Abstract

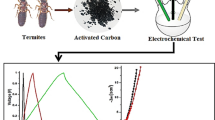

Activated carbons have been obtained from the following organic precursors (lignocellulosic waste materials): willow, rapeseed straw, hemp shives, flax shives, switch grass, Virginia mallow and giant miscanthus. The activation process has been performed by using potassium hydroxide at 750 °C. Elemental analysis has been performed in order to determine the presence of heteroatoms in the carbon structure. Boehm titration was used to estimate the functional groups of carbon materials. The surface area was characterized using gas adsorption method. All the obtained samples have been used as electrodes for electrochemical capacitors operated in 1 M H2SO4. The electrochemical characterization was carried out using cyclic voltammetry, galvanostatic charge/discharge and electrochemical impedance spectroscopy. All measurements proved that carbon materials obtained from different lignocellulosic wastes are suitable for energy storage applications. Moreover, the content of oxygen groups has great influence on the charge storage mechanism. Excessive oxygen content causes the disruption of surface conjugation of the carbon material.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

This paper discusses the behaviour of charge storage of electrodes made of lignocellulosic wastes. Taking into account reducing cost of activated carbon production, current research is focused on the use of waste materials (willow, rapeseed straw, hemp shives, flax shives, giant miscanthus, switch grass and virginia mallow) for electrochemical capacitor applications. Taking into account that an appropriate modification of carbon material by heteroatoms could enhance the pseudocapacitance effect, the side effect of oxygen in its structure is very often neglected. Regarding the fact that electrochemical capacitors attract a great deal of scientific attention, we do hope that you will find our manuscript an interesting and newsworthy paper to be published in Waste & Biomass Valorization international journal.

Introduction

All organic substance which contains elemental carbon in its molecules may be used as organic precursors for the production of activated carbons (AC). They should be characterized not only by a high content of elemental carbon, but low content of volatile parts and high mechanical and thermal resistance as well as easy accessibility and low price. For this reason, AC precursors currently used on an industrial scale include fossil fuels, peat, wood and coconut shells [1]. Taking into account the reduction of activated carbon production cost, current research is focused on the use of lignocellulosic materials from industry or agriculture, such as biomass, as waste-based carbon material precursors. Biomass is a solid or liquid substance of vegetable, marine organism or animal origin which can be biodegradable and originates from agricultural waste and residues from the industry [2, 3]. The huge number of forms of cellulose-lignin composites produced by nature makes it possible to obtain AC from them with different structures and properties. The uniqueness of lignocellulosic materials lies in the chemical and structural diversity of plant tissue. The advantage of these raw materials is also their availability, the possibility of renewing their resources and obtaining a large mass, low price and biocompatibility with the natural environment [4]. Currently, biomass has a great potential for use in removal of contaminants [5] as well as in energy storage systems [6].

Biomass can be used as precursor for activated carbon production. Lignocellulosic materials are composed of cellulose, lignin (aromatic polymers) and hemicelluloses (carbohydrate polymers). Lignin is a complex phenolic polymer, constituting 20–50% of the typical dry lignocellulose, while hemicelluloses account for approximately 20–35%. The main component of lignocellulose is cellulose. Cellulose is one of the most important natural polymers consisting of a linear chain of D-glucose units. Taking into account that over 70 million tons of lignin are produced as a by-product in pulp and paper industry, the use of this type of material for producing activated carbons is a very good idea. Activated carbon can be produced from numerous sources of lignocellulosic materials, like wood, plum stones, coconut shell or risk husk [6, 7].

