Abstract

Dielectric Barrier Discharge (DBD) can be used to produce a large volume of non-thermal plasma at atmospheric pressure. Such plasmas are sources of highly reactive species (radicals, ozone, atoms, ions and excited molecules). Due to its characteristics, the DBD plasma can be applied for the pretreatment of lignocellulosic materials, in order to extract lignin that prevents the access to remained fermentable sugars in the biomass. In this context, an alternative method for pretreatment of lignocellulosic material in an in-liquid DBD plasma reactor using non-contact electrodes, working with atmospheric air, has been proposed. After the pretreatment, the solids were washed and submitted to enzymatic hydrolysis with a commercial enzyme complex, at 10 FPU/g of pretreated biomass and 50 g/L solids concentration (dry basis), for 72 h. The release of fermentable sugars was measured, comparing the samples obtained with and without plasma treatment. The highest sugar release was achieved using the plasma-in-liquid pretreatment in a single step, with glucose and xylose yields of 51.3 and 38.5%, respectively, after enzymatic hydrolysis. Thus, an effective pretreatment was developed to be applied to biomass such as: corn cob, sugarcane bagasse, bamboo, eucalyptus, etc., in order to reduce the environmental impact and, at the same time, produce biofuels.

Graphic Abstract

Similar content being viewed by others

References

Alex Marvin, W., Schmidt, L.D., Benjaafar, S., Tiffany, D.G., Daoutidis, P.: Economic optimization of a lignocellulosic biomass-to-ethanol supply chain. Chem. Eng. Sci. 67, 68–79 (2012). https://doi.org/10.1016/j.ces.2011.05.055

Maas, R.H.W., Bakker, R.R., Boersma, A.R., Bisschops, I., Pels, J.R., de Jong, E., Weusthuis, R.A., Reith, H.: Pilot-scale conversion of lime-treated wheat straw into bioethanol: quality assessment of bioethanol and valorization of side streams by anaerobic digestion and combustion. Biotechnol. Biofuels 1, 1 (2008). https://doi.org/10.1186/1754-6834-1-14

Arantes, V., Saddler, J.N.: Access to cellulose limits the efficiency of enzymatic hydrolysis: the role of amorphogenesis. Biotechnol. Biofuels 3, 1–11 (2010). https://doi.org/10.1186/1754-6834-3-1

Lopes, M.L., Cristina, S., Paulillo, D.L., Godoy, A., Cherubin, R.A., Lorenzi, M.S., Henrique, F., Giometti, C., Bernardino, C.D., Berbert, H., Neto, D.A., Amorim, H.V.De: Biotechnology and industry microbiology ethanol production in Brazil : a bridge between science and industry. Brazilian J. Microbiol. 47, 64–76 (2016). https://doi.org/10.1016/j.bjm.2016.10.003

De Guilherme, A.A., Dantas, P.V.F., Soares, J.C.J., Dos Santos, E.S., Fernandes, F.A.N., De Macedo, G.R.: Pretreatments and enzymatic hydrolysis of sugarcane bagasse aiming at the enhancement of the yield of glucose and xylose. Braz. J. Chem. Eng. 34, 937–947 (2017). https://doi.org/10.1590/0104-6632.20170344s20160225

Aditiya, H.B., Mahlia, T.M.I., Chong, W.T., Nur, H., Sebayang, A.H.: Second generation bioethanol production : a critical review. Renew. Sustain. Energy Rev. 66, 631–653 (2016). https://doi.org/10.1016/j.rser.2016.07.015

Jönsson, L.J., Alriksson, B., Nilvebrant, N., Wear, S., Paper, C., Effects, S.: Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol. Biofuels. 6, 16 (2013). https://doi.org/10.1186/1754-6834-6-16

Taherzadeh, M.J., Karimi, K.: Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: a review. (2008)

Kumar, P., Kumar, P., Barrett, D.M., Barrett, D.M., Delwiche, M.J., Delwiche, M.J., Stroeve, P., Stroeve, P.: Methods for pretreatment of lignocellulosic biomass for ef cient hydrolysis and biofuel production. Ind. Eng. Chem. 48, 3713–3729 (2009). https://doi.org/10.1021/ie801542g

Kriegseis, J., Möller, B., Grundmann, S., Tropea, C.: Capacitance and power consumption quantification of dielectric barrier discharge (DBD) plasma actuators. J. Electrostat. 69, 302–312 (2011). https://doi.org/10.1016/j.elstat.2011.04.007

Kogelschatz, U., Eliasson, B., Egli, W., Kogelschatz, U., Eliasson, B., Principle, W.E.D.D.: Dielectric-barrier discharges. Principle and Applications. HAL Id : jpa-00255561. (1997)

Bruggeman, P., Leys, C.: Non-thermal plasmas in and in contact with liquids. J. Phys. D 42, 053001. https://doi.org/10.1088/0022-3727/42/5/053001

Žigon, J., Petrič, M., Dahle, S.: Dielectric barrier discharge (DBD) plasma pretreatment of lignocellulosic materials in air at atmospheric pressure for their improved wettability: a literature review. Holzforschung 72, 979–991 (2018). https://doi.org/10.1515/hf-2017-0207

