, there is always a remaining solid fraction containing partially hydrolyzed and non-hydrolyzed fibers with the potential to be used in further conversion processes. As can be seen in Table 2, the obtained solid hydrolysate is humid and rich in organic matter. Therefore, a potential substrate for SSF processes that require enough water to promote microbial growth [37]. From the RS measurement, it can be seen that a significant amount of easily accessible sugars remains solubilized in the free water content [13]. The pH is rather acidic, which represents a challenge for growing microorganisms that prefer pH near neutrality such as bacteria, and specifically Bti [36, 37]. Therefore, a pH adjustment step is required before growing Bti as was confirmed during an initial experiment in which unmodified solid hydrolysate was used as a substrate (Fig. 1). In fact, not even the expected amount of around 107 viable cells per g of DM in the sample of day 0 was reached, indicating that cell death was almost immediately. Even though Bti was not observed after 24 h it can be seen how other opportunist microorganisms started consuming oxygen.

Chemical Modification of the pH

The first attempt to modify the pH of the solid hydrolysate was done using chemicals as it is the most straightforward and commonly used methodology. A substance with a strong buffering capacity (CaCO3) was selected over a strong base, such as NaOH, due to the difficulties in monitoring and modifying the pH during the course of SSF processes [37]. To reach a pH of around 7 it was necessary to add 8.5 mL of 1 M CaCO3 to the 90 g of hydrolysate, which only increased the moisture content of the sample by around 2%. Results from this fermentation can be seen in Fig. 2. As the bar graph shows, Bti was not able to thrive and in only 24 h the viable cells were drastically reduced. This can be explained by the drop in pH below 5.6, reported as inhibitory for Bt species [33], as a consequence of the production of organic acids at the early stages of fermentation [36]. Spores appeared at 24 h, reaching the maximum concentration at 72 h as expected [21, 26]. At his point, viable cells could not be measured because they could not be distinguished from opportunist microorganisms in the Petri dishes, which explains the sharp rise of sOUR after 48 h. Even though spores are produced, it has been reported that spores developed in acidic environments are less viable and robust [44]. Increasing the amount of CaCO3, or other substances involves an increase in the moisture content of the sample, which should not exceed 80% [37]. Besides, it would also increase the production cost and difficult the operation at larger process scales. Therefore, it was decided to test a different strategy for pH modification based on the use of high-buffering capacity cosubstrates.

Selection and Screening of Cosubstrates

The use of cosubstrates to improve process efficiency is a widely researched and used practice in the anaerobic digestion of municipal wastes [45, 46]. For instance, the rapid hydrolysis of food waste leads to an inhibitory pH that can be overcome with the use of sewage sludge or animal manure as a cosubstrate [45]. The use of cosubstrates in SSF has been researched to a lesser extent [29, 47]. Nutrient supplementation is more common but it should be highlighted that these studies are rarely conducted at larger scales [48]. For this study, the cosubstrate needed to provide supplemental alkalinity and, ideally, nutrients. It was decided to evaluate only biomaterials in the framework of municipal waste, as it would ease the implementation of such processes in industrial environments. The selected cosubstrates to be studied were: OFMSW digestate, digested sewage sludge and OFMSW compost. Their characterization alongside an average for the solid hydrolysate (Table 2) is presented in Table 3. All three came from large and well-established municipal waste treatment plants, in fact, sewage characterization reported similar values to those obtained in a study performed 5 years ago from the same treatment plant [40]. Montejo et al. [49] evaluated 30 compost samples from 10 MSW treatment plants and reported average values of 22 ± 9, 45 ± 8 and 7.6 ± 0.4 for MC, OM and pH respectively. Thus, comparable to the compost evaluated in this study (Table 2).

