Abstract

Purpose

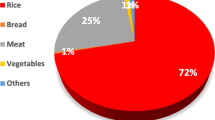

Sugars production from secondary resources has been recognised as a strategic process unit within the valorisation routes of waste. In this context, food waste (FW) as an abundant waste stream with elevated concentrations of glucose and carbohydrates (cellulose, starch) could stand as a suitable feedstock for saccharification. To evaluate this new potential application of FW, FW enzymatic hydrolysis was investigated via non-commercial enzymes.

Methods

FW was subjected to enzymatic hydrolysis by an amylolytic and a cellulolytic formulation under different enzyme loadings. At the optimum conditions, the time course of glucose production during enzymatic hydrolysis was also studied. In order to enlighten the viability of bioethanol production process from FW, the experimental results were evaluated in terms of cost of enzymes per liter of bioethanol produced.

Results

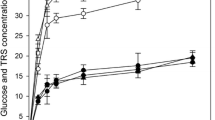

81% starch hydrolysis was achieved after 1 h of hydrolysis by 45 μL amylolytic enzyme NS22109/g starch at 65 °C. With regard to the effect of cellulase loading, 175 μL NS22177/g cellulose achieved 50% saccharification yield. Further increase of enzyme dosage just slightly increased the yield. More specifically, by increasing the enzyme loading 540%, the resulting saccharification efficiency increased by just 16%. Last, the enzyme cost per ethanol yield was almost 3.5 times lower when just amylolytic enzymes were used for similar ethanol yields.

Conclusion

Enzymatic hydrolysis of starch and cellulose present in FW proved to be technically efficient providing high yields. Nevertheless, the difference in the economic weight of the use of amylolytic and/or cellulolytic enzymes strongly influences the viability of FW valorization via bioethanol production.

Graphic Abstract

Similar content being viewed by others

Abbreviations

- EU:

-

European Union

- FW:

-

Food waste

- GOX–PER:

-

Glucose oxidase–peroxidase

- MSW:

-

Municipal solid waste

- RSM:

-

Response surface methodology

- UEST:

-

Unit of Environmental Science and Technology

- GHG:

-

Greenhouse gas

References

Fatmawati, A., Gunawan, K.Y., Hadiwijaya, F.A.: Hydrolysis of alkaline pretreated banana peel. Mater. Sci. Eng. Conf. Ser. 273(1), 012011 (2017). https://doi.org/10.1088/1757-899X/245/1/012011

Moon, H.C., Song, I.S., Kim, J.C., Shirai, Y., Lee, D.H., Kim, J.K., Chung, S.O., Kim, D.H., Oh, K.K., Cho, Y.S.: Enzymatic hydrolysis of food waste and ethanol fermentation. Int. J. Energy Res. 33(2), 164–172 (2009)

Carmona-Cabello, M., Garcia, I.L., Leiva-Candia, D., Dorado, M.P.: Valorization of food waste based on its composition through the concept of biorefinery. Curr. Opin. Green. Sustain. Chem. 14, 67–79 (2018)

Ravindran, R., Jaiswal, A.K.: Exploitation of food industry waste for high-value products. Trends Biotechnol. 34(1), 58–69 (2016)

Kumar, V., Longhurst, P.: Recycling of food waste into chemical building blocks. Curr. Opin. Green Sustain. Chem. 13, 118–122 (2018)

Pleissner, D., Lin, C.S.K.: Valorisation of food waste in biotechnological processes. Sustain. Chem. Processes 1, 1–6 (2013)

Cekmecelioglu, D., Uncu, O.N.: Kinetic modeling of enzymatic hydrolysis of pretreated kitchen wastes for enhancing bioethanol production. Waste Manag. 33(3), 735–739 (2013)

Hafid, H.S., Abdul Rahman, N., Md Shah, U.K., Samsu Baharudin, A., Zakaria, R.: Direct utilization of kitchen waste for bioethanol production by separate hydrolysis and fermentation (SHF) using locally isolated yeast. Int. J. Green Energy 13(3), 248–259 (2016)

Hafid, H.S., Nor’Aini, A.R., Mokhtar, M.N., Talib, A.T., Baharuddin, A.S., Umi Kalsom, M.S.: Over production of fermentable sugar for bioethanol production from carbohydrate-rich malaysian food waste via sequential acid-enzymatic hydrolysis pretreatment. Waste Manag. 67, 95–105 (2017)

