Abstract

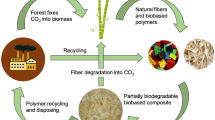

The aim of this work is the valorization of diss fibers with recycled and regenerated low-density polyethylene (rLDPE) for the development of biocomposites based on blends of rLDPE polypropylene (PP) and diss fibers. The diss fibers were characterized by laser granulometer and FTIR spectroscopy. Two PP/rLDPE blends of different compositions (50/50 and 75/25) were prepared. These polymer blends were reinforced by nano-Si particles and compatibilizers which were investigated using three compatibilizers: maleic anhydride functionalized ethylene copolymer rubber (MAC), maleic anhydride functionalized ethylene copolymer rubber/SiO2 (MAC/SiO2), and maleic anhydride functionalized ethylene copolymer rubber/SiO2/ionic liquid (MAC/SiO2/IL). The thermal properties of the blends were studied using differential scanning calorimetry and thermogravimetric analysis. Their crystallinity was investigated by X-ray diffraction and their morphology by scanning electron microscopy, while mechanical properties were evaluated by tensile testing. The best tensile properties were obtained for the PP/rLDPE (75/25) blend. A significant increase of the Young’s modulus, stress at break, and elongation at break was obtained with the three compatibilizers. MAC acted as a compatibilizer of both polymers, resulting in improved interfacial adhesion which increased tensile properties. Finally, the effect of diss fiber surface modification on the properties of PP/rLDPE blends was considered. The results showed a modification of tensile properties and a satisfactory interfacial adhesion between diss fibers and polymer blends. Furthermore, thermal stability was not significantly decreased by the addition of 5 wt% diss fibers.

Similar content being viewed by others

References

Zhao, J., Chen, M., Wang, X., Zhao, X., Wang, Z., Dang, Z.-M., Ma, L., Hu, G.-H., Chen, F.: Triple shape memory effects of cross-linked polyethylene/polypropylene blends with cocontinuous architecture. ACS Appl. Mater. Interfaces 5, 5550–5556 (2013)

Thakur, V.K., Vennerberg, D., Kessler, M.R.: Green aqueous surface modification of polypropylene for novel polymer nanocomposites. ACS Appl. Mater. Interfaces 6, 9349–9356 (2014)

Himma, N.F., Anisah, S., Prasetya, N., Wenten, I.G.: Advances in preparation, modification, and application of polypropylene membrane. J. Polym. Eng. 36, 329–362 (2015)

Pedrazzoli, D., Pegoretti, A.: Silica nanoparticles as coupling agents for polypropylene/glass composites. Compos. Sci. Technol. 76, 77–83 (2013). https://doi.org/10.1016/j.compscitech.2012.12.016

Izzati Zulkifli, N., Samat, N., Anuar, H., Zainuddin, N.: Mechanical properties and failure modes of recycled polypropylene/microcrystalline cellulose composites. Mater. Des. 69, 114–123 (2015). https://doi.org/10.1016/j.matdes.2014.12.053

Maani, A., Naguib, H.E., Heuzey, M.C., Carreau, P.J.: Foaming behavior of microcellular thermoplastic olefin blends. J. Cell. Plast. 49, 223–244 (2013). https://doi.org/10.1177/0021955X13477435

Blom, H.P., Teh, J.W., Rudin, A., PP/PE blends. IV. Characterization and compatibilization of blends of postconsumer resin with virgin PP and HDPE. J. Appl. Polym. Sci. 70, 2081–2095 (1998)

Al-Salem, S.M., Lettieri, P., Baeyens, J.: Recycling and recovery routes of plastic solid waste (PSW): a review. Waste Manag. 29, 2625–2643 (2009). https://doi.org/10.1016/j.wasman.2009.06.004

Mustafa, N.: Plastic Waste Management. Canadian Plastics Institute, Toronto (1993)

John, S.: Polymer Recycling. Wiley, Chichester (1998)