All three cosubstrates presented a slightly alkaline pH, around three units above the solid hydrolysate. These alkaline materials are well known for their buffering capacity [45, 50]. Digestate was the cosubstrate presenting the highest amount of OM, but there were no significant differences with sewage sludge. The measure of biodegradability is expressed through the DRI index and is an indirect measure of the biodegradable organic matter content [41]. The AT4 is another useful respiration index that indicates the total oxygen consumed over a four-day period beyond the initial lag phase, which gives a deeper understanding of the sample’s biodegradability [40]. For instance, both digestate and sewage sludge did not present significant differences with the hydrolysate in terms of DRI24h but there was a striking difference in the AT4 values. This might indicate that the hydrolysate contained easily accessible matter but was overall more exhausted. A better insight into the biodegradability potential can be seen in the respiration curves (Fig. 3). The DRI profile of the hydrolysate drops after the first 10 h, while the cosubstrates remain more active during that time leading to higher cumulative oxygen consumptions. Therefore, compost, digestate and sewage sludge represent an increase of 25.6, 128.3 and 137.6% in cumulative oxygen consumption, respectively.

An initial evaluation of the effect of the selected cosubstrates on the SSF of the solid hydrolysate was performed by assessing them at two different wet weight ratios, 25 and 50%. The initial pH (Fig. 4d) for all the mixtures was above six and therefore, not inhibitory for Bti. The final pH, after 72 h of fermentation remained above six except for the mixture containing 25% of compost, which presented a pH of 5.5. Therefore, this mixture was not alkaline enough to surpass the initial pH drop of the fermentation, which led to a drastic reduction of viable cells at the end of the fermentation (Fig. 4c). In terms of oxygen consumption, the maximum values were presented by both mixtures with digestate and were four times higher than the minimum values, which were obtained for the 25% of compost. None of the fermentations reached oxygen-limiting conditions (Fig. 4b), the lowest oxygen concentration recorded was 12% achieved with a 50% of digestate mixture, as expected from the sOUR (Fig. 4a). From Fig. 4, it can be seen how compost was not an adequate cosubstrate. Even though the mixture with 50% presented a pH similar to that of other cosubstrates mixtures, it did not lead to Bti growth but only to sporulation at a yield of almost 1 spore CFU−1 inoculated with a sporulation percentage of 78%. A similar effect has been previously observed when using biowaste digestate as a substrate for growing Bt var kurstaki [26]. This may be explained by the low biodegradability of the sample, as this parameter has been shown to positively influence the growth of Bt species in SSF [22]. There were no significant differences in the growth of Bti in the other cosubstrates mixtures (Fig. 4c), except for 50% of sewage sludge which outperformed. This mixture also led to the highest production of spores (Table 4) which also surpassed previous studies that presented a production similar to the other mixtures (around 30 spores per CFU inoculated) [22].

Process parameters evolution at 0.5 L scale: a sOUR profile, b oxygen profile, c initial and final viable cells and final spore count (initial spore count was 0), and d initial and final pH. Same letters indicate no significantly different parameters for each group (p > 0.05) based on the Tukey test analysis

At this point, it should be highlighted that the cosubstrates were not added sterile, as this would have not made sense in terms of process efficiency due to their nature. Instead, they were added after a thermal hygienization step, which is known to reduce the microbial population of digestate and sewage sludge but not completely, as they contain a great variety of microorganisms that arose from their respective anaerobic digestion processes [51, 52]. This implies that, with the use of this kind of cosubstrates, an autochthonous population of microorganisms is also being added to the solid matrix [22]. A direct effect can be seen in the considerable reduction of the lag phase (Table 4) observed for those mixtures with a higher amount of cosubstrates.

Process Verification and Temperature Evaluation

The increment in microbial activity caused by the use of anaerobically digested cosubstrates can in turn cause an increase in temperature as a consequence of higher metabolic heat production [53]. Besides, one of the major challenges when scaling-up SSF processes is the intense heat generation and its inefficient removal, alongside mass transfer issues [20, 48]. Therefore, for the next experiment, we decided to observe the evolution of temperature during the fermentation course on a three-times increased scale (1.5 L) under uncontrolled temperature conditions. To do so, triplicate reactors for each condition were incubated at room temperature (23 °C ± 2) and sensors were distributed inside the solid matrix to monitor changes. For this experiment, compost was discarded as a cosubstrate due to its poor performance at 0.5 L. This experiment was also conducted to study the reproducibility of the process on a different batch of OFMSW and subsequent enzymatic hydrolysis runs.