Ntaikou, I., Menis, N., Alexandropoulou, M., Antonopoulou, G., Lyberatos, G.: Valorization of kitchen biowaste for ethanol production via simultaneous saccharification and fermentation using co-cultures of the yeasts saccharomyces cerevisiae and pichia stipitis. Bioresour. Technol. 263, 75–83 (2018)

Tang, Y.Q., Koike, Y., Liu, K., An, M.Z., Morimura, S., Wu, X.L., Kida, K.: Ethanol production from kitchen waste using the flocculating yeast saccharomyces cerevisiae strain KF-7. Biomass Bioenergy 32(11), 1037–1045 (2008)

Uçkun Kiran, E., Liu, Y.: Bioethanol production from mixed food waste by an effective enzymatic pretreatment. Fuel 159, 463–469 (2015)

Anwar Saeed, M., Ma, H., Yue, S., Wang, Q., Tu, M.: Concise review on ethanol production from food waste: development and sustainability. Environ. Sci. Pollut. Res. 25(29), 28851–28863 (2018)

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., Crocker, D.: National Renewable Energy Laboratory (U.S.) Determination of structural carbohydrates and lignin in biomass laboratory analytical procedure (LAP): issue date, 4/25/2008. Golden, Colo: National Renewable Energy Laboratory (2008)

Xiao, Z., Storms, R., Tsang, A.: A quantitative starch-iodine method for measuring alpha-amylase and glucoamylase activities. Anal. Biochem. 351(1), 146–148 (2006)

Ghose, T.K.: Measurement of cellulase activities. Pure Appl. Chem. 59(2), 257–268 (1987)

Sarkar, N., Ghosh, S.K., Bannerjee, S., Aikat, K.: Bioethanol production from agricultural wastes: an overview. Renew. Energy 37(1), 19–27 (2012)

Yan, S., Wang, P., Zhai, Z., Yao, J.: Fuel ethanol production from concentrated food waste hydrolysates in immobilized cell reactors by saccharomyces cerevisiae H058. J. Chem. Technol. Biotechnol. 86(5), 731–738 (2011)

Yan, S., Yao, J., Yao, L., Zhi, Z., Chen, X., Wu, J.: Fed batch enzymatic saccharification of food waste improves the sugar concentration in the hydrolysates and eventually the ethanol fermentation by saccharomyces cerevisiae H058. Braz. Arch. Biol. Technol. 55(2), 183–192 (2012)

Mahmoodi, P., Karimi, K., Taherzadeh, M.J.: Hydrothermal processing as pretreatment for efficient production of ethanol and biogas from municipal solid waste. Bioresour. Technol. 261, 166–175 (2018)

Koike, Y., An, M.Z., Tang, Y.Q., Syo, T., Osaka, N., Morimura, S., Kida, K.: Production of fuel ethanol and methane from garbage by high-efficiency two-stage fermentation process. J. Biosci. Bioeng. 108(6), 508–512 (2009)

Kim, J.H., Lee, J.C., Pak, D.: Feasibility of producing ethanol from food waste. Waste Manag. 31(9–10), 2121–2125 (2011)

Banerjee, S., Mudliar, S., Sen, R., Giri, B., Satpute, D., Chakrabarti, T., Pandey, R.A.: Commercializing lignocellulosic bioethanol: technology bottlenecks and possible remedies. Biofuel Bioprod. Biorefin. 4(1), 77–93 (2010)

Pandiyan, K., Singh, A., Singh, S., Saxena, A.K., Nain, L.: Technological interventions for utilization of crop residues and weedy biomass for second generation bio-ethanol production. Renew. Energy 132, 723–741 (2019)

Gomes, D.G., Serna-Loaiza, S., Cardona, C.A., Gama, M., Domingues, L.: Insights into the economic viability of cellulases recycling on bioethanol production from recycled paper sludge. Bioresour. Technol. 267, 347–355 (2018)

Battista, F., Bolzonella, D.: Some critical aspects of the enzymatic hydrolysis at high dry-matter content: a review. Biofuel. Bioprod. Biorefin. 12(4), 711–723 (2018)

Chovau, S., Degrauwe, D., Van Der Bruggen, B.: Critical analysis of techno-economic estimates for the production cost of lignocellulosic bio-ethanol. Renew. Sustain. Energy Rev. 26, 307–321 (2013)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Salimi, E., Saragas, K., Taheri, M.E. et al. The Role of Enzyme Loading on Starch and Cellulose Hydrolysis of Food Waste. Waste Biomass Valor 10, 3753–3762 (2019). https://doi.org/10.1007/s12649-019-00826-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00826-3