Abstract

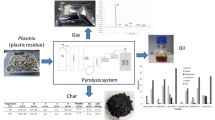

Advanced carbon material production via pyrolysis is an economical process for the recycling-utilization of waste plastics. The purpose of this study is to demonstrate the characteristics and formation mechanism of nano-scale soot particles from waste plastic pyrolysis at high temperatures. Waste rigid polyurethane (PU) was adopted to decompose in an entrained flow reactor at 1000, 1100, 1200, and 1300 °C. The yield, morphology, elemental composition, chemical and crystal structure, and reactivity of soot particles, and the yield and composition of gas products were measured and characterized. Results show that with the temperature increasing from 1000 to 1200 °C, the soot yield increases from 12.2 to 26.5 wt%, while with the temperature increasing to 1300 °C, the change on soot yield is slight. The morphology analysis by scanning transmission electron microscopy indicates that the inception of soot particles starts at 1100 °C, when the onion layered structure of spherical particles (20–50 nm) is observed. With increased temperature, the soot particle size becomes smaller and more uniform. Fourier transform infrared analysis and X-ray diffraction characterization present more C=C functional groups and better graphite structures at higher temperatures, agreeing with the increased carbon content in soot. The oxidation reactivity of soot particles generally increased with the increase of pyrolysis temperature. NaCl is observed in soot particles when the pyrolysis temperature is higher than 1100 °C, as an efficient catalyst, significantly enhances the ignition and burnout of soot particles. The soot formation pathway during plastic pyrolysis is finally proposed based on the measurement of representative gases.

Similar content being viewed by others

References

Li, C.-T., Lee, W.-J., Mi, H.-H., Su, C.-C.: PAH emission from the incineration of waste oily sludge and PE plastic mixtures. Sci. Total Environ. 170(3), 171–183 (1995)

Rochman, C.M., Browne, M.A., Halpern, B.S., Hentschel, B.T., Hoh, E., Karapanagioti, H.K., Rios-Mendoza, L.M., Takada, H., Teh, S., Thompson, R.C.: Policy: classify plastic waste as hazardous. Nature 494(7436), 169–171 (2013)

Ma, W., Hoffmann, G., Schirmer, M., Chen, G., Rotter, V.S.: Chlorine characterization and thermal behavior in MSW and RDF. J. Hazard. Mater. 178(1), 489–498 (2010)

Zhang, H., Xiao, R., Nie, J., Jin, B., Shao, S., Xiao, G.: Catalytic pyrolysis of black-liquor lignin by co-feeding with different plastics in a fluidized bed reactor. Bioresour. Technol. 192, 68–74 (2015)

Kaminsky, W., Kim, J.-S.: Pyrolysis of mixed plastics into aromatics. J. Anal. Appl. Pyrolysis 51(1), 127–134 (1999)

Kaminsky, W., Mennerich, C.: Pyrolysis of synthetic tire rubber in a fluidised-bed reactor to yield 1, 3-butadiene, styrene and carbon black. J. Anal. Appl. Pyrolysis 58, 803–811 (2001)

Walendziewski, J.: Continuous flow cracking of waste plastics. Fuel Process. Technol. 86(12), 1265–1278 (2005)

Zhou, D., Xing, L.: Process of producing gasoline, diesel and carbon black with waste rubbers and/or waste plastics. Google Patents (1998)

Miskolczi, N., Angyal, A., Bartha, L., Valkai, I.: Fuels by pyrolysis of waste plastics from agricultural and packaging sectors in a pilot scale reactor. Fuel Process. Technol. 90(7), 1032–1040 (2009)

Pol, V.G.: Upcycling: converting waste plastics into paramagnetic, conducting, solid, pure carbon microspheres. Environ. Sci. Technol. 44(12), 4753–4759 (2010)

Roy, C., Labrecque, B., de Caumia, B.: Recycling of scrap tires to oil and carbon black by vacuum pyrolysis. Resour. Conserv. Recycl. 4(3), 203–213 (1990)

Roy, C., Chaala, A., Darmstadt, H.: The vacuum pyrolysis of used tires: end-uses for oil and carbon black products. J. Anal. Appl. Pyrolysis 51(1), 201–221 (1999)

Markstein, G.: Radiative properties of plastics fires. In: Symposium (International) on Combustion, vol. 1, pp. 1053–1062. Elsevier (1979)

Gu, M., Chu, H., Liu, F.: Effects of simultaneous hydrogen enrichment and carbon dioxide dilution of fuel on soot formation in an axisymmetric coflow laminar ethylene/air diffusion flame. Combust. Flame 166, 216–228 (2016)

Wheatley, L., Levendis, Y.A., Vouros, P.: Exploratory study on the combustion and PAH emissions of selected municipal waste plastics. Environ. Sci. Technol. 27(13), 2885–2895 (1993)

Shemwell, B.E., Levendis, Y.A.: Particulates generated from combustion of polymers (plastics). J. Air Waste Manag. Assoc. 50(1), 94–102 (2000)