Process parameters evolution at 1.5 L scale: a sOUR profile, b average temperature profile, c initial and final viable cells and final spore count (initial spore count was 0), and d initial and final pH. Same letters indicate no significantly different parameters for each group (p > 0.05) based on the Tukey test analysis

As can be seen in Fig. 5a, the maximum sOUR achieved remained consistent with those obtained at 0.5 L (Fig. 4a), which makes sense considering that the airflow supplied per gram of DM was maintained between scales. However, the profiles of the mixtures using sewage sludge changed at 1.5 L presenting narrower peaks that may be explained by different microbial profiles as a consequence of uncontrolled temperature. In terms of Bti growth and sporulation (Fig. 5c), 50% sewage sludge still appeared as the best-performing mixture but by a narrower margin and was not significantly different from the mixture with 50% of digestate in terms of final concentration of viable cells. The sporulation achieved was also 100% and the yield dropped to 150 compared with the 0.5 L scale (Table 4). The 25% of sewage sludge mixture also showed lower performance in comparison with the 0.5 L scale. It led to poor growth of Bti, which was significantly lower than the other mixtures using digestate. This can be explained by the relatively low pH achieved at the end of the fermentation (Fig. 5d). Contrarily, the mixtures using digestate increased their performance concerning the 0.5 L scale. Therefore, sewage sludge as a cosubstrate appeared to be more affected by the scale-up than digestate. This may be explained because digestate has higher alkalinity [54] than sewage sludge [55] and thus prevents more effectively the pH drop at the early stages of the fermentation promoting the development of Bti.

Regarding the average temperature profiles within the packed bed reactors (Fig. 4b), the maximum temperatures reached ranged from 34 °C for the mixture with 50% of digestate and 27 °C for 25% of digestate. Minimum temperatures (21 °C) were achieved by the 25% of sewage sludge, which corresponded to the longer lag phase observed (Table 4). Both mixtures with the higher ratio of cosubstrates increased faster their temperature reaching higher values, especially when using digestate. This can be explained because an increase in metabolic activity leads to an increase in temperature, which in turn stimulates microbial activity. This phenomenon can be observed by comparing how the maximum values for sOUR (Fig. 5a) and temperature (Fig. 5b) are obtained at the same time.

Except for 25% of sewage sludge, process robustness using a different batch of OFMSW has been demonstrated at a larger scale, which is of major importance considering the high variability of this type of waste [5]. Though 50% of sewage sludge reported the best results, both growth and sporulation yield were not reproducible and were lower than 0.5 L. It would be essential to evaluate if this downward trend continues as process scale-up does. It should also be given special attention to the use of a 50% digestate mixture for further scale-up because it led to the highest temperatures. It is well known that in SSF processes temperature increases as the scale does due to mass and heat transfer issues, especially for non-sterile substrates [20, 48]. This becomes even more relevant when the room or ambient temperature increase, for instance with seasonality. Therefore, for digestate, the 25% ratio appears as a lower-risk choice as it presented milder changes in temperature and still retained the pH above 7 (Fig. 5d) with a comparable sporulation yield (Table 4). Also, lower ratios of non-sterile cosubstrates imply lesser microbial load into the reactor and thus lesser competitive pressure microbial benefiting the growth of Bti. The final choice might also be influenced by a deeper characterization of the biopesticide activity because even though spore count is considered an indirect estimation method, it does not completely predict the endotoxic potential [56].

