Abstract

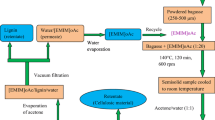

This work aims to evaluate the recovery of soluble lignin from an effluent produced in the alkaline delignification of sugarcane bagasse. The lignin polymerization was carried out using different substract-enzyme relation, namely 0.05 and 1.8 mg soluble lignin for peroxidase activity, and different H2O2 concentration, namely 0.18 and 2.1 mol of H2O2 per peroxidase unit, furthermore was achieved using horseradish peroxidase and a preliminary study using laccase produced by Trametes versicolor. The highest lignin polymerization yield was 93 % for 50 μg lignin/unit of peroxidase activity and 0.2 μmol of H2O2/unit of peroxidase activity. The polymerization process occurred after a considerable increase in the molecular weight of lignin (from 415 Da in the effluent to 2,122 Da in the polymer obtained after 30 min of reaction) as demonstrated by gel permeation chromatography. The average molecular weight of the obtained polymer changed as a function of reaction time, which of 0, 0.5, 4.0, 8.0, 16.0 and 42.0 h produced lignin polymers with 415, 2,122, 1,576, 1,150, 794 and 4,595 Da, respectively. The preliminary treatment study of the effluent with a culture broth of T. versicolor with laccase increased the average molecular weight of soluble lignin from 415 to 1,150 Da, however the polymerization catalyzed by laccase was not accomplished by the effective lignin polymerization followed by an efficient separation.

Similar content being viewed by others

References

CONAB (National Supply Company): The sugarcane introduction in Brazil will reach a new record. http://www.conab.gov.br (2011). Accessed 12 Sept 2012

Goldstein, I.S.: Organic Chemicals from Biomass. CRC Press, Boca Raton (1981)

Mussato, S.I., Fernandes, M., Milagres, A.M.F., Roberto, I.C.: Effect of hemicellulose and lignin on enzymatic hydrolysis of cellulose from brewer‘s spent grain. Enzyme Microb. Technol. 34, 124–129 (2008)

Cherubini, F., Strømman, A.H.: Chemicals from lignocellulosic biomass: opportunities, perspectives, and potential of biorefinery systems. Biofuel Bioprod Bioref. 5, 548–561 (2011). doi:10.1002/bbb.297

Canilha, L., Santos, V.T.O., Rocha, G.J.M., Silva, J.B.A., Giulietti, M., Silva, S.S., et al.: A study on the pretreatment of a sugarcane bagasse sample with dilute sulfuric acid. J. Ind. Microbiol. Biotechnol. 38, 1467–1475 (2011)

Paturau, J.M.: By-products of the Cane Sugar Industry, 3rd edn. Elsevier, Amsterdam (1989)

Sanchez, O.J., Cardona, C.A.: Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour. Technol. 99(13), 5270–5295 (2008)

Pietrobon, V.C.: Hidrólise do bagaço de cana-de-açúcar pré-tratado com ácido e álcali utilizando enzimas microbianas comerciais. Universidade de São Paulo, Master Dissertation, Piracicaba (2008)

Rocha, G.J.M.: Polimerização enzimática de lignina solúvel contida em um efluente proveniente da deslignificação alcalina de bagaço de cana. Universidade de São Paulo, Master Dissertation, São Paulo (1995)

Belgacem, N.M., Blayo, A., Gandini, A.: Organosolv lignin a filler in inks, varnishes and paints. Ind Crop Prod. 18, 145–153 (2004)

Stewart, D.: Lignin as a base material for materials applications: chemistry, application and economics. Ind Crop Prod. 27, 202–207 (2008)

The International Lignin Institute: About Lignin. http://www.ili-lignin.com/aboutlignin.php (2009). Accessed 06 July 2012

Northey, R.A.: Low cost uses of lignin in materials and chemicals from biomass. Am. Chem. Soc. Symp. 476, 146–175 (1968)

Monteil-Rivera, F., Phuong, M., Ye, M., Halasz, A., Hawari, J.: Isolation and characterization of herbaceous lignins for applications in biomaterials. Ind Crop Prod. 41, 356–364 (2012)