Yu, M., Huang, R., He, C., Wu, Q., Zhao, X.: Hybrid composites from wheat straw, inorganic filler, and recycled polypropylene: morphology and mechanical and thermal expansion performance. Int. J. Polym. Sci. (2016). https://doi.org/10.1155/2016/2520670

Xu, B., Lin, Z., Xian, J., Huo, Z., Cao, L., Wang, Y., Gaosun, W., Mai, K., Wang, Y.: Preparation and characterization of polypropylene composites with nonmetallic materials recycled from printed circuit boards. J. Thermoplast. Compos. Mater. 29, 48–57 (2016). https://doi.org/10.1177/0892705713518788

Salmah, H., Azra, B.N., Yusrina, M.D., Ismail, H.: A comparative study of polypropylene/(chloroprene rubber) and (recycled polypropylene)/(chloroprene rubber) blends. J. Vinyl Addit. Technol. 21, 122–127 (2015). https://doi.org/10.1002/vnl.21390

Garlof, S., Mecklenburg, M., Smazna, D., Mishra, Y.K., Adelung, R., Schulte, K., Fiedler, B.: 3D carbon networks and their polymer composites: fabrication and electromechanical investigations of neat Aerographite and Aerographite-based PNCs under compressive load. Carbon. 111, 103–112 (2017)

Thakur, V.K., Singha, A.S., Thakur, M.K.: In-air graft copolymerization of ethyl acrylate onto natural cellulosic polymers. Int. J. Polym. Anal. Charact. 17, 48–60 (2012)

Parlak, O., Kumar Mishra, Y., Grigoriev, A., Mecklenburg, M., Luo, W., Keene, S., Salleo, A., Schulte, K., Ahuja, R., Adelung, R., Turner, A.P.F., Tiwari, A.: Hierarchical Aerographite nano-microtubular tetrapodal networks based electrodes as lightweight supercapacitor. Nano Energy. 34, 570–577 (2017)

Thakur, V.K., Singha, A.S., Thakur, M.K.: Surface modification of natural polymers to impart low water absorbency. Int. J. Polym. Anal. Charact. 17, 133–143 (2012)

Singha, A.S., Thakur, V.K.: Mechanical, thermal and morphological properties of grewia optiva fiber/polymer matrix composites. Polym. Plast. Technol. Eng. 48, 201–208 (2009). https://doi.org/10.1080/03602550802634550

Sellami, A., Merzoud, M., Amziane, S.: Improvement of mechanical properties of green concrete by treatment of the vegetals fibers. Constr. Build. Mater. 47, 1117–1124 (2013). https://doi.org/10.1016/j.conbuildmat.2013.05.073

Bertin, S., Robin, J.J.: Study and characterization of virgin and recycled LDPE/PP blends. Eur. Polym. J. 38, 2255–2264 (2002)

Shanks, R.A., Li, J., Chen, F., Amarasinghe, G.: Time-temperature-miscibility and morphology of polyolefin blends. Chin. J. Polym. Sci. 18, 263–270 (2000)

Guerfi, N., Belhaneche-Bensemra, N.: Preparation, characterization and valorization of regenerated low density polyethylene/polypropylene blends. Environ. Eng. Manag. J13, 2609–2613 (2014)

Radonjic, G., Gubeljak, N.: The use of ethylene/propylene copolymers as compatibilizers for recycled polyolefin blends. Macromol. Mater. Eng. 287, 1 22–132 (2002)

Vaccaro, E., Dibenedetto, A.T., Huang, S.J.: Yield strength of low-density polyethylene-polypropylene blends. J. Appl. Polym. Sci. 63, 275–281 (1997)

Yang, M.B., Wang, K., Ye, L., Mai, Y.W., Wu, J.S.: Low density polyethylene-polypropylene blends part 2—strengthening and toughening with copolymer. Plast. Rubber Compos. 32, 27–31 (2003)

Elias, L., Fenouillot, F., Majeste, J.C., Cassagnau, P.: Morphology and rheology of immiscible polymer blends filled with silica nanoparticles. Polymer 48, 6029–6040 (2007)

