Abstract

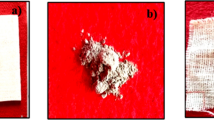

This investigation focused to make use of pineapple fabric and peanut husk ash (PHA) biosilica particles to develop lightweight polyester bio-composites for automobile and inexpensive technological applications. In order to create biosilica particles from peanut husk, a thermo-mechanical procedure and an aqueous solution method are used and silane-surface treatment is performed on it. The uniqueness of the current work lies in the evaluation of the effects of PHA biosilica particulates added at various volume percentages on the mechanical (tensile, flexural, impact, hardness, ILSS and wear characteristics), fatigue, and ballistic characteristics of polyester composites reinforced with 45 vol. % pineapple fabric. The pineapple fabric and PHA biosilica particles treated with 3 vol. % silane exhibit the highest tensile, flexural, impact, and interlaminar shear strengths (128 MPa, 184 MPa, 5.68 J, and 27 MPa, respectively). While composites constructed with 5 vol.% PHA biosilica particles have a maximum hardness of 81 Shore-D, a minimum specific wear rate of 0.005 mm3/Nm, and a coefficient of friction (COF) of 0.48, respectively. Additionally, these composites exhibit good ballistic properties with the least penetration impact, and their maximum life counts of 38,830, 29,624, and 21,042 are obtained at UTS stress levels of 25%, 50%, and 75%. These polyester composites, which combine pineapple fabric with silane-treated PHA biosilica particles, should work well in a range of technical applications, including automotive parts like door and window frames, sporting goods, and domestic appliances.

Similar content being viewed by others

Data Availability

All Data available in manuscript itself.

References

Saha et al (2022) Polym Adv Technol 33(10):3201–3215. https://doi.org/10.1002/pat.5772

Alshahrani H, Prakash VA (2022) Int J Biol Macromol

Alshahrani H, Prakash VA (2022) Prog Org Coat 172:107080

Chaudhary V, Ahmad F (2020) Ploym Test 1862(2):106792

ArunPrakash VR, Viswanathan R (2019) Int J Plast Technol 23(2):207–217

Jawaid M et al (2017) Lignocellulosic fibre and biomass-based composite materials

Aggarwal M, Chatterjee A (2022) Indian J Fibre Text Res 47:309–317

Singh H, Chatterjee A (2020) Cellulose 27(5):2555–2567

Buitrago B et al (2015) J Nat Fibers 12(4):357–367

Motaleb KZMA (2018) Int J Compos Mater 8(2):32–37

Zeleke Y et al (2022) Int J Sustain Eng 15(1):146–154

Abir et al (2021) J Mater: Des Appl. https://doi.org/10.1177/1464420721990851

Abiret al (2021) J Polym Res. https://doi.org/10.1007/s10965-021-02435-y

Poomathi S et al (2022) Biomass Convers Bioref 1:1–9

Kumar et al (2022) Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-03293-4

VR AP et al (2020) Silicon 12(11):2533–2544

Kumar et al (2022) J Mater Cycles Waste Manag 24:2527–2544. https://doi.org/10.1007/s10163-022-01499-2

Alshahrani H, VR AP (2022) Biomass Convers Bioref 1:1–12

Jayabalakrishnan D et al (2022) Polym Compos 43(1):493–502

Rajadurai A (2016) Appl Surf Sci 384:99–106

Prakash VA, Viswanthan R (2019) Compos A Appl Sci Manuf 118:317–326

Manikandan G et al (2021) Polym Compos 42(1):181–190

Saha et al (2021) Polym Compos 42(9):4497. https://doi.org/10.1002/pc.26164

Alshahrani H, Prakash VA (2023) Ind Crops Prod 191:115967

Murugan MA et al (2020) Silicon 12(8):1847–1856

Alshahrani H, Prakash VA (2022) J Clean Prod 374:133931

Arun Prakash VR et al (2020) Biomass Convers Bioref

Author information

Authors and Affiliations

Contributions

A.Sivakumar: Research, Drafting and proofing.

K S KarthiVinith, P.Sathiamurthi: Conceptualization.

L. Savadamuthu: testing support.

Corresponding author

Ethics declarations

Ethical Approval

NA.

Consent to Participate

Yes.

Consent for Publication

Yes.

Competing Interests

There is no competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sivakumar, A., Vinith, K.S.K., Savadamuthu, L. et al. Development of Pineapple Fibre and Biosilica Toughened Polyester Sustainable Biocomposite of Few Mechanical Properties for Automobile Application. Silicon 15, 3507–3514 (2023). https://doi.org/10.1007/s12633-022-02284-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02284-4