Schuchardt, U., Rodrigues, J.A.R., Cotrim, A.R., Costa, J.L.M.: Liquefaction of hydrolytic eucalyptus lignin with formate in water, using batch and continuous- flow reactors. Bioresour. Technol. 44, 123–129 (1993)

Vassão, D.G., Davin, L.B., Lewis, N.G.: Metabolic Engineering of Plant Allyl/Propenyl Phenol and Lignin Pathways: Future Potential for Biofuels/Bioenergy, Polymer Intermediates and Specialty Chemicals?. Elsevier Publishers, Oxford, UK (2007)

Mattinen, M.L., Suortti, T., Gosselink, R., Argyropoulos, D.S., Evtuguin, D., Suurnakki, A., et al.: Lignin polymerization by laccase. Bioresour. 3(2), 549–565 (2008)

Boerjan, W., Ralph, J., Baucher, M.: Lignin biosynthesis. Annu. Rev. Plant Biol. 54, 519–546 (2003)

Weng, J.K., Chapple, C.: The origin and evolution of lignin biosynthesis. New Phytol. 187, 273–285 (2010)

Greppin, H., Penel, C., Gaspart, T.: Molecular and Physical Aspects of Plant Peroxidise, vol. 440. University of Geneva, Geneva (1986)

Wagner, M., Niceli, A.J.: Treatment of a foul condensate from kraft pulping with horseradish peroxidase and hydrogen peroxide. Water. Res. 35(2), 485–495 (2001)

Azevedo, A.M., Martins, V.C., Prazeres, D.M., Vojinović, V., Cabral, J.M., Fonseca, L.P.: Horseradish peroxidase: a valuable tool in biotechnology. Biotechnol. Ann Rev. 9, 199–247 (2003)

Bania, I., Mahanta, R.: Evaluation of peroxidases from various plant sources. Int. J. Sci. Res. Public. 2(5), 1–4 (2012)

Higuchi, T.: Ito: further studies on phenol oxidase related to the lignin biosynthesis. J. Biochem. 45, 575–579 (1958)

Guerra, A., Ferraz, A., Cotrim, A.R., Silva, F.T.: Polymerization of lignin fragments contained in a model effluent by polyphenol oxidases and horseradish peroxidase/hydrogen peroxide system. Enzyme. Microb. Technol. 26(5–6), 315–323 (2000)

Forss, K., Jokinen, K., Savolainen, M., Williansan, H.: Utilization of Enzymes for Effluent Treatment in the Pulp and Paper Industry, vol. 10. Paperi ja Puu, Helsinki (1989)

Xu, F., Shin, W., Brown, S., Wahleithner, J.A., Sundaram, U.M., Solomon, E.I.: A study of a series of recombinant fungal laccases and bilirubin oxidase that exhibit significant differences in redox potential, substrate specificity, and stability. Biochim. Biophys. Acta 1292, 303–311 (1996)

Madhavi, V., Lele, S.S.: Laccasse: properties and applications. Bioresour. 4(4), 1694–1717 (2009)

Roy-Arcand, L., Archibald, F.S.: Direct dechlorination of chlorophenolic compounds by laccases from Trametes (Coriolus) versicolor. Enzyme Microb. Technol. 13, 194–203 (1991)

Bohlin, C., Lundquist, K., Jönsson, L.J.: Oxidation of the erythro and threo forms of the phenolic lignin model compound 1-(4-hydroxy-3-methoxyphenyl)-2-(2-methoxyphenoxy)-1,3-propanediol by laccases and model oxidants. Bioorg. Chem. 37(5), 143–148 (2009)

A. Kunamneni, A. Ballesteros, F.J. Plou, M. Alcalde, Fungal laccase: a versatile enzyme for biotechnological applications. Commun. Curr. Res. Educ. Topic. Trends. Appl. Microbiol. A. Méndez-Vilas (Ed.). 233–245 (2007)