The first step of AC production is the carbonization process in an inert atmosphere. Carbonization is the thermal decomposition resulting in the elimination of non-carbon species in order to produce char. The second step is the activation of the char for further improvement of the surface area, pore volume and porosity of the activated carbon. The activation process can be performed by means of physical or chemical methods. Physical activation uses steam or CO2 while chemical activation relies on the use of NaOH, KOH, ZnCl2, FeCl3, H3PO4 or K2CO3 [6,7,8]. Activated carbons (according to their good conductivity, high surface area, microporosity, low cost and availability) are very interesting energy storage materials, especially in electrochemical capacitor (supercapacitors) constructions [9]. Supercapacitors are characterized by high efficiency, excellent cyclability, the ability of fast charge and discharge (which allows to obtain higher power density values compared to batteries). In addition, materials which are used in such systems are characterized by low toxicity. Electrochemical capacitors are power sources which efficiently store and provide energy with the possibility of discharging up to 0 V. On the other hand, these systems are characterized by a large voltage drop under open circuit conditions and low energy density values. The increase in the energy of a capacitor can be achieved by extending the system’s operating voltage or as a result of the increase of capacitance. Electrochemical capacitors are devices which store energy by charging the electric double layer. The charging of the double layer is the electrostatic interaction of the electrolyte ions with the surface of the electrode material. The electrode material should be characterized by electrochemical stability, high conductivity, and a well-developed surface accessible for ions. These systems are able to deliver energy at high power rate [10,11,12]. The increase in the capacitance of the electrochemical capacitor can be achieved by the modification of the carbon material in order to produce a higher content of functional groups [13, 14]. As a result of the redox reactions taking place with the aforementioned functional groups, there is an increase in the capacitance of the system (the so-called pseudocapacitive effect) [15, 16]. The increase in capacitance causes an increase in energy density of the system. The energy density could be increased by designing the electrochemical capacitors in an asymmetric system or by constructing hybrid capacitors with electrodes made of carbon/transition metal oxides composites [17, 18].

The aim of this study was the preparation of the activated carbons from different organic precursor in order to determine the charge storage properties in aqueous solution. The following lignocellulosic materials have been used in this study: willow, rapeseed straw, hemp shives, flax shives, giant miscanthus, switch grass and virginia mallow. Depending on the preparation methods as well as the carbon organic precursors, activated carbons are characterized by various physicochemical properties with well developed surface area. In such a case the specific surface area is very important parameter to construct electrochemical capacitors. In this study, some other aspects of the carbon materials like pore size distribution, electrical conductivity, wettability and surface chemistry were taken into consideration. Based on the same procedure of preparation with different organic precursors authors discussed the impact of the surface functional groups, especially the changes of surface conjugation of the electrode material in the presence of oxygen which is very often neglected. Authors tried to established the capacitance by measuring the behavior of positive and negative electrodes simultaneously in symmetric (two-electrode cell) configuration. This approach is very important, because the differences in the already reported capacitances of biomass-derived electrochemical capacitors can be assigned to the method of testing. It is well known that three-electrode cell gives higher capacitance values in the comparison with two-electrode cell measurements.

Experimental

The lignocellulosic materials were ground with a roller mill and sieved. The crushed plant materials were subjected to carbonization. These processes were carried out in a chamber reactor in oxygen free atmosphere by heating to 600 °C at the temperature rate of 3 °C min−1 and then, storage under stable conditions for 1 h. Carbonizates after grinding were activated with potassium hydroxide at a mass ratio of 1:4 in argon atmosphere at 750 °C for 15 min in a nonporous ceramic reactor. Activated carbons (AC) were extracted with 1% hydrochloric acid and then, with deionized water to the neutral pH.

Surface oxygen groups were determined according to the Boehm’s method [19]. A 0.25 g sample of each activated carbon was placed in a 250 ml flask. After adding 25 ml of 0.1 M solution of NaOH, NaHCO3 and0.05 M solution of Na2CO3 (for determination of acidic groups) or 0.1 M HCl (for determination of basic groups), the mixtures were shaken for 24 h. After filtering the mixtures, 10 mL of each filtrate was pipetted and the excess of base and acid was titrated (Tashiro indicator) by 0.1 M solution of HCl or NaOH, respectively. All experiments were repeated twice. The numbers of acidic sites of various types were calculated under the assumption that NaOH neutralizes carboxyl, phenolic and lactonic; Na2CO3—carboxyl and lactonic; and NaHCO3 only carboxyl groups. The number of surface basic sites was calculated from the amount of HCl which reacted with carbon.

