Abstract

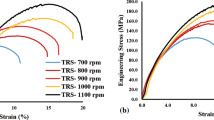

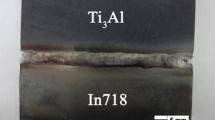

The welding process is used to join similar or dissimilar alloys, resulting in severe joint softening, uneven grain structure, and inevitable deficiencies. The friction stir process (FSP) can reduce the grain size and enhance the tensile properties. In this work, the FSP was applied to Si-rich TIG welded joints to enhance the tensile properties and microstructure of the TIG-welded joints by variation of rotational tool speed (TRS), and it was observed that the TIG welding defects (solidification defects, micro-voids, porosity, coarse grain structure) were removed, and the grain size of the TIG weldment was decreased. The coarse eutectic Al13Fe4 and Mg2Si phases were transformed into very small phases in the TIG + FSPed joints. The homogenization of the primary α-Al exists in the TIG welded joints was continuously enhanced as the TRS increased. The processed zone with high TRS (1100 rpm) demonstrated higher tensile strength (102.76 MPa), whereas the TIG weldment using filler ER4043 was employed to have an average tensile strength of 72.14 MPa. The ultrafine grain structure of 5.14 μm was found in the TIG + FSPed weldment with a TRS of 1100 rpm, while the coarse grain size of 20.85 μm was found in the TIG weldment.

Similar content being viewed by others

Data Availability

Data and materials will be available upon request.

Code Availability

Not applicable.

References

Mishra RS, Ma ZY, Charit I (2003) Friction stir processing: a novel technique for fabrication of surface composite. Mater Sci Eng A 341(1–2):307–310

Mehdi H, Mishra RS (2021) Effect of multi-pass friction stir processing and SiCnanoparticles on microstructure and mechanical properties of AA6082-T6. Adv Ind Manuf Eng 3

Husain Mehdi RS, Mishra (2019) Study of the influence of friction stir processing on tungsten inert gas welding of different aluminum alloy. SN Appl Sci 1:712. https://doi.org/10.1007/s42452-019-0712-00

Fayomi J, Popoola API, Popoola OM, Oladijo OP, Fayomi OSI (2019) Tribological and microstructural investigation of hybrid AA8011/ZrB2-Si3N4 nanomaterials for service life improvement. Results Phys 14:102469

Li Quan WU, Ai-ping ZHAO, Yue WANG, Guo-qing YAN, Dong-yang (2015) WU Hui-qiang. Fracture behavior of double-pass TIG welded 2219-T8 aluminum alloy joints under transverse tensile test [J]. Trans Nonferrous Met Soc China 25(6):1794–1803

Saeidi M, Barmouz M, Givi MKB (2015) Investigation on AA5083/AA7075 + Al2O3 joint fabricated by friction stir welding: characterizing microstructure, corrosion and toughness behavior. Mater Res (6):1156–1162

Mehdi H, Mishra RS (2021) Microstructure and mechanical characterization of TIG-welded joint of AA6061 and AA7075 by friction stir processing. ProcInstMechEngLJ Mater Des Appl 235(11):2531–2546

Husain Mehdi RS, Mishra (2020) Influence of friction stir processing on weld temperature distribution and mechanical properties of TIG welded joint of AA6061 and AA7075. Trans Indian Inst Met 73:1773–1788

Mehdi H, Mishra RS (2020) Effect of friction stir processing on microstructure and mechanical properties of TIG welded joint of AA6061 and AA7075. Metallogr Microstruct Anal 9:403–418

Mehdi H, RS, Mishra (2020) Investigation of mechanical properties and heat transfer of welded joint of AA6061 and AA7075 using TIG + FSP welding approach. J Adv Joining Process 1:100003

Elanchezhian C, Vijaya Ramnath B, Venkatesan P, Sathish S, Vignesh T, Siddharth RV, Vinay B, Gopinath K (2014) Parameter optimization of friction stir welding of AA8011-6062. Procedia Eng 97:775–782

Verma RP, Pandey KN, Sharma Y (2015) Effect of ER4043 and ER5356 filler wire on mechanical properties and microstructure of dissimilar aluminium alloys, 5083-O and 6061–T6 joint, welded by the metal inert gas welding. Proc Inst Mech Eng B J Eng Manuf 229(6):1021–1028

El-Batahgy A, Kutsuna M (2009) Laser beam welding of AA5052, AA5083, and AA6061 aluminum alloys. Adv Mater Sci Eng 1–9. https://doi.org/10.1155/2009/974182