Overall, both digestate and sewage sludge, at a 25% and 50% ratio respectively, appeared as suitable cosubstrates for the SSF of an acidic hydrolysate. This gives flexibility to the process and the final choice would depend on the availability of each cosubstrate. From an urban solid waste biorefinery perspective, the use of digestate from the AD process of OFMSW makes more sense as it would lead to better process integration [6]. For instance, the higher quality OFMSW received into the treatment plant can be used for the enzymatic hydrolysis coupled with SSF and submerged fermentation for the liquid fraction while the OFMSW with less quality could be treated through AD. This leads to a multiplatform configuration that not only enhances the recovery of resources but also provides the biorefinery with more flexibility and resources to adapt to energy requirements and price fluctuation [57, 58]. However, digested sewage sludge is a far more abundant material that in many cases requires treatment before its safe disposal, and therefore novel valorization pathways.

Conclusion

The use of alkaline cosubstrates has been implemented as a successful and reproducible strategy to overcome the pH drop during the SSF of Bacillus thuringiensis var. israelensis using solid hydrolysate of OFMSW as substrate. Two byproducts of urban waste treatments, digestate and digested sewage sludge, appeared as adequate cosubstrates providing the process with certain implementation flexibility. Spores concentration of 1.1 × 109 spores g−1 DM and 6.4 × 108 spores g−1 DM were obtained for sewage sludge and digestate respectively, which corresponds to yields of 112 and 48 spores per inoculated Bti cell. This work represents a further step in novel valorization options for the organic fraction of municipal solid waste, in line with a biorefinery scenario for waste management as the future requires. Future studies have to evaluate the biopesticide activity and safety of the final product, as well as its formulation.

Data Availability

Enquiries about data availability should be directed to the authors.

References

Kaza, S., Yao, L., Bhada-Tata, P., Van Woerden, F.: What a waste 2.0: a global snapshot of solid waste management to 2050. The World Bank, Washington, DC (2018)

Wilson, D.C.: Development drivers for waste management. Waste Manag. Res. 25, 198–207 (2007). https://doi.org/10.1177/0734242X07079149

Mayer, F., Bhandari, R., Gäth, S.A., Himanshu, H., Stobernack, N.: Economic and environmental life cycle assessment of organic waste treatment by means of incineration and biogasification. Is source segregation of biowaste justified in Germany? Sci. Total Environ. (2020). https://doi.org/10.1016/j.scitotenv.2020.137731

Cerda, A., Artola, A., Font, X., Barrena, R., Gea, T., Sánchez, A.: Composting of food wastes: status and challenges. Bioresour. Technol. 248, 57–67 (2018). https://doi.org/10.1016/j.biortech.2017.06.133

Campuzano, R., González-Martínez, S.: Characteristics of the organic fraction of municipal solid waste and methane production: a review. Waste Manag. 54, 3–12 (2016). https://doi.org/10.1016/j.wasman.2016.05.016

Molina-Peñate, E., Artola, A., Sánchez, A.: Organic municipal waste as feedstock for biorefineries: bioconversion technologies integration and challenges. Rev. Environ. Sci. Biotechnol. 21, 247–267 (2022). https://doi.org/10.1007/s11157-021-09605-w

Jowitt, S.M., Mudd, G.M., Thompson, J.F.H.: Future availability of non-renewable metal resources and the influence of environmental, social, and governance conflicts on metal production. Commun. Earth Environ. (2020). https://doi.org/10.1038/s43247-020-0011-0

Mahmoodi, P., Karimi, K., Taherzadeh, M.J.: Hydrothermal processing as pretreatment for efficient production of ethanol and biogas from municipal solid waste. Bioresour. Technol. 261, 166–175 (2018). https://doi.org/10.1016/j.biortech.2018.03.115

Alvira, P., Tomás-Pejó, E., Ballesteros, M., Negro, M.J.: Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour. Technol. 101, 4851–4861 (2010). https://doi.org/10.1016/j.biortech.2009.11.093

López-Gómez, J.P., Latorre-Sánchez, M., Unger, P., Schneider, R., Coll Lozano, C., Venus, J.: Assessing the organic fraction of municipal solid wastes for the production of lactic acid. Biochem. Eng. J. (2019). https://doi.org/10.1016/j.bej.2019.107251