The thermal analysis of the activated carbons was carried out on PerkinElmer thermogravimetric analyser using the following conditions: final temperature of 900 °C, rate of temperature increase of 5 °C min−1, atmosphere—helium flowing at the rate of approx. 2 dm3 h−1. The surface area and pore size distribution were obtained by analysis of nitrogen adsorption method at 77K (Micromeritics ASAP 2020 volumetric adsorption system). The elemental analysis was conducted using VARIO MICRO CUBE system.

All the obtained samples were used as electrode materials of an electrochemical capacitor. The electrochemical measurements were carried out using cyclic voltammetry, galvanostatic charge/discharge and electrochemical impedance spectroscopy (potentiostat/galvanostat VMP3, Bio-Logic). All electrochemical studies were carried out with two- and three-electrode cells assembled in a Swagelok® system in 1 M H2SO4. The electrode was composed of 85 wt% of carbon, 10 wt% of PTFE and 5 wt% of acetylene black. The samples and their abbreviations used in this manuscript were presented in Table 1. The conductivity of the prepared electrodes was determined by electrochemical impedance spectroscopy at 1 kHz. As prepared electrodes were subjected to measure the water contact angle on the goniometer. Water drops were placed on the surface of the sample by using a Hamilton micro-syringe (4 µl).

Results and Discussion

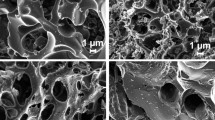

All lignocellulosic materials were subjected to carbonization and activation process. The KOH activation is a very complex reaction between carbon and potassium hydroxide. Three main mechanisms can be distinguished during activation: (a) etching the carbon framework by different potassium compounds, (b) physical activation of carbon by water and carbon dioxide formed during this process and (c) intercalation of metallic potassium into the carbon lattices [20, 21]. After the removal of metallic potassium by washing, high microporosity and surface area are obtained. The results of BET surface area measurements were summarized in the Table 2. It should be noted that the same process of carbonization and activation leads to the production of different activated carbons depending on the lignocellulosic material. The highest surface area was obtained for AC-W sample, however the AC-S sample was characterised by the lowest value of surface area. All obtained isotherms (Fig. 1a, Fig. S1a) represent Type Ib according to the IUPAC classification of adsorption [22]. This type of isotherms are obtained for microporous materials with a small number of narrow mesopores. This type of isotherm tends to be concave to the p/po axis. The presence of micropores of molecular dimensions causes significant nitrogen uptake at low p/po. The pore size distribution of activated carbons (PSD, calculated by NLDFT method with heterogeneous surface model using SAIEUS program, ver. 1.02, by J. Jagiello) [23] confirmed the highest contribution of micropores (Figs. 1b, S1b). Based on the obtained result, the highest content of micropores was detected in the case of AC-W and AC-V samples, therefore their surface area reached the highest value.