Yang, H., Zhang, X., Qu, C., Li, B., Zhang, L., Zhang, Q.: Largely improved toughness of PP/EPDM blends by adding nano-SiO 2 particles. Polymer 48, 860–869 (2007)

Jose, S., Thomas, S., Biju, P.K., Karger-Kocsis, J.: Mechanical and dynamic mechanical properties of polyolefin blends: effect of blend ratio and copolymer monomer fraction on the compatibilisation efficiency of random copolymers. J. Polym. Res. 20, 303 (2013). https://doi.org/10.1007/s10965-013-0303-5

Safadi, B., Andrews, R., Grulke, E.A.: Multiwalled carbon nanotube polymer composites: synthesis and characterization of thin films J. Appl. Polym. Sci. (2002).https://doi.org/10.1002/app.10436

Thankappan Nair, S., Vijayan, P.P., Xavier, P., Bose, S., George, S.C., Thomas, S.: Selective localisation of multi walled carbon nanotubes in polypropylene/natural rubber blends to reduce the percolation threshold. Compos. Sci. Technol. 116, 9–17 (2015). https://doi.org/10.1016/j.compscitech.2015.04.021

Dorigato, A., Pegoretti, A., Frache, A.: Thermal stability of high density polyethylene–fumed silica nanocomposites. J. Therm. Anal. Calorim. 109, 863–873 (2012). https://doi.org/10.1007/s10973-012-2421-4

Dorigato, A., Pegporetti, A.: Reprocessing effects on propylene/silica nanocomposites. J. Appl. Polym. Sci. (2014). https://doi.org/10.1002/APP.40242

Jeziórska, R., Świerz-Motysia, B., Zielecka, M., Szadkowska, A., Studziński, M.: Structure and mechanical properties of low-density polyethylene/spherical silica nanocomposites prepared by melt mixing: the joint action of silica’s size, functionality, and compatibilizer. J. Appl. Polym. Sci. 125, 4326–4337 (2012). https://doi.org/10.1002/app.36579

Daramola, O.O., Oladele, I.O., Adewuyi, B.O., Sadiku, R., Agwuncha, S.C.: Thermal, structural and morphological properties of high density polyethylene matrix composites reinforced with submicron agro silica particles and Titania particles. J. Taibah Univ. Sci. 11, 645–653 (2017). https://doi.org/10.1016/j.jtusci.2016.08.006

Vladimirov, V., Betchev, C., Vassiliou, A., Papageorgiou, G., Bikiaris, D.: Dynamic mechanical and morphological studies of isotactic polypropylene/fumed silica nanocomposites with enhanced gas barrier properties. Compos. Sci. Technol. 66, 2935–2944 (2006). https://doi.org/10.1016/j.compscitech.2006.02.010

Kurokawa, Y., Yasuda, H., Oya, A.J.: Preparation of a nanocomposite of polypropylene and smectite. J. Mater. Sci. Lett. 15, 1481–1483 (1996)

Ray, S.S., Okamoto, M.: Polymer/layered silicate nanocomposites: a review from preparation., Prog. Polym. Sci. (2003). https://doi.org/10.1016/j.progpolymsci.2003.08.002

Jain, S., Goossens, H., Picchioni, F., Magusin, P., Mezari, B., Van Duin, M.: Synthetic aspects and characterization of polypropylene-silica nanocomposites prepared via solid-state modification and sol-gel reactions. Polymer 46, 6666 (2005)

Jankong, S., Srikulkit, K.: Preparation of polypropylene/hydrophobic silica nanocomposites. J. Met. Mater. Miner. 18, 143–146 (2008)

Kato, M., Usuki, A., Okada, A.: Synthesis of polypropylene oligomer—clay intercalation compounds. J. Appl. Polym. Sci. 66, 1781–1785 (1997)

Livi, S., Duchet-Rumeau, J., Pham, T.N., Gerard, J.F.: A comparative study on different ionic liquids used as surfactants: effect on thermal and mechanical properties of high-density polyethylene nanocomposites. J. Colloid Interface Sci. 349, 424–433 (2010)

