Abstract

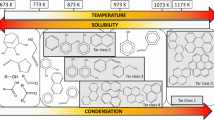

Gasification technology is an attractive alternative for the thermal treatment of solid wastes, producing a high energy value hydrogen rich syngas. The presence of tar in the produced gas diminishes its quality and potential use in further processes; for this reason the reduction of tar in waste gasification is a major challenge. In this work the pyrolysis/gasification of refuse derived fuel (RDF) from municipal solid wastes, was investigated using a two-stage reaction system with Ni/SiO2 catalysts prepared by a sol–gel method varying the citric acid concentration (CA). The fresh and reacted catalysts were characterised for surface area and pore size distribution, temperature programmed oxidation, and high resolution scanning electron microscopy. The effect of the nickel to citric acid ratio (Ni:CA) was evaluated in terms of the characteristics and performance of the Ni/SiO2 catalysts. The results showed that the prepared Ni/SiO2 catalysts exhibited a relatively high surface area and an increase in pore size distribution as the Ni:CA ratio was increased. The efficiency of the prepared catalysts on tar reduction and hydrogen production was examined during the pyrolysis/gasification of RDF; the results were compared with a blank experiment using a bed of sand. The tar fraction was quantified using gas chromatography/mass spectrometry. A low tar concentration of ~0.2 mgtar/gRDF was attained using the catalysts with Ni:CA ratios of 1:1 and 1:3; additionally a high hydrogen concentration (58 vol%), and low CH4 (2.2 vol%) and C2–C4 concentrations (0.8 vol%), were attained using the catalyst with a Ni:CA ratio of 1:3. A higher tar concentration of ~1.7 mgtar/gRDF was attained using the bed of sand, while the hydrogen production was remarkably decreased. The major tar compounds identified in the tar samples using the Ni/SiO2 catalysts were phenol, cresols, naphthalene, fluorene, and phenanthrene.

Similar content being viewed by others

References

Choudhary, T.V., Choudhary, V.R.: Energy-efficient syngas production through, catalytic oxy-methane reforming reactions. Angew. Chem. Int. Edit. 47(10), 1828–1847 (2008). doi:10.1002/anie.200701237

Edwards, P.P., Kuznetsov, V.L., David, W.I.F.: Hydrogen energy. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 365(1853), 1043–1056 (2007). doi:10.1098/rsta.2006.1965

Dalai, A.K., Batta, N., Eswaramoorthi, I., Schoenau, G.J.: Gasification of refuse derived fuel in a fixed bed reactor for syngas production. Waste Manage. 29(1), 252–258 (2009). doi:10.1016/j.wasman.2008.02.009

Belgiorno, V., De Feo, G., Della Rocca, C., Napoli, R.M.A.: Energy from gasification of solid wastes. Waste Manage. 23(1), 1–15 (2003). doi:10.1016/s0956-053x(02)00149-6

Li, J.F., Liao, S.Y., Dan, W.Y., Jia, K.L., Zhou, X.R.: Experimental study on catalytic steam gasification of municipal solid waste for bioenergy production in a combined fixed bed reactor. Biomass Bioenergy 46, 174–180 (2012)

Devi, L., Ptasinski, K.J., Janssen, F.J.J.G.: A review of the primary measures for tar elimination in biomass gasification processes. Biomass Bioenergy 24(2), 125–140 (2003). doi:10.1016/s0961-9534(02)00102-2

Neeft, J.P.A., Knoef, H.A.M., Onaji, P., Nederland, S.E.C., Group, B.B.T.: Behaviour of tar in biomass gasification systems: tar related problems and their solutions. Novem (1999)

Abu El-Rub, Z., Bramer, E.A., Brem, G.: Review of catalysts for Tar elimination in biomass gasification processes. Ind. Eng. Chem. Res. 43(22), 6911–6919 (2004)