Elemental analysis (Table 3) proved that all obtained materials were characterized by abundance of heteroatoms after activation process. All samples were rich in oxygen which could be present in various oxygen functional groups on the carbon surface. Activated carbons obtained from willow (AC-W) and rapeseed straw (AC-R) were characterized by the highest content of sulphur. Moreover, the highest content of nitrogen was found in Virginia mallow-based carbon. It should be noted that the presence of different functional groups in the carbon structure is crucial to construct electrodes for electrochemical capacitors. Therefore, for this purpose, the Boehm titration was applied to determine which types of oxygen functional groups occupy the carbon surface (Table 4). This measurement showed that all obtained samples were rich in acidic as well as basic sites. The concentration of basic moieties decreased with increasing acidic character of the surface. The acidic character is caused by carboxyl groups, lactones and phenolic structure (hydroxyl groups). On the other hand, the basic character can be associated with the presence of pironic, chromenic and π electrons in graphene plane. The highest content of basic sites was measured for AC-R and AC-V samples. It should be noted that quinone/hydroquinone-like structures could participate in electrochemical reaction occurring at the electrolyte/electrode interface. Moreover, thermogravimetric analysis (Figs. 2, S2) confirmed the presence of different functional groups. The surface functionalization was determined by TGA under helium flow. The lowest value of mass loss was reported for AC-W sample. This activated carbon obtained from willow was the most thermally stable due to the lowest content of oxygen in its structure (Fig. 2a). TGA measurements provided not only data regarding thermal stability (mass loss) but also thermal information about functional groups present on the carbon surface. The changes of TGA curve were smooth, therefore a deep analysis could be conducted by its first derivative, namely DTG curve (Fig. 2b). The inflection points in the DTG curve were assigned to decomposition of surface functional groups accompanied by the release of CO or CO2. The first peak between 25 and 150 °C is associated with the elimination of water. It can be assumed that the carbon materials obtained from lignocellulosic wastes are hydrophilic. Moreover, the mass loss between 200 and 500 °C is associated with carbon dioxide release. Carbon dioxide is released mainly after the decomposition of carboxylic groups. Further mass loss (at higher temperature) can be associated with carbon monoxide formation. Carbon monoxide is formed as a result of carboxylic anhydrides, ether-type oxygen, quinone and carbonyl groups [24,25,26,27,28].

It should be noted that heteroatom functionalities could be responsible for increasing the overall capacitance of electrochemical capacitors. In such a case, a pseudocapacitive effect is expected in an acidic medium. Therefore all electrochemical measurements were conducted in a 1 M H2SO4 solution. Cyclic voltammetry conducted in two- and three-electrode cell resulted in an almost rectangular shape (Fig. 3a, b) which proved good capacitive properties of all the obtained samples. The best performance was exhibited by the electrochemical capacitor based on the electrodes made from Switch grass (AC-S) and its voltammograms were presented in the Fig. 1. Calculated capacitances were summarized in Tables 5 and 6. Based on the CV measurements, it can be stated that the highest capacitance was reached by samples AC-S and AC-W. The carbon materials produced from willow (AC-W) was characterized by the highest surface area (1220 m2 g−1), on the other hand activated carbon obtained from switch grass (AC-S) possessed the lowest value of surface area (888 m2 g−1) (Table 2). Despite the fact that this material has a low surface area, the electrochemical capacitor based on this material was characterized by the highest capacitance (228 F g−1). Moreover, activated carbon obtained from willow and switch grass possessed the lowest content of basic sites. It can be stated that quinone/hydroquinone redox couple were responsible for the highest capacitance value in the acidic medium. The overall capacitance was an effect of the electrostatic attraction (charging/discharging electric double layer) as well as pseudocapacitance effect. Moreover, in all cases the negative electrode was characterized by higher capacitance in the comparison with the positive one, which is very important for the construction of systems with asymmetric electrodes (Table 6). It should be noted that the lowest capacitance was observed for AC-R and A-V samples. This type of material was characterized by the highest content of basic sites which are not able to conduct electrochemical reactions responsible for the pseudocapacitive effect. Moreover, the A-V sample is characterized by the highest content of oxygen in its structure. Taking the relatively low surface area and high content of oxygen of the AC-F sample into account, the electrochemical capacitors based on this carbon material reached 210 F g−1. The oxygen functionalities increased the hydrophilic character of this material (the highest mass loss, Fig. S2) and thus the wettability of the electrode in an aqueous electrolyte. It should be noted that the water contact angle measurements in all investigated samples is lower than 90°, which proved the hydrophilic character of electrodes (Table 2). Moreover, electrochemical capacitors based on the AC-S and AC-W samples are characterized by the highest value of conductivity which proved their relatively high capacitance (Table 2).

