Abstract

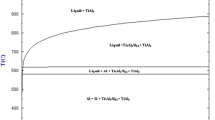

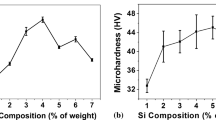

Semisolid forming is a processing technique which involves working between the semisolid temperature ranges. By powder metallurgy route, globular grains can be obtained which is a prerequisite for semisolid processing. In this work, Al-Si-Mg alloy with different Mg/Si ratios of 0.75, 1, 1.5, and 2 have been extruded and the mechanical and metallurgical properties prior and after extrusion process have been evaluated. Differential thermal analysis was used to determine the solidus and liquidus point temperatures within the range of 560 to 580 °C. Extrusion was carried out for three different temperatures namely (i) near solidus (ts), (ii) near eutectic (te), and (iii) near liquidus temperatures (tl) and three different strain rates (0.1 s−1, 0.2 s−1 and 0.3 s−1) respectively. Specimens were demarcated into three regions (head, middle, and tail) with tail region showing high hardness (65 HV) properties whereas head and middle regions displaying higher densities (90-95%). Similarly, specimens extruded at eutectic temperatures offered average density (90%) and high hardness (65 HV). Among the ratios, R=2 offered high mechanical properties. Grain size analysis revealed that R=0.75 had coarse grains (160 μm) and more spherical grains (0.9) but as the ratio increased the grain size decreased (40 μm). Deep learning technique like convolutional neural networks were used for feature prediction which predicted the 𝜶-Al grains with an accuracy of above 90%.

Similar content being viewed by others

Data Availability

As this manuscript is a part of ongoing research at this point of time data cannot be shared.

References

Mallapur DG, Udupa KR, Kori SA (2011) Studies on the influence of grain refining and modification on microstructure and mechanical properties of forged A356 alloy. Mater Sci Eng A 528:4747–4752

Lee S-L, Cheng Y-C, Chen W-C et al (2012) Effects of strontium and heat treatment on the wear-corrosion property of Al–7Si–0.3 Mg alloy. Mater Chem Phys 135:503–509

Li Q, Li F, Xia T et al (2015) Effects of in-situ γ-Al2O3 particles and heat treatment on the microstructure and mechanical properties of A356 aluminium alloy. J Alloys Compd 627:352–358

Mohamed AMA, Samuel AM, Samuel FH, Doty HW (2009) Influence of additives on the microstructure and tensile properties of near-eutectic Al–10.8% Si cast alloy. Mater Des 30:3943–3957

Haghdadi N, Zarei-Hanzaki A, Abedi HR, Sabokpa O (2012) The effect of thermomechanical parameters on the eutectic silicon characteristics