Chen YB, Lei ZL, Li LQ, Wu L (2006) Experimental study on welding characteristics of CO2 laser TIG hybrid welding process. Sci Technol Weld Joining 11(4):403–411

Song G, Luo Z (2011) The influence of laser pulse waveform on laser–TIG hybrid welding of AZ31B magnesium alloy. Opt Lasers Eng 49(1):82–88

Takhti S, Reihanian M, Ashrafi A (2015) Microstructure characterization and mechanical properties of gas tungsten arc welded cast A356 alloy. Trans Nonferrous Met Soc China 25:2137–2146

Chen Y-B, Miao Y-G, Li L-Q, Wu L (2009) Joint performance of laser-TIG double-side welded 5A06 aluminum alloy. Trans Nonferrous Met Soc China 19(1):26–31

Chen Y-B, Miao Y-G, Li L-Q, Wu L (2008) Arc characteristics of laser-TIG double-side welding. Sci Technol Weld Joining 13(5):438–444

Shen J, Xu N (2012) Effect of preheat on TIG welding of AZ61 magnesium alloy. Int J Minerals Metall Mater 19:360–363

Ramana V, Yelamasetti B, Vardhan V (2021) Study on weldability and effect of post heat treatment on mechanical and metallurgical properties of dissimilar AA 2025, AA 5083 and AA7075 GTAW weld joints. Mater Today Proc 46(1):878–882

Aliakbari S, Ketabchi M, Mirsalehi SE (2019) Effect of through-thickness friction stir processing parameters on weld repair and modification of fusion-welded AA6061 aluminum alloy. J of Mater Eng Perform 28:2688–2696

Hassani B, Karimzadeh F, Enayati MH et al (2016) Effect of friction stir processing on microstructure and mechanical properties of AZ91C magnesium cast alloy weld zone. J of Mater Eng Perform 25:2776–2785

Roeen GA, Yousefi SG, Emadi R, Shooshtari M, Lotfian S (2021) Remanufacturing the AA5052 GTAW welds using friction stir processing. Metals 11(5):749

Silva J, Costa JM, Loureiro A, Ferreira JM (2013) Fatigue behaviour of AA6082-T6 MIG welded butt joints improved by friction stir processing. Mater Des 51:315–322

Rhodes CG, Mahoney MW, Bingel WH (1997) Effects of friction stir welding on microstructure of 7075 aluminium. Scripta Mater 36:69–75

Su JQ, Nelson TW, Mishra R, Mahoney M (2003) Microstructural investigation of friction stir welded 7050-T651 aluminium. Acta Mater 51:713–729

Thomas WM et al (1991) International Patent Application, PCT/GB92/02203 and GB Patent Application No 9125978.8

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R Rep 50:1–78

Lombard H, Hattingh DG, Steuwer A, James MN (2008) Optimising FSW process parameters to minimise defects and maximise fatigue life in 5083-H321 aluminium alloy. Eng Fract Mech 75(3–4):341–354

Sadoun AM, Wagih A, Fathy A, Essa ARS (2019) Effect of tool pin side area ratio on temperature distribution in friction stir welding. Results in Physics 15:102814

Mastanaiah P, Abhay Sharma G, Madhusudhan Reddy (2016) Dissimilar friction stir welds in AA2219-AA5083 aluminium alloys: Effect of process parameters on material inter-mixing, defect formation, and mechanical properties. Trans Indian Inst Met 69(7):1397–1415

Taban E, Kaluc E (2006) Microstructural and mechanical properties of double-sided MIG, TIG and friction stir welded 5083-H321 aluminium alloy. Kovove Mater 44:25–33

Mabuwa S, Msomi V (2020) The impact of submerged friction stir processing on the friction stir welded dissimilar joints. Mater Res Express 7:096513

Singh D, Rao PN, Jayaganthan R (2013) Effect of deformation temperature on mechanical properties of ultrafine grained Al – Mg alloys processed by rolling. Mater Des 50:646–655

Lee YB, Shin DH, Park KT, Nam WJ (2004) Effect of annealing temperature on microstructures and mechanical properties of a 5083 Al alloy deformed at cryogenic temperature. Scr Mater 51(4):355–359

Ma ZY (2008) Friction stir processing technology: a review. Metall Mater Trans A Phys Metall Mater Sci 39 A(3):642–658