In the case of the carbon materials rich in heteroatom functionalities, charge storage in the electrode involves Faradaic reactions in a wide potential range (pseudocapacitive effect). Oxygen functionalities can contribute to the pseudocapacitive effect in an appropriate concentration involving electron transfer reaction. Taking into account that oxygen functional groups are connected to conjugated graphene layers, the electrons transferred into (or from) these groups are delocalized. As a result, the constant current flow is responsible for the rectangular shape of cyclic voltammogram (triangular shape of galvanostatic charge/discharge) and it does not present significant current peaks. Moreover, excessive oxygen content causes the changes of surface conjugation of the electrode material. This is due to probably by the increasing sp3 sites in its structure. It should be noted, that despite the relatively high surface area, the AC-V sample is characterized by the lowest capacitance. This sample possess he highest content of oxygen (over 20 wt%) and is characterized by the lowest capacitance as well as the conductivity value (Table 2) [29,30,31,32]. The high diversity of carbon materials are connected with their physical properties and the ratio of sp2 to sp3 bonds. Moreover, taking into account the structural ordering of activated carbons due to their high porosity this kind of materials are predominantly amorphous structure. An amorphous carbon could possess any mixture of sp3, sp2 and even sp1 sites. The sp3 sites are characterized by only σ states while the sp2 sites have also π states. The surface functionalization (especially by oxygen functional groups) causes the conversion of sp2 sites sp3 sites. It can be concluded that sp2 configuration is transformed from rings to chains [11, 33, 34].

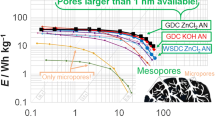

In order to determine the performance of electrochemical capacitors in a more detailed manner, the electrochemical impedance spectroscopy, galvanostatic charge/discharge and cycling stability were also examined. This type of measurements also proved that the best performance was exhibited by the electrochemical capacitor based on the AC-S sample. In all cases (Fig. 4a) the impedance spectra consisted of two parts, the semi-circle at high frequency and the straight line at low frequency region. It should be noted that the lowest value of imaginary part was measured for the AC-S sample. Lower value of the imaginary part of impedance proved the highest capacitance value of such system (237 F g−1 at 1 mHz). In addition, the electrochemical capacitors based on the AC-S sample was characterized by very high charge propagation because its capacitance remained at 206 F g−1 at 10 A g−1 (Fig. 4b). Moreover, all measurements at 2 A g−1 also proved the exceptional stability of this system during 5000 cycles of charge/discharge (Fig. 5a). The capacitance value decreases in this test only from 236 to 224 F g−1. Furthermore, electrochemical capacitors with electrodes made from switch grass were able to deliver energy at a very high power rate which can be seen in the Ragone plot (Fig. 5b). Unfortunately, the energy density was relatively low because it reached 6 Wh kg−1. The energy density can be further increased by appropriate modification of carbon materials or by extending the voltage of this system.

It should be emphasized that depending on the activation method and carbon precursor, activated carbon are characterized by different physicochemical properties and porous structure. Moreover, same other properties (pore size distribution, conductivity, surface functionality, wettability) should be taken into consideration in order to construct electrochemical capacitors [35]. Generally, the higher surface area is, the higher capacitance of supercapacitors is. Sometimes, despite the high specific surface area, some activated carbon are characterized by low capacitance. Apart from the physicochemical properties of activated carbon, this situation can be explained by the different construction of electrochemical capacitor. In such a case, many factors possess a huge impact on the capacitance like: surface chemistry, method of preparing electrodes, the electrolyte used and electrochemical testing method. It should be noted that three-electrode cell measurements resulted in higher capacitance value in the comparison with two-electrode cell. Moreover, despite the same electrochemical method other parameters like: differences in mass loading, electrode thickness, amount of binder, type of current collectors (including corrosion processes [36]) have huge impact on the capacitance value. For example, activated carbons activated in KOH with comparable surface area like sunflower seed shell exhibited 144 F g−1 (10 A g−1, two-electrode cell, 30wt.% KOH as electrolyte) on the other hand water hyacinth reached 273 F g−1 (1 A g−1, three-electrode cell, 6M KOH as electrolyte) [37]. One of the most often used agent for activation is KOH. Depending on the construction of electrochemical capacitors, the capacitances value can easily exceed 200 F g−1 [38,39,40,41]. Activated carbon can be also produced by activation based on the K2CO3. The capacitance values of such prepared materials (based on the waste skins of banana, grapefruit, mandarin and pomelo) vary from 98 to 131 F g−1 (10 mV s−1, 6 M KOH as electrolyte) [8]. It should be noted that promising procedure is to obtain the activated carbon in one-step carbonization without activation. This method was proposed by Juan Du et al. [42]. In this case the non-activated porous carbon displayed high specific capacitance 228.9 F g−1 at 0.5 A g−1 (three-electrode cell in 6 M KOH solution as electrolyte).