Izaguirre, J.K., da Fonseca, M.M.R., Fernandes, P., Villarán, M.C., Castañón, S., Cesário, M.T.: Upgrading the organic fraction of municipal solid waste to poly(3-hydroxybutyrate). Bioresour. Technol. 290, 121785 (2019). https://doi.org/10.1016/j.biortech.2019.121785

Ebrahimian, F., Karimi, K., Kumar, R.: Sustainable biofuels and bioplastic production from the organic fraction of municipal solid waste. Waste Manag. 116, 40–48 (2020). https://doi.org/10.1016/j.wasman.2020.07.049

Molina-Peñate, E., Sánchez, A., Artola, A.: Enzymatic hydrolysis of the organic fraction of municipal solid waste: optimization and valorization of the solid fraction for Bacillus thuringiensis biopesticide production through solid-state fermentation. Waste Manag. 137, 304–311 (2022). https://doi.org/10.1016/j.wasman.2021.11.014

Yang, X., Choi, H.S., Park, C., Kim, S.W.: Current states and prospects of organic waste utilization for biorefineries. Renew. Sustain. Energy Rev. 49, 335–349 (2015). https://doi.org/10.1016/j.rser.2015.04.114

Venkata Mohan, S., Nikhil, G.N., Chiranjeevi, P., Nagendranatha Reddy, C., Rohit, M.V., Kumar, A.N., Sarkar, O.: Waste biorefinery models towards sustainable circular bioeconomy: critical review and future perspectives. Bioresour. Technol. 215, 2–12 (2016). https://doi.org/10.1016/j.biortech.2016.03.130

López-Gómez, J.P., Unger, P., Schneider, R., Venus, J.: From upstream to purification: production of lactic acid from the organic fraction of municipal solid waste. Waste Biomass Valoriz. (2020). https://doi.org/10.1007/s12649-020-00992-9

Stylianou, E., Pateraki, C., Ladakis, D., Cruz-Fernández, M., Latorre-Sánchez, M., Coll, C., Koutinas, A.: Evaluation of organic fractions of municipal solid waste as renewable feedstock for succinic acid production. Biotechnol. Biofuels 13, 1–16 (2020). https://doi.org/10.1186/s13068-020-01708-w

Izaguirre, J.K., Barañano, L., Castañón, S., Santos, J.A.L., Cesário, M.T., da Fonseca, M.M.R., Alkorta, I., Garbisu, C.: Economic and environmental assessment of bacterial poly(3-hydroxybutyrate) production from the organic fraction of municipal solid waste. Bioresour. Bioprocess. 8, 1–12 (2021). https://doi.org/10.1186/S40643-021-00392-4/FIGURES/2

Ebrahimian, F., Denayer, J.F.M., Karimi, K.: Efficient coproduction of butanol, ethanol, and biohydrogen from municipal solid waste through a cocultivated biorefinery. Energy Convers. Manag. 255, 115303 (2022). https://doi.org/10.1016/J.ENCONMAN.2022.115303

Thomas, L., Larroche, C., Pandey, A.: Current developments in solid-state fermentation. Biochem. Eng. J. 81, 146–161 (2013). https://doi.org/https://doi.org/https://doi.org/10.1016/j.bej.2013.10.013

Cerda, A., Mejias, L., Rodríguez, P., Rodríguez, A., Artola, A., Font, X., Gea, T., Sánchez, A.: Valorisation of digestate from biowaste through solid-state fermentation to obtain value added bioproducts: a first approach. Bioresour Technol. 271, 409–416 (2019). https://doi.org/10.1016/j.biortech.2018.09.131

Mejias, L., Estrada, M., Barrena, R., Gea, T.: A novel two-stage aeration strategy for Bacillus thuringiensis biopesticide production from biowaste digestate through solid-state fermentation. Biochem. Eng. J. 161, 107644 (2020). https://doi.org/10.1016/j.bej.2020.107644