Livi, S., Gerard, J.F., Duchet-Rumeau, J.: Ionic liquids: structuration agents in a fluorinated matrix. Chem. Commun. 47, 3589–3591 (2011)

Livi, S., Duchet-Rumeau, J., Pham, T.N., Gerard, J.F.: Synthesis and physical properties of new surfactants based on ionic liquids: improvement of thermal stability and mechanical behaviour of high density polyethylene nanocomposites., J. Colloid Interface Sci. (2011) https://doi.org/10.1016/j.jcis.2010.10.058

Rahman, M., Brazel, C.S.: Ionic liquids: new generation stable plasticizers for poly (vinyl chloride). Polym. Degrad. Stab. 91, 3371–3382 (2006)

Yao, M., Fan, M., Liang, Y., Zhou, F., Xia, Y.: Imidazolium hexafluorophosphat ionic liquids as high temperature lubricants for steel–steel contacts. Wear 268, 67–71 (2010)

Xing, C., Zhao, L., You, J., Dong, W., Cao, X., Li, Y.: Impact of ionic liquid-modified multiwalled carbon nanotubes on the crystallization behavior of poly(vinylidenefluoride). J. Phys. Chem. B 116, 8312–8320 (2012)

Xing, C., Zhao, M., Zhao, L., You, J., Cao, X., Li, Y.: Ionic liquid modified poly(vinylidenefluoride): crystalline structures, miscibility, and physical properties. Polym. Chem. 4, 5726–5734 (2013)

Zhao, L., Li, Y., Cao, X., You, J., Dong, W.: Multifunctional role of an ionic liquid in melt-blended poly (methyl methacrylate)/multi-walled carbon nanotube nanocomposites. Nanotechnology (2012). https://doi.org/10.1088/0957-4484/23/25/255702

Leroy, E., Jacquet, P., Coativy, G., Reguerre, A.L., Lourdin, D.: Compatibilization of starch–zein melt processed blends by an ionic liquid used as plasticizer. Carbohydr. Polym. 89, 955–963 (2012)

Marinelli, A.L., Bretas, R.E.S.: Blends of polypropylene resins with a liquid crystalline polymer. I. Isothermal crystallization., J. Appl. Polym. Sci. (2003). https://doi.org/10.1002/app.11386

Hung, K.-C., Wu, T.-L., Chen, Y.-L., Wu, J.-H.: Assessing the effect of wood acetylation on mechanical properties and extended creep behavior of wood/recycled-polypropylene composites. Constr. Build. Mater. 108, 139–145 (2016)

Bessadok, A., Marais, S., Roudesli, S., Lixon, C., Métayer, M.: Influence of chemical modifications on water-sorption and mechanical properties of Agave fibres. Compos. A 39, 29–45 (2008)

Hejun, W., Mei, L., Canhui, L.: Non-isothermal crystallization kinetics of peroxide-crosslinked polyethylene: effect of solid state mechanochemical milling. Thermochim. Acta (2012). https://doi.org/10.1016/j.tca.2012.07.008

Zhao, J., Chen, M., Wang, X., Zhao, X., Wang, Z., Dang, Z.M., Ma, L., Hu, G.H., Chen, F.: Triple shape memory effects of cross-linked polyethylene/polypropylene blends with cocontinuous architecture. ACS Appl. Mater. Interfaces (2013). https://doi.org/10.1021/am400769j

Gui, Z., Wang, H., Gao, Y., et al.: Morphology and melt rheology of biodegradable poly(lactic acid)/poly(butylenes succinate adipate) blends: effect of blend composition. Iran. Polym. J. 21, 81–89 (2012)

Olsson, A.M., Salmén, L.: The association of water to cellulose and hemicellulose in paper examined by FTIR spectroscopy. Carbohydr. Res. (2004). https://doi.org/10.1016/j.carres.2004.01.005