Panagiotou, T., Levendis, Y.A., Carlson, J., Dunayevskiy, Y.M., Vouros, P.: Aromatic hydrocarbon emissions from burning poly (styrene), poly (ethylene) and PVC particles at high temperatures. Combust. Sci. Technol. 116(1–6), 91–128 (1996)

You, J.-H., Chiang, P.-C., Chang, K.-T., Chang, S.-C.: Polycyclic aromatic hydrocarbons (PAHs) and mutagenicity of soot particulates in air emissions from two-stage incineration of polystyrene. J. Hazard. Mater. 36(1), 1–17 (1994)

Wang, J., Richter, H., Howard, J.B., Levendis, Y.A., Carlson, J.: Polynuclear aromatic hydrocarbon and particulate emissions from two-stage combustion of polystyrene: the effects of the secondary furnace (afterburner) temperature and soot filtration. Environ. Sci. Technol. 36(4), 797–808 (2002)

Wang, Z., Richter, H., Howard, J.B., Jordan, J., Carlson, J., Levendis, Y.A.: Laboratory investigation of the products of the incomplete combustion of waste plastics and techniques for their minimization. Ind. Eng. Chem. Res. 43(12), 2873–2886 (2004)

Qin, K., Lin, W., Fæster, S., Jensen, P.A., Wu, H., Jensen, A.D.: Characterization of residual particulates from biomass entrained flow gasification. Energy Fuels 27(1), 262–270 (2012)

Wang, X., Li, S., Adeosun, A., Li, Y., Vujanović, M., Tan, H., Duić, N.: Effect of potassium-doping and oxygen concentration on soot oxidation in O2/CO2 atmosphere: a kinetics study by thermogravimetric analysis. Energy Convers. Manag. 149(1), 686–697 (2017)

Jiao, L., Xiao, H., Wang, Q., Sun, J.: Thermal degradation characteristics of rigid polyurethane foam and the volatile products analysis with TG-FTIR-MS. Polym. Degrad. Stab. 98(12), 2687–2696 (2013)

He, J.-J., Jiang, L., Sun, J.-H., Lo, S.: Thermal degradation study of pure rigid polyurethane in oxidative and non-oxidative atmospheres. J. Anal. Appl. Pyrol. 120, 269–283 (2016)

Jomaa, G., Goblet, P., Coquelet, C., Morlot, V.: Kinetic modeling of polyurethane pyrolysis using non-isothermal thermogravimetric analysis. Thermochim. Acta 612, 10–18 (2015)

Esperanza, M., Font, R., Garcıa, A.: Toxic byproducts from the combustion of varnish wastes based on polyurethane in a laboratory furnace. J. Hazard. Mater. 77(1), 107–121 (2000)

Zhang, Y., Kajitani, S., Ashizawa, M., Miura, K.: Peculiarities of rapid pyrolysis of biomass covering medium-and high-temperature ranges. Energy Fuels 20(6), 2705–2712 (2006)

Zhang, Y., Kajitani, S., Ashizawa, M., Oki, Y.: Tar destruction and coke formation during rapid pyrolysis and gasification of biomass in a drop-tube furnace. Fuel 89(2), 302–309 (2010)

Han, J., Kim, H.: The reduction and control technology of tar during biomass gasification/pyrolysis: an overview. Renew. Sustain. Energy Rev. 12(2), 397–416 (2008)

Daly, H.M., Horn, A.B.: Heterogeneous chemistry of toluene, kerosene and diesel soots. Phys. Chem. Chem. Phys. 11(7), 1069–1076 (2009)

Zolin, A., Jensen, A.D., Jensen, P.A., Dam-Johansen, K.: Experimental study of char thermal deactivation. Fuel 81(8), 1065–1075 (2002)

Zolin, A., Jensen, A., Jensen, P.A., Frandsen, F., Dam-Johansen, K.: The influence of inorganic materials on the thermal deactivation of fuel chars. Energy Fuels 15(5), 1110–1122 (2001)

Septien, S., Valin, S., Dupont, C., Peyrot, M., Salvador, S.: Effect of particle size and temperature on woody biomass fast pyrolysis at high temperature (1000–1400 C). Fuel 97, 202–210 (2012)

Bitowft, B., Andersson, L.A., Bjerle, I.: Fast pyrolysis of sawdust in an entrained flow reactor. Fuel 68(5), 561–566 (1989)

Acknowledgements

The authors gratefully acknowledge the financial support of the National Key Research and Development Plan of China (No. 2016YFB0600605), the National Natural Science Foundation of China (Nos. 51676157 and 5161101654), and the Fundamental Research Funds for the Central Universities. We would also like to thank Prof. Richard L. Axelbaum and Dr. Benjamin Kumfer at Washington University in St. Louis for the valuable discussion on the soot formation mechanism.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Li, Y., Bai, S. et al. Nano-Scale Soot Particle Formation During the High-Temperature Pyrolysis of Waste Plastics in an Entrained Flow Reactor. Waste Biomass Valor 10, 3857–3866 (2019). https://doi.org/10.1007/s12649-018-0322-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0322-x