Yazid, N.A., Barrena, R., Komilis, D., Sánchez, A.: Solid-state fermentation as a novel paradigm for organic waste valorization: a review. Sustainability 9, 224 (2017). https://doi.org/10.3390/su9020224

Ballardo, C., Barrena, R., Artola, A., Sánchez, A.: A novel strategy for producing compost with enhanced biopesticide properties through solid-state fermentation of biowaste and inoculation with Bacillus thuringiensis. Waste Manag. 70, 53–58 (2017). https://doi.org/10.1016/j.wasman.2017.09.041

Sala, A., Artola, A., Sánchez, A., Barrena, R.: Rice husk as a source for fungal biopesticide production by solid-state fermentation using B. bassiana and T. harzianum. Bioresour. Technol. 296, 122322 (2020). https://doi.org/10.1016/j.biortech.2019.122322

Rodríguez, P., Cerda, A., Font, X., Sánchez, A., Artola, A.: Valorisation of biowaste digestate through solid state fermentation to produce biopesticides from Bacillus thuringiensis. Waste Manag. 93, 63–71 (2019). https://doi.org/10.1016/j.wasman.2019.05.026

Martínez-Avila, O., Muñoz-Torrero, P., Sánchez, A., Font, X., Barrena, R.: Valorization of agro-industrial wastes by producing 2-phenylethanol via solid-state fermentation: influence of substrate selection on the process. Waste Manag. 121, 403–411 (2021). https://doi.org/10.1016/j.wasman.2020.12.036

Rivero, C.P., Hu, Y., Kwan, T.H., Webb, C., Theodoropoulos, C., Daoud, W., Lin, C.S.K.: Bioplastics from solid waste. Curr. Dev. Biotechnol. Bioeng. Solid Waste Manag. (2017)

Jiménez-Peñalver, P., Gea, T., Sánchez, A., Font, X.: Production of sophorolipids from winterization oil cake by solid-state fermentation: optimization, monitoring and effect of mixing. Biochem. Eng. J. 115, 93–100 (2016). https://doi.org/10.1016/j.bej.2016.08.006

Eras-Muñoz, E., Farré, A., Sánchez, A., Font, X., Gea, T.: Microbial biosurfactants: a review of recent environmental applications. Bioengineered 13, 12365–12391 (2022). https://doi.org/10.1080/21655979.2022.2074621

Ballardo, C., Abraham, J., Barrena, R., Artola, A., Gea, T., Sánchez, A.: Valorization of soy waste through SSF for the production of compost enriched with Bacillus thuringiensis with biopesticide properties. J. Environ. Manag. 169, 126–131 (2016). https://doi.org/10.1016/J.JENVMAN.2015.12.029

Prakash, J., Sharma, R., Patel, S.K.S., Kim, I.W., Kalia, V.C.: Bio-hydrogen production by co-digestion of domestic wastewater and biodiesel industry effluent. PLoS ONE. 13, e0199059 (2018). https://doi.org/10.1371/JOURNAL.PONE.0199059

Jallouli, W., Driss, F., Fillaudeau, L., Rouis, S.: Review on biopesticide production by Bacillus thuringiensis subsp. kurstaki since: focus on bioprocess parameters. Process Biochem. 98, 224–232 (2020). https://doi.org/10.1016/j.procbio.2020.07.023

Biopesticides Market - Growth, Trends, C.O.V.I.D.-., Impact: and Forecasts (2021). –2026 https://www.mordorintelligence.com/industry-reports/global-biopesticides-market-industry

Bravo, A., Likitvivatanavong, S., Gill, S.S., Soberón, M.: Bacillus thuringiensis: a story of a successful bioinsecticide. Insect Biochem. Mol. Biol. 41, 423–431 (2011). https://doi.org/10.1016/j.ibmb.2011.02.006

Foda, M.S., Salama, H.S., Selim, M.: Factors affecting growth physiology of Bacillus thuringiensis. Appl. Microbiol. Biotechnol. 22, 50–52 (1985)