Garside, P., Wyeth, P.: Identification of cellulosic fibres by FTIR spectroscopy: thread and single fibre analysis by attenuated total reflectance. Stud. Conserv. 48(4), 269–275 (2003)

Garside, P., Wyeth, P.: Identification of cellulosic fibres by FTIR spectroscopy: thread and single fibre analysis by attenuated total reflectance. Stud Conserv. 48, 269–275 (2006)

Bessadok, A., Marais, S., Gouanve, F., Colasse, L., Zimmerlin, I., Roudesli, S., et al.: Effect of chemical treatments of Alfa (Stipa tenacissima) fibres on water-sorption properties. Compos. Sci. Technol. (2006). https://doi.org/10.1016/j.compscitech.2006.04.013

Sreekumar, P.A., Saiah, R., Saiter, J.M., Leblanc, N., Joseph, K., Unnikrishnan, G., et al.: Thermal behaviour of treated and untreated sisal fiber reinforced polyester composites fabricated by resin transfer moulding. Compos. Interfaces 15, 629–650 (2008)

Shi, X., Gan, Z.: Preparation and characterization of poly (propylene carbonate)/montmorillonite nanocomposites by solution intercalation. Eur. Polym. J. 43, 4852–4858 (2007)

Reza Dadfar, S.M., Ahmad Ramazani, S.A., Ali Dadfar, S.M.: Investigation of oxygen barrier properties of organoclay/HDPE/EVA nanocomposite films prepared using a two-step solution method. Polym. Compos. (2008). https://doi.org/10.1002/pc.20711

Santos, K., Bischoff, E., Liberman, S., Oviedo, M., Mauler, R.: The effects of ultrasound on organoclay dispersion in the PP matrix. Ultrason. Sonochem. 18, 997–1001 (2011)

Kim, N.H., Malhotra, S.V., Xanthos, M.: Modification of cationic nanoclays with ionic liquids. Microporous Mesoporous Mater. 96, 29–35 (2006)

Awad, W.H., Gilman, J.W., Nyden, M., Harris, R.H., Sutto, T.E., Callahan, J., Trulove, P.C., DeLong, H.C., Fox, D.M.: Thermal degradation studies of alkylimidazolium salts and their application in nanocomposites. Thermochim. Acta 409, 3–11 (2004)

Awad, W.H., Gilman, J.W., Nyden, M., Davis, R., Harris, R.H., Sutto, T.E., Callahan, J.H., Delong, H.C., Trulove, P.C.: Thermal degradation studies of alkyl imidazolium salts and their application in nanocomposites. Molten Salts 13, 200–212 (2002)

Xie, W., Xie, R.C., Pan, W.P., Hunter, D., Koene, B., Tan, L.S., Vaia, R.: Thermal stability of quaternary phosphonium modified montmorillonites. Chem. Mater. 14, 4837–4845 (2002)

Byrne, C., McNally, T.: Ionic liquid modification of layered silicates for enhanced thermal stability. Macromol. Rapid Commun. 28, 780–784 (2007)

Rizzo, P., Baione, F., Guerra, G., Martinotto, L., Albizzati, E.: Polyethylene unit cell and crystallinity variations as a consequence of different cross-linking processes. Macromolecules 34, 5175–5179 (2001)

Song, P., Cao, Z., Cai, Y., Zhao, L., Fang, Z., Fu, S.: Fabrication of exfoliated grapheme based polypropylene nanocomposites with enhanced mechanical and thermal properties. Polymer (2011). https://doi.org/10.1016/j.polymer.2011.06.045

Funding

The funding was provided by Direction Générale de la Recherche Scientifique et du Développement Technologique.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Touati, Z., Boulahia, H., Belhaneche-Bensemra, N. et al. Modification of Diss Fibers for Biocomposites Based on Recycled Low-Density Polyethylene and Polypropylene Blends. Waste Biomass Valor 10, 2365–2378 (2019). https://doi.org/10.1007/s12649-018-0225-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0225-x