Su JQ, Nelson TW, Sterling CJ (2006) Grain refinement of aluminum alloys by friction stir processing. Philos Mag 86(1):1–24

Byeli AV, Minevich AA, Stepanenko AV, Gick LG, Kholodilov OV (1992) Wear resistance and structure of (Ti, Al)N coatings. J Phys D Appl Phys 25(1A):A292–A296

Mallesh, Jakanur (2016) Effect of Ti addition on the tribological wear behaviour of hypereutectic Al-Si alloys at elevated temperatures. Int J Eng Sci Res Technol 5(3):187–193

Dubey AM, Kumar A, Yadav AK (2017) Wear behaviour of friction stir weld joint of cast Al (4–10%) Cu alloy welded at different operating parameters. J Mater Process Technol 240:87–97

Ghasemi-kahrizsangi A, Kashani-Bozorg SF, Moshref-Javadi M (2015) Effect of friction stir processing on the tribological performance of Steel/Al2O3 nanocomposites. Surf Coat Technol 276:507–515

Rastkerdar E, Shamanian M, Saatchi A (2013) Taguchi optimization of pulsed currentGTA welding parameters for improved corrosion resistance of 5083 aluminumwelds. J Mater Eng Perform 22(4):1149–1160

Liu Y et al (2012) Microstructure and mechanical properties of aluminum 5083weldments by gas tungsten arc and gas metal arc welding. Mater Sci Eng A:7–13

Guo Y et al (2018) An investigation on plasma-MIG hybrid welding of 5083 aluminum alloy. Int J Adv Manuf Technol 98(5–8):14331440

Ma T, den Ouden G (1999) Softening behavior of Al-Zn- Mg alloys due to welding. Mater Sci Eng A 266(1–2):198

Temmar M, Hadji M, Sahraoui T (2011) Effect of postweld aging treatment on mechanical properties of tungsten inert gas welded low thickness 7075 aluminium alloy joints. Mater Des 32(6):3532

Marlaud T, Deschamps A, Beley F, Lefebvre W, Baroux B (2010) Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al– Zn–Mg–Cu alloy. Acta Mater 58:4814 (No. 14)

Wang J, Zhou D, Xie L, Li X, Lu Y, Bai Z, Zhou J (2021) Effect of multi-pass friction stir processing on microstructures and mechanical behaviors of as-cast 2A14 aluminum alloy. J Mater Eng Perform 30:3033–3043

Chen Y, Ding H, Cai Z, Zhao J, Li J (2016) Effect of initial base metal temper on microstructure and mechanical properties of friction stir processed Al-7B04 alloy Mater. Sci Eng A 650:396–403

Wang J, Yang K, Zhou D, Xie L, Lu Y, Li X (2021) Investigation on the microstructures and mechanical properties of friction stir processed 2A14 aluminum alloy fabricated by different initial precipitation states, The Int. J Adv Manuf Technol 116:3549–3560

Moslem Paidar OO, Ojo HR, Ezatpour A, Heidarzadeh (2019) Influence of multi-pass FSP on the microstructure, mechanical properties and tribological characterization of Al/B4C composite fabricated by accumulative roll bonding (ARB). Surf Coat Technol 361:159–169

Amini C, Hasanifard S, Zehsaz M et al (2021) Friction stir welding of AA2024-T3: development of numerical simulation considering thermal history and heat generation. Int J Adv Manuf Technol 117:2481–2500

Barmouz M, Besharati Givi MK, Seyfi J (2011) On the role of processing parameters in producing Cu/SiC metal matrix composites via friction stir processing: investigating microstructure, microhardness, wear and tensile behavior. Mater Charact 62:108–117

Barmouz M, Besharati MK, Givi (2011) Fabrication of in situ Cu/SiC composites using multi-pass friction stir processing: evaluation of microstructural, porosity, mechanical and electrical behavior. Compos Part A 42(10):1445–1453

Su P, Gerlich A, North TH, Bendzsak GJ (2013) Material flow during friction stir spot welding. Sci Technol Weld Joining 11(1):61–71

Liu LM, Song G, Liang GL, Wang JF (2005) Mater Sci Eng A 390:76–80

Duan S, Matsuda K, Zou Y, Wang T (2019) Influence of two-stage ageing process and Cu additions on conductive Al alloys based on AA 6063. Mater Res Express 6:106509