Kumar, V., Ahluwalia, V., Saran, S., Kumar, J., Patel, A.K., Singhania, R.R.: Recent developments on solid-state fermentation for production of microbial secondary metabolites: challenges and solutions. Bioresour. Technol. 323, 124566 (2021). https://doi.org/10.1016/j.biortech.2020.124566

Sala, A., Barrena, R., Sánchez, A., Artola, A.: Fungal biopesticide production: process scale-up and sequential batch mode operation with Trichoderma harzianum using agro-industrial solid wastes of different biodegradability. Chem. Eng. J. 425, 131620 (2021). https://doi.org/10.1016/J.CEJ.2021.131620

Zhang, W., Qiu, L., Gong, A., Cao, Y., Wang, B.: Solid-state Fermentation of Kitchen Waste for Production of Bacillus thuringiensis-based Bio-pesticide. BioResources 8, 1124–1135 (2013). https://doi.org/10.15376/biores.8.1.1124-1135

Mejias, L., Komilis, D., Gea, T., Sánchez, A.: The effect of airflow rates and aeration mode on the respiration activity of four organic wastes: implications on the composting process. Waste Manag. 65, 22–28 (2017). https://doi.org/10.1016/j.wasman.2017.04.008

Ponsá, S., Gea, T., Sánchez, A.: Different indices to express biodegradability in organic solid wastes. J. Environ. Qual. 39, 706–712 (2010). https://doi.org/10.2134/jeq2009.0294

Thompson, W.H., Leege, P.B., Millner, P.D., Watson, M.E.: Test methods for the examination of composting and compost.United States Compost. Counc. Res. Educ. Found. United States Dep. Agric. (2001)

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959). https://doi.org/10.1021/ac60147a030

Saleh, S.M., Harris, R.F., Allen, O.N.: Fate of Bacillus thuringiensis in soil: effect of soil pH and organic amendment. Can. J. Microbiol. 16, 677–680 (1970). https://doi.org/10.1139/m70-116

Karki, R., Chuenchart, W., Surendra, K.C., Shrestha, S., Raskin, L., Sung, S., Hashimoto, A., Kumar, S.: Bioresource technology anaerobic co-digestion: current status and perspectives. Bioresour. Technol. 330, 125001 (2021)

Kasinath, A., Fudala-Ksiazek, S., Szopinska, M., Bylinski, H., Artichowicz, W., Remiszewska-Skwarek, A., Luczkiewicz, A.: Biomass in biogas production: pretreatment and codigestion. Renew. Sustain. Energy Rev. 150, 111509 (2021). https://doi.org/10.1016/j.rser.2021.111509

Fleuri, L.F., de Oliveira, M.C., de Lara Campos Arcuri, M., Capoville, B.L., Pereira, M.S., Delgado, C.H.O., Novelli, P.K.: Production of fungal lipases using wheat bran and soybean bran and incorporation of sugarcane bagasse as a co-substrate in solid-state fermentation. Food Sci. Biotechnol. 23, 1199–1205 (2014). https://doi.org/10.1007/s10068-014-0164-7

Soccol, C.R., Costa, E.S.F., da, Letti, L.A.J., Karp, S.G., Woiciechowski, A.L., de Vandenberghe, L.P.: Recent developments and innovations in solid state fermentation. Biotechnol. Res. Innov. 1, 52–71 (2017). https://doi.org/10.1016/j.biori.2017.01.002

Montejo, C., Costa, C., Márquez, M.C.: Influence of input material and operational performance on the physical and chemical properties of MSW compost. J. Environ. Manag. 162, 240–249 (2015). https://doi.org/10.1016/j.jenvman.2015.07.059

García-Gil, J.C., Ceppi, S.B., Velasco, M.I., Polo, A., Senesi, N.: Long-term effects of amendment with municipal solid waste compost on the elemental and acidic functional group composition and pH-buffer capacity of soil humic acids. Geoderma. 121, 135–142 (2004). https://doi.org/10.1016/J.GEODERMA.2003.11.004