Caballero, M.A., Corella, J., Aznar, M.P., Gil, J.: Biomass gasification with air in fluidized bed. Hot gas cleanup with selected commercial and full-size nickel-based catalysts. Ind. Eng. Chem. Res. 39(5), 1143–1154 (2000)

Miccio, F., Moersch, O., Spliethoff, H., Hein, K.R.G.: Generation and conversion of carbonaceous fine particles during bubbling fluidised bed gasification of a biomass fuel. Fuel 78(12), 1473–1481 (1999)

Li, C., Suzuki, K.: Tar property, analysis, reforming mechanism and model for biomass gasification—an overview. Renew. Sustain. Energy Rev. 13(3), 594–604 (2009). doi:10.1016/j.rser.2008.01.009

Simell, P., Ståhlberg, P., Kurkela, E., Albrecht, J., Deutsch, S., Sjöström, K.: Provisional protocol for the sampling and analysis of tar and particulates in the gas from large-scale biomass gasifiers. Version 1998. Biomass Bioenergy 18(1), 19–38 (2000). doi:10.1016/s0961-9534(99)00064-1

Neeft, J.P.A., Knoef, H.A.M., Zielke, U., Sjostrom, K., Hasler, P., Simell, P.A.: Guideline for sampling and analysis of tar and particles in biomass producer gases. In: Tar Protocol. ECN ERK-CT1999-2002, Pette, Nederland (1999)

DD CEN/TS 15439 Biomass Gasification—Tar And Particles In Product Gases—Sampling And Analysis. In: CEN Technical Specification, (2006)

Adegoroye, A., Paterson, N., Li, X., Morgan, T., Herod, A.A., Dugwell, D.R., Kandiyoti, R.: The characterisation of tars produced during the gasification of sewage sludge in a spouted bed reactor. Fuel 83(14–15), 1949–1960 (2004). doi:10.1016/j.fuel.2004.04.006

Andersson, K., Levin, J.-O., Nilsson, C.-A.: Sampling and analysis of particulate and gaseous polycyclic aromatic hydrocarbons from coal tar sources in the working environment. Chemosphere 12(2), 197–207 (1983). doi:10.1016/0045-6535(83)90162-5

Baumhakl, C., Karellas, S.: Tar analysis from biomass gasification by means of online fluorescence spectroscopy. Opt. Lasers Eng. 49(7), 885–891 (2011). doi:10.1016/j.optlaseng.2011.02.015

Li, J., Yan, R., Xiao, B., Liang, D.T., Du, L.: Development of Nano-NiO/Al2O3 catalyst to be used for tar removal in biomass gasification. Environ. Sci. Technol. 42(16), 6224–6229 (2008). doi:10.1021/es800138r

Sutton, D., Kelleher, B., Ross, J.R.H.: Review of literature on catalysts for biomass gasification. Fuel Process. Technol. 73(3), 155–173 (2001). doi:10.1016/s0378-3820(01)00208-9

Bangala, D.N., Abatzoglou, N., Martin, J.-P., Chornet, E.: Catalytic gas conditioning: application to biomass and waste gasification. Ind. Eng. Chem. Res. 36(10), 4184–4192 (1997). doi:10.1021/ie960785a

Wu, C.F., Williams, P.T.: A novel Nano-Ni/SiO(2) catalyst for hydrogen production from steam reforming of ethanol. Environ. Sci. Technol. 44(15), 5993–5998 (2010). doi:10.1021/Es100912w

Blanco, P.H., Wu, C., Onwudili, J.A., Williams, P.T.: Characterization of tar from the pyrolysis/gasification of refuse derived fuel: influence of process parameters and catalysis. Energy Fuels 26(4), 2107–2115 (2012). doi:10.1021/ef300031j

Park, H.J., Park, S.H., Sohn, J.M., Park, J., Jeon, J.-K., Kim, S.-S., Park, Y.-K.: Steam reforming of biomass gasification tar using benzene as a model compound over various Ni supported metal oxide catalysts. Bioresour. Technol. 101(1, Supplement), S101–S103 (2010). doi:10.1016/j.biortech.2009.03.036