Sato YS, Kokawa H, ENnomoto M, Jogan S (1999) Microstructural evolution of 6063 Aluminum during friction-stir welding. Metall Mater Trans A 30:2429–2437

Sunde JK, Marioara CD, Helvoort ATJ, Holmestad R (2018) The evolution of precipitate crystal structures in an Al-Mg-Si(-Cu) alloy studied by a combined HAADFSTEM and SPED approach. Mater Charact 142:458–469

Prangnell PB, Heason CP (2005) Grain structure formation during friction stir welding observed by the ‘stop action technique’. Acta Mater 53:3179–3192

Wang J, Yang K, Zhou D et al (2021) Investigation on the microstructures and mechanical properties of friction stir processed 2A14 aluminum alloy fabricated by different initial precipitation states. Int J Adv Manuf Technol 116:3549–3560

Moharami A, Razaghian A, Babaei B, Ojo OO (2020) Role of Mg2Si particles on mechanical, wear, and corrosion behaviors of friction stir welding of AA6061-T6 and Al-Mg2Si composite. J Compos Mater 2020 54(26):4035–4057

Paidar M, Asgari A, Ojo OO (2018) Mechanical properties and wear behavior of AA5182/WC nanocomposite fabricated by friction stir welding at different tool traverse speeds. J Mater Eng Perform 27:1714–1724

Tan YB, Wang XM, Ma M, Zhang JX, Liu WC, Fu RD, Xiang S (2017) A study on microstructure and mechanical properties of AA3003 aluminum alloy joints by underwater friction stir welding. Mater Charact 127:41

Salah AN, Mabuwa S, Mehdi H et al (2022) Effect of multipass FSP on Si-Rich TIG welded joint of dissimilar aluminum alloys AA8011-H14 and AA5083-H321: EBSD and microstructural evolutions. Silicon. https://doi.org/10.1007/s12633-022-01787-4

Patel VV, Badheka Vand Kumar A (2017) Effect of polygonal pin profiles on friction stir processed superplasticity of AA7075 alloy J. Mater Process Technol 240:68–76

Qin H, Zhang H, Wu H (2015) The evolution of precipitation and microstructure in friction stir welded 2195–T8 Al–Li alloy. Mater Sci Eng A 626:322–329

Moslem Paidar D, Bokov S, Mehrez OO, Ojo (2021) Improvement of mechanical and wear behavior by the development of a new tool for the friction stir processing of Mg/B4C composite. Surf Coat Technol 426:127797

Duan S, Wang T, Zou Y (2019) Double-side friction stir welded cast 2297 Al–Cu–Li Alloy at Various Parameters. Trans Indian Inst Met 72:1733–1741

Mahmoud ERI, Takahashi M, Shibayanagi T, Ikeuchi K (2010) Wear characteristics of surface-hybrid-MMCs layer fabricated on aluminum plate by friction stir processing. Wear 268:1111–1121

Zhang YS, Han Z, Wang K, Lu K (2006) Friction and wear behaviors of nanocrystalline surface layer of pure copper. Wear 260:942–948

Eftekharinia H, Amadeh AA, Khodabandeh A et al (2020) Microstructure and wear behavior of AA6061/SiC surface composite fabricated via friction stir processing with different pins and passes. Rare Met 39:429–435

Wan DT, Hu CF, Bao YW, Zhou YC (2007) Effect of SiC particles on the friction and wear behavior of Ti3Si(Al)C2-based composites. Wear 262:826–832

Acknowledgements

The authors would like to express heartfelt thanks to Department of Mechanical engineering, Cape Peninsula University of Technology, South Africa for providing the experimental setup and their corresponding labs for supporting this work.

Author information

Authors and Affiliations

Contributions

Abdul Wahab Hashmi: Data curation, Writing-original draft preparation.

Husain Mehdi: Paper writing, and reviewing.

Sipokazi Mabua, and Velaphi Msomi: Conceived and planned the experiments, and carried out the experiments.

Prabhujit Mohapatra: Reviewing, editing and proof reading.

Corresponding author

Ethics declarations

Conflict of Interest

Authors declare no conflict of interest.

Ethics Approval

Manuscript was prepared following the rules of good scientific practice.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hashmi, A.W., Mehdi, H., Mabuwa, S. et al. Influence of FSP Parameters on Wear and Microstructural Characterization of Dissimilar TIG Welded Joints with Si-rich Filler Metal. Silicon 14, 11131–11145 (2022). https://doi.org/10.1007/s12633-022-01848-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-01848-8