Fiebrandt, M., Lackmann, J.W., Stapelmann, K.: From patent to product? 50 years of low-pressure plasma sterilization. Plasma Process. Polym. 15(12), 1800139 (2018). https://doi.org/10.1002/ppap.201800139

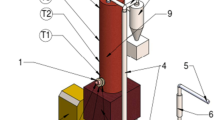

Miranda, F.S., Maciel, H.S., Skane, K.K., Santos, L.V., Santos, P.M., Silva, J.S., Pessoa, R.S.: Reator de plasma de descarga por barreira dielétrica, processo e sistema de pré-tratamento de biomassa lignocelulósica—BR1O2012 031364–2 A2, (2014)

Lucas, J., Lucas, P., Mercier, T.Le, Rollat, A., Davenport, W.: Rare earths science, technology, production and use. Elsevier, Amsterdam (2015)

Zhu, Y., Malten, M., Torry-Smith, M., McMillan, J.D., Stickel, J.J.: Calculating sugar yields in high solids hydrolysis of biomass. Bioresour. Technol. 102, 2897–2903 (2011). https://doi.org/10.1016/j.biortech.2010.10.134

Sluiter, J.B., Chum, H., Gomes, A.C., Tavares, R.P.A., Azevedo, V., Pimenta, M.T.B., Rabelo, S.C., Marabezi, K., Curvelo, A.A.S., Alves, A.R., Garcia, W.T., Carvalho, W., Esteves, P.J., Mendonça, S., Oliveira, P.A., Ribeiro, J.A.A., Mendes, T.D., Vicentin, M.P., Duarte, C.L., Mori, M.N.: Evaluation of Brazilian sugarcane bagasse characterization: an interlaboratory comparison study. J. AOAC Int. 99, 579–585 (2016). https://doi.org/10.5740/jaoacint.15-0063

Mok, W.S.L., Antal, M.J.: Uncatalyzed solvolysis of whole biomass hemicellulose by hot compressed liquid water. Ind. Eng. Chem. Res. 31, 1157–1161 (1992). https://doi.org/10.1021/ie00004a026

Laroussi, M.: Low temperature plasma-based sterilization: overview and state-of-the-art. Plasma Process. Polym. 2, 391–400 (2005). https://doi.org/10.1002/ppap.200400078

Rutala, W.A., Weber, D.J.: Disinfection, sterilization, and antisepsis: an overview. Am. J. Infect. Control. 47, A3–A9 (2019). https://doi.org/10.1016/j.ajic.2019.01.018

Wright, A., Bandulasena, H., Ibenegbu, C., Leak, D., Holmes, T., Zimmerman, W., Shaw, A., Iza, F.: Dielectric barrier discharge plasma microbubble reactor for pretreatment of lignocellulosic biomass. AIChE J. 64, 3803–3816 (2018). https://doi.org/10.1002/aic.16212

Grous, W.R., Converse, A.O., Grethlein, H.E.: Effect of steam explosion pretreatment on pore size and enzymatic hydrolysis of poplar. Enzyme Microb. Technol. 8, 274–280 (1986). https://doi.org/10.1016/0141-0229(86)90021-9

Li, J., Henriksson, G., Gellerstedt, G.: Lignin depolymerization/repolymerization and its critical role for delignification of aspen wood by steam explosion. Bioresour. Technol. 98, 3061–3068 (2007). https://doi.org/10.1016/j.biortech.2006.10.018

Vanholme, R., Demedts, B., Morreel, K., Ralph, J., Boerjan, W.: Lignin biosynthesis and structure. Plant Physiol. 153, 895–905 (2010). https://doi.org/10.1104/pp.110.155119

Singh, R., Shukla, A., Tiwari, S., Srivastava, M.: A review on delignification of lignocellulosic biomass for enhancement of ethanol production potential. Renew. Sustain. Energy Rev. 32, 713–728 (2014). https://doi.org/10.1016/j.rser.2014.01.051

Reid, J.S.G.: Carbohydrate metabolism structural carbohydrates. Academic Press, London (1997)

Kataria, R., Ghosh, S.: NaOH pretreatment and enzymatic hydrolysis of saccharum spontaneum for reducing sugars production. Energy Sources A 36, 1028–1035 (2014). https://doi.org/10.1080/15567036.2010.551268

Zheng, Y., Lin, H.M., Tsao, G.T.: Pretreatment for cellulose hydrolysis by carbon dioxide explosion. Biotechnol. Prog. 14, 890–896 (1998). https://doi.org/10.1021/bp980087g

Vidal, P.F., Molinier, J.: Ozonolysis of lignin - Improvement of in vitro digestibility of poplar sawdust. Biomass. 16, 1–17 (1988). https://doi.org/10.1016/0144-4565(88)90012-1

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Miranda, F.S., Rabelo, S.C., Pradella, J.G.C. et al. Plasma in-Liquid Using Non-contact Electrodes: A Method of Pretreatment to Enhance the Enzymatic Hydrolysis of Biomass. Waste Biomass Valor 11, 4921–4931 (2020). https://doi.org/10.1007/s12649-019-00824-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00824-5