Taylor, A.D., DiLeo, G.J., Sun, K.: Hydrogen production and performance of nickel based catalysts synthesized using supercritical fluids for the gasification of biomass. Appl. Catal. B 93(1–2), 126–133 (2009). doi:10.1016/j.apcatb.2009.09.021

Sutton, D., Kelleher, B., Doyle, A., Ross, J.R.H.: Investigation of nickel supported catalysts for the upgrading of brown peat derived gasification products. Bioresour. Technol. 80(2), 111–116 (2001)

Li, J., Liu, J., Liao, S., Zhou, X., Yan, R.: Syn-gas production from catalytic steam gasification of municipal solid wastes in a combined fixed bed reactor. In: International Conference on Intelligent System Design and Engineering Application 2010, pp. 530–534.

Kim, P., Kim, Y., Kim, H., Song, I.K., Yi, J.: Synthesis and characterization of mesoporous alumina with nickel incorporated for use in the partial oxidation of methane into synthesis gas. Appl. Catal. A 272(1–2), 157–166 (2004). doi:10.1016/j.apcata.2004.05.055

Goncalves, G., Lenzi, M.K., Santos, O.A.A., Jorge, L.M.M.: Preparation and characterization of nickel based catalysts on silica, alumina and titania obtained by sol-gel method. J. Non-Cryst. Solids 352, 3697–3704 (2006)

Wu, C., Williams, P.T.: Hydrogen production from steam reforming of ethanol with nano-Ni/SiO2 catalysts prepared at different Ni to citric acid ratios using a sol–gel method. Appl. Catal. B 102(1–2), 251–259 (2011). doi:10.1016/j.apcatb.2010.12.005

Tomiyama, S., Takahashi, R., Sato, S., Sodesawa, T., Yoshida, S.: Preparation of Ni/SiO2 catalyst with high thermal stability for CO2-reforming of CH4. Appl. Catal. A 241(1–2), 349–361 (2003). doi:10.1016/s0926-860x(02)00493-3

Takahashi, R., Sato, S., Sodesawa, T., Kawakita, M., Ogura, K.: High surface-area silica with controlled pore size prepared from nanocomposite of silica and citric acid. J. Phys. Chem. B 104(51), 12184–12191 (2000). doi:10.1021/Jp002662g

Takahashi, R., Sato, S., Sodesawa, T., Suzuki, M., Ichikuni, N.: Ni/SiO2 prepared by sol-gel process using citric acid. Microporous Mesoporous Mater. 66(2–3), 197–208 (2003). doi:10.1016/j.miromeso.2003.09.007

Buah, W.K., Cunliffe, A.M., Williams, P.T.: Characterization of products from the pyrolysis of municipal solid waste. Process Saf. Environ. Prot. 85(5), 450–457 (2007). doi:10.1205/psep07024

Sing, K.S.W., Everett, D.H., Haul, R.A.W., Moscou, L., Pierotti, R.A., Rouquerol, J., Siemieniewska, T.: Reporting physisorption data for gas solid systems with special reference to the determination of surface-area and porosity (recommendations 1984). Pure Appl. Chem. 57(4), 603–619 (1985)

Rouquerol, F., Rouquerol, J., Sing, K.S.W.: Adsorption by powders and porous solids. Academic Press, London (1999)

Kim, J.-W., Mun, T.-Y., Kim, J.-O., Kim, J.-S.: Air gasification of mixed plastic wastes using a two-stage gasifier for the production of producer gas with low tar and a high caloric value. Fuel 90(6), 2266–2272 (2011). doi:10.1016/j.fuel.2011.02.021

Pinto, F., André, R.N., Franco, C., Lopes, H., Gulyurtlu, I., Cabrita, I.: Co-gasification of coal and wastes in a pilot-scale installation 1: effect of catalysts in syngas treatment to achieve tar abatement. Fuel 88(12), 2392–2402 (2009). doi:10.1016/j.fuel.2008.12.012