Conclusions

The presented study shows that all the obtained materials are desirable and suitable for the construction of electrochemical capacitors. All materials, after being carbonized and activated, are rich in heteroatoms functional groups. The overall capacitance is due to the electrostatic attraction (charging/discharging electric double layer) as well as pseudocapacitance effect. All capacitors based on the obtained samples are characterized by very high capacitance (more than 200 F g−1), very high charge propagation and cycling stability. It should be noted that the highest capacitance was reached in case of the capacitor based on the AC-W sample, which is characterized by the highest surface area, and the AC-S sample, which is characterized by the lowest surface area. High capacitance value resulted in the pseudocapacitance effect at the electrode/electrolyte interface. Moreover, the negative electrode was characterized by the highest capacitance in the comparison with positive one. The lowest capacitance value was detected in the case of the electrochemical capacitor based on the AC-V sample (the highest content of oxygen). Excessive oxygen content causes the disruption of surface conjugation of the carbon material. Moreover, the correlation between physicochemical and electrochemical properties should be always taken into consideration. All of the capacitance values require to be standardized during testing, because not only electrode material influences the performance of the system but also the construction of electrochemical capacitor and testing method.

References

Olowoyo, D.N., Orere, E.E.: Preparation and characterization of activated carbon made from palm-kernel shell, coconut shell, groundnut shell and obeche wood (investigation of apparent density, total ash content, moisture content, particle size distribution parameters). Int. J. Res. Chem. Environ. 2, 32–35 (2012)

Nor, N.M., Lau, L.C., Lee, K.T., Mohamed, A.R.: Synthesis of activated carbon from lignocellulosic biomass and its application in air pollution control—a review. J. Environ. Chem. Eng. 1, 658–666 (2013)

Gonzalez, J.F., Roman, S., Encinar, J.M., Martinez, G.: Pyrolysis of various biomass residues and char utilization for the production of activated carbons. J. Anal. Appl. Pyrolysis 85, 134–141 (2009)

Yahya, M.A., Al-Qodah, Z., Zanariah Ngah, C.W.Z.: Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: a review. Renew. Sustain. Energy Rev. 46, 218–235 (2015)

Chowdhury, Z.Z., Hamid, S.B., Das, R., Hasan, Md.R., Mohd. Zain, S., Khalid, K., Uddin M.N.: Preparation of carbonaceus adsorbents from lignocellulosic biomass and their use in removal of contaminants from aqueous solution. BioResources 8, 6523–6555 (2015)

Lu, H., Zhao, X.,S.: Biomass-derived carbon electrode materials for supercapacitors. Sustain. Energy Fuels 1, 1265–1281 (2017)

Fengel, D., Wegener, G.: Wood-Chemistry, Ultrastructure, Reactions. Walter de Gruyter, Berlin (1989)

Wasiński, K., Nowicki, P., Półrolniczak, P., Walkowiak, M., Pietrzak, R.: Processing organic waste towards high performance carbon electrodes for electrochemical capacitors. Int. J. Electrochem. Sci. 12, 128–143 (2017)

Frackowiak, E., Béguin, F.: Carbon materials for the electrochemical storage of energy in capacitors. Carbon 39, 937–950 (2001)