Archibald, F.S., Bourbonnais, R., Jurasek, L., Paice, M.G., Reid, I.D.: Kraft pulp bleaching and delignification by Trametes versicolor. J. Biotechnol. 53, 215–336 (1997)

Davis, S., Burns, R.G.: Decolorization of phenolic effluents by soluble and immobilized phenol oxidases. Appl. Microbiol. Biotechnol. 32, 721–724 (1978)

Silva, F.T.: Obtenção de insumos químicos a partir do aproveitamento integral do bagaço de cana. Unicamp/Instituto de Química, Tese de Doutorado, Campinas (1995)

G.J.M. Rocha, F.T. Silva, U. Schuchardt, Improvement of a rapid UV spectrophotometric method for determination of lignin in alkaline solutions. In: Brazilian Symposium on the chemistry of lignin and other wood components, 3, Belo horizonte, 08–10. Programme and Abstracts, Belo Horizonte, p 73 (1993)

Szkarz, G.D., Antibus, R.K., Sinsabaugh, R.L., Linkins, A.: Purification of phenol oxidases and peroxidases by wood rotting fungi Mycologie. New York 81(2), 234–240 (1989)

C. Barnett, K. Loferski, C. Wartman, (eds.) Experimental procedures routinely, applied in the wood chemistry laboratory. Department of Forest Products Madison, USA (1982)

Lenz, B.L.: Application of nuclear magnetic resonance spectroscopy to characterization of lignin. Tappi J. 51, 511–519 (1968)

Chen, C.L., Robert, D.: Characterization of lignin by 1H and 13C NMR spectroscopy. Methods Enzyme. 161, 137–175 (1988)

Livernoche, D., et al.: Removal of color from kraft mill wastewaters with cultures of white-rot fungi and with immobilized mycelium of Coriolus versicolor. Biotechnol. Bioeng. 25, 2055–2065 (1983)

Moore, K.L., Moronne, M.M., Mehlhorn, R.: Electron spin resonance of peroxidase activity and kinetics. Arch. Biochem. Biophys. 299, 47–56 (1992)

Goldshimidt, O.: Ultraviolet spectra. In: Sarkanen, K.V., Ludwid, L.H. (eds.) Lignin- Occurrence Formation Structure and Reaction, pp. 241–266. Wiley Interscience, New York (1977)

Fernandez, N., Morck, R., Johnsrud, S.C., Kringstad, K.P.: Carbon-13 NMR study on lignin from bagasse. Holzforschung 44, 35–38 (1990)

Faix, O.: Classification of lignins from different botanical origins by FI–IR spectroscopy. Holzforschung 45, 21–27 (1991)

Atsushi, K., Azuma, J., Koshijima, T.: Lignin- carbohydrate complexes and phenolic acids in bagasse. Holzforshung 38, 141–149 (1984)

Chen, C.L., Robert, D.: Characterization of lignin by 1H and 13C NMR spectroscopy. In: Wood, W.A., Fellog, S. (eds.) Methods in Enzymology 161B. Academic, Orlando (1988)

Ralph, J., Landucci, L.L.: NMR of lignins. In: Heitner, C., Dimmel, D.R. (eds.) Lignins, pp. 137–234. Marcel Dekker, New York (2010)

C.H. Ludwig, Magnetic resonance spectra. In: K.V. Sarkanen, L.H. Ludwid (eds.) Lignin-occurrence formation structure and reaction, New York; Wiley Interscience. p 299–344 (1977)

N. Fernandez, L. Suty, Studies in sugar cane bagasse lignin. In: The Ekman Days. Int. Symp. Wood. Pulp. Chem. 5, 52–60 (1981)

Acknowledgments

The authors gratefully acknowledge the support given by Universidade de São Paulo- Escola de Engenharia de Lorena- EEL-USP.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rocha, G.J.M., Nascimento, V.M. & da Silva, V.F.N. Enzymatic Bioremediation of Effluent from Sugarcane Bagasse Soda Delignification Process. Waste Biomass Valor 5, 919–929 (2014). https://doi.org/10.1007/s12649-014-9316-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-014-9316-5