Blanco, P.H., Wu, C., Onwudili, J.A., Williams, P.T.: Characterization and evaluation of Ni/SiO2 catalysts for hydrogen production and tar reduction from catalytic steam pyrolysis-reforming of refuse derived fuel. Appl. Catal. B Environ. 134–135, 238–250 (2013). doi:10.1016/j.apcatb.2013.01.016

Han, J., Kim, H.: The reduction and control technology of tar during biomass gasification/pyrolysis: an overview. Renew. Sustain. Energy Rev. 12(2), 397–416 (2008). doi:10.1016/j.rser.2006.07.015

Wolfesberger-Schwabl, U., Aigner, I., Hofbaur, H.: Mechanism of tar generation during fluidized bed gasification and low temperature pyrolysis. Ind. Eng. Chem. Res. 51, 13001–13007 (2012). doi:10.1021/ie300827d

Hernandez, J.J., Ballesteros, R., Aranda, G.: Characterisation of tars from biomass gasification: effect of the operating conditions. Energy 50, 333–342 (2013). doi:10.1016/j.energy.2012.12.005

Abu El-Rub, Z., Bramer, E.A., Brem, G.: Experimental comparison of biomass chars with other catalysts for tar reduction. Fuel 87(10–11), 2243–2252 (2008). doi:10.1016/j.fuel.2008.01.004

Matas Güell, B., Babich, I.V., Lefferts, L., Seshan, K.: Steam reforming of phenol over Ni-based catalysts—a comparative study. Appl. Catal. B Environ. 106(3–4), 280–286 (2011). doi:10.1016/j.apcatb.2011.05.012

Larsen, E., Egsgaard, H., Pedersen, K., Zielke, U., Brandt, P.: Tar compounds in condensates from different types of gasifiers. In: Kyritsis, S. (ed.) 1st World Conference on Biomass for Energy and Industry, Sevilla, Spain, 5–9 June 2000, p. 2137. James & James (Science Publishers) Ltd

Wu, C., Williams, P.T.: Hydrogen production by steam gasification of polypropylene with various nickel catalysts. Appl. Catal. B 87(3–4), 152–161 (2009). doi:10.1016/j.apcatb.2008.09.003

Wu, C., Williams, P.T.: Investigation of coke formation on Ni–Mg–Al catalyst for hydrogen production from the catalytic steam pyrolysis-gasification of polypropylene. Appl. Catal. B 96(1–2), 198–207 (2010). doi:10.1016/j.apcatb.2010.02.022

Devi, L., Ptasinski, K.J., Janssen, F.J.J.G.: Pretreated olivine as tar removal catalyst for biomass gasifiers: investigation using naphthalene as model biomass tar. Fuel Process. Technol. 86(6), 707–730 (2005). doi:10.1016/j.fuproc.2004.07.001

Wang, C., Dou, B., Chen, H., Song, Y., Xu, Y., Du, X., Zhang, L., Luo, T., Tan, C.: Renewable hydrogen production from steam reforming of glycerol by Ni–Cu–Al, Ni–Cu–Mg, Ni–Mg catalysts. Int. J. Hydrogen Energy 38(9), 3562–3571 (2013). doi:10.1016/j.ijhydene.2013.01.042

Acknowledgments

The authors would like to thank the National Council of Science and Technology of Mexico (Conacyt) for a scholarship of one of us: PHB. Funding from the UK Science & Engineering Research Council (Grant EP/G036608/1) is also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Blanco, P.H., Wu, C., Onwudili, J.A. et al. Catalytic Pyrolysis/Gasification of Refuse Derived Fuel for Hydrogen Production and Tar Reduction: Influence of Nickel to Citric Acid Ratio Using Ni/SiO2 Catalysts. Waste Biomass Valor 5, 625–636 (2014). https://doi.org/10.1007/s12649-013-9254-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-013-9254-7