Kötz, R., Carlen, M.: Principles and applications of electrochemical capacitors. Electrochim. Acta 45, 2483–2498 (2000)

Lota, G., Krawczyk, P., Lota, K., Sierczyńska, A., Kolanowski, Ł, Baraniak, M., Buchwald, T.: The application of activated carbon modified by ozone treatment for energy storage. J. Solid State Electrochem. 20, 2857–2864 (2016)

Lota, G., Tyczkowski, J., Makowski, P., Balcerzak, J., Lota, K., Acznik, I., Pęziak-Kowalska, D., Kolanowski, Ł: The modified activated carbon treated with a low-temperature iodine plasma used as electrode material for electrochemical capacitors. Mater. Lett. 175, 96–100 (2016)

Wang, G., Zhang, L., Zhang, J.: A review of electrode materials for electrochemical supercapacitors. Chem. Soc. Rev. 41, 797–828 (2012)

Inagaki, M., Konno, H., Tanaike, O.: Carbon materials for electrochemical capacitors. J. Power Sources 195, 7880–7903 (2010)

Zhao, Y., Liu, M., Deng, X., Miao, L., Tripathi, P.K., Ma, X., Zhu, D., Xu, Z., Hao, Z., Gan, L.: Nitrogen-functionalized microporous carbon nanoparticles for high performance supercapacitor electrode. Electrochim. Acta 153, 448–455 (2015)

Zhu, D., Wang, Y., Gan, L., Liu, M., Cheng, K., Zhao, Y., Deng, X., Sun, D.: Nitrogen-containing carbon microspheres for supercapacitor electrodes. Electrochim. Acta 158, 166–174 (2015)

Brousse, T., Taberna, P.L., Crosnier, O., Dugas, R., Guillemet, P., Scudeller, Y., Zhou, Y., Favier, F., Bélanger, D., Simon, P.: Long-term cycling behavior of asymmetric activated carbon/MnO2 aqueous electrochemical supercapacitor. J. Power Sources 173, 633–641 (2007)

Bélanger, D., Brousse, T., Long, J.W.: Manganese oxides: Battery materials make the leap to electrochemical capacitors. Electrochem. Soc. Interface 17, 49–52 (2008)

Boehm, H.P.: Some aspects of the surface chemistry of carbon blacks and other carbons. Carbon 32, 759–769 (1994)

Abechi, S.E., Gimba, C.E., Uzairu, A., Dallatu, Y.A.: Preparation and characterization of activated carbon from palm kernel shell by chemical activation. Res. J. Chem. Sci. 3, 54–61 (2013)

Wang, J., Kaskel, S.: KOH activation of carbon-based materials for energy storage. J. Mater. Chem. 22, 23710–23725 (2012)

Thommes, M., Kaneko, K., Neimark, A.V., Olivier, J.P., Rodriguez-Reinoso, F., Rouquerol, J., Sing, K.S.W.: Physisorption of gases, with special reference to the evaluation of surface and pore size distribution (IUPAC technical report). Pure Appl. Chem. 87, 1051–1069 (2015)

Jagiello, J., Olivier, J.P.: 2D-NLDFT adsorption models for carbon slit-shaped pores with surface energetical heterogeneity and geometrical corrugation. Carbon 55, 70–80 (2013)

Liang, S., Li, G., Tian, R.: Multi-walled carbon nanotubes functionalized with a ultrahigh fraction of carboxyl and hydroxyl groups by ultrasound-assisted oxidation. J. Mater. Sci. 51, 3513–3524 (2016)

Gościanska, J., Olejnik, A., Nowak, I., Marciniak, M., Pietrzak, R.: Stability analysis of functionalized mesoporous carbon materials in aqueous solution. Chem. Eng. J. 290, 209–219 (2016)

Biniak, S., Szymański, G., Siedlewski, J., Świątkowski, A.: The characterization, of activated carbons with oxygen and nitrogen surface groups. Carbon 35, 1799–1810 (1997)