Astals, S., Venegas, C., Peces, M., Jofre, J., Lucena, F., Mata-Alvarez, J.: Balancing hygienization and anaerobic digestion of raw sewage sludge. Water Res. 46, 6218–6227 (2012). https://doi.org/10.1016/J.WATRES.2012.07.035

Ndubuisi-Nnaji, U.U., Ofon, U.A., Ekponne, N.I., Offiong, N.A.O., Offiong, N.A.O.: Improved biofertilizer properties of digestate from codigestion of brewer’s spent grain and palm oil mill effluent by manure supplementation. Sustain. Environ. Res. 30, 1–11 (2020). https://doi.org/10.1186/S42834-020-00056-6/TABLES/5

Arora, S., Singh, P., Rani, R., Ghosh, S.: Oxygen uptake rate as a tool for on-line estimation of cell biomass and bed temperature in a novel solid-state fermentation bioreactor. Bioprocess. Biosyst. Eng. 41, 917–929 (2018). https://doi.org/10.1007/S00449-018-1923-2/FIGURES/9

Michele, P., Giuliana, D., Carlo, M., Sergio, S., Fabrizio, A.: Optimization of solid state anaerobic digestion of the OFMSW by digestate recirculation: a new approach. Waste Manag. 35, 111–118 (2015). https://doi.org/10.1016/J.WASMAN.2014.09.009

Fonoll, X., Astals, S., Dosta, J., Mata-Alvarez, J.: Anaerobic co-digestion of sewage sludge and fruit wastes: evaluation of the transitory states when the co-substrate is changed. Chem. Eng. J. 262, 1268–1274 (2015). https://doi.org/10.1016/J.CEJ.2014.10.045

De Montiel, L.T., Tyagi, M., Valero, R.D.: Wastewater treatment sludge as a raw material for the production of Bacillus thuringiensis based biopesticides. Water Res. 35, 3807–3816 (2001). https://doi.org/10.1016/S0043-1354(01)00103-8

Moncada, B., Aristizábal, J., Cardona, M.V.: Design strategies for sustainable biorefineries. Biochem. Eng. J. 116, 122–134 (2016). https://doi.org/10.1016/j.bej.2016.06.009

Alibardi, L., Astrup, T.F., Asunis, F., Clarke, W.P., De Gioannis, G., Dessì, P., Lens, P.N.L., Lavagnolo, M.C., Lombardi, L., Muntoni, A., Pivato, A., Polettini, A., Pomi, R., Rossi, A., Spagni, A., Spiga, D.: Organic waste biorefineries: looking towards implementation. Waste Manag. 114, 274–286 (2020). https://doi.org/10.1016/j.wasman.2020.07.010

Acknowledgements

Esther Molina thanks Generalitat de Catalunya for her pre-doctoral Grant (DI 7, 2019). The authors thank ASA Spezialenzyme GmbH, for providing the enzymatic cocktail; Mancomunitat de la Plana, for providing the OFMSW; Consorci per a la Gestió dels Residus del Vallès Oriental, for providing the digestate; Àrea metropolitana de Barcelona for the OFMSW compost; and Aigues Sabadell; for providing the sewage sludge.

Funding

Open Access Funding provided by Universitat Autònoma de Barcelona. This research was funded by the Horizon 2020 research and innovation Program within the SCALIBUR project (Grant Agreement No 817788).

Author information

Authors and Affiliations

Contributions

EMP, AS and AA contributed to the study conception and design. Material preparation, data collection and analysis were performed by EMP and NA. The first draft of the manuscript was written by EMP and AS and AA commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Molina-Peñate, E., Arenòs, N., Sánchez, A. et al. Bacillus thuringiensis Production Through Solid-State Fermentation Using Organic Fraction of Municipal Solid Waste (OFMSW) Enzymatic Hydrolysate. Waste Biomass Valor 14, 1433–1445 (2023). https://doi.org/10.1007/s12649-022-01978-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01978-5