Szymański, G., Karpiński, Z., Biniak, S., Świątkowski, A.: The effect of the gradual thermal decomposition of surface oxygen species on the chemical and catalytic properties of oxidized activated carbon. Carbon 40, 2627–2639 (2002)

Boehm, H.,P.: Surface oxides on carbon and their analysis: a critical assessment. Carbon 40, 145–149 (2002)

Chen, G.Z.: Understanding supercapacitors based on nano-hybrid materials with interfacial conjugation. Prog. Nat. Sci. Mater. Int. 23, 245–255 (2013)

Dryfe, R., Chen, G.,Z., Bayer, D., Jonsson-Niedziolka, M., McCreery, R., Macpherson, J., Abruna, H., Gogotsi, Y., Hu, C.,-C., Béguin, F., Hardwick, L., Foord, J., Duca, M., Howe, E., Holt, K., Alvarez-Guerra, M., Unwin, P.,R., Rabbow, T., Shaffer, M., Lee, J.,-S., Frackowiak, E., Qiu, F., Dyatkin, B., Ash, P.,A., Stevenson, K., Guldi, D., Bergonzo, P.: The many faces of carbon in electrochemistry: general discussion. Faraday Discuss. 172, 117–137 (2014)

Guan, L., Yu, L., Chen, G.,Z.: Capacitive and non-capacitive faradaic charge storage. Electrochim. Acta 206, 464–478 (2016)

Yu, L., Chen, G.,Z.: Redox electrode materials for supercapatteries. J. Power Sources 326, 604–612 (2016)

Ferrari, A.,C., Robertson, J.: Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 61, 14095–14107 (2000)

Omri, A., Benzina, M.: Characterization of activated carbon prepared from a new raw lignocellulosic material: Ziziphus spina-christi seeds. J. Soc. Chim. Tunis. 14, 175–183 (2012)

Zhang, L.,L., Zhao, X.,S.: Carbon-based materials as supercapacitor electrodes. Chem. Soc. Rev. 38, 2520–2531 (2009)

Wojciechowski, J., Kolanowski, Ł, Bund, A., Lota, G.: The influence of current collector corrosion on the performance of electrochemical capacitors. J. Power Sources 368, 18–29 (2017)

Enock, T.,K., King, C.K., Pogrebnoi, A., Abeid, Y., Chande, C.: Status of biomass derived carbon materials for supercapacitor application. Int. J. Electrochem. 2017, 1–14 (2017)

Momodu, D., Madito, M., Barzegar, F., Bello, A., Khaleed, A., Olaniyan, O., Dangbegnon, J., Manyala, N.: Activated carbon derived from tree bark biomass with promising material properties for supercapacitors. J. Solid State Electrochem. 21, 859–872 (2017)

Balathanigaimani, M.,S., Shim, W., Kim, S.C.: Biomass-based carbon materials for energy storage and environmental applications. Appl. Chem. Eng. 28, 8–16 (2017)

Liang, T., Chen, C., Li, X., Zhang, J.: Popcorn-derived porous carbon for energy storage and CO2 capture. Langmuir 32, 8042–8049 (2016)

Zhang, G., Chen, Y., Chen, Y., Guo, H.: Activated carbon made from bamboo as electrode material for supercapacitor. Mater. Res. Bull. 102, 391–398 (2018)

Du, J., Yu, Y., Lv, H., Chen, C., Zhang, J., Chen, A.: Cauliflower-derived porous carbon without activation for electrochemical capacitor and CO2 capture applications. J. Nanopart. Res. 20, 1–12 (2018)

Acknowledgements

This work was financially supported by the National Science Centre of Poland (Project No. DEC-2013/10/E/ST5/00719).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kolanowski, Ł., Graś, M., Bartkowiak, M. et al. Electrochemical Capacitors Based on Electrodes Made of Lignocellulosic Waste Materials. Waste Biomass Valor 11, 3863–3871 (2020). https://doi.org/10.1007/s12649-019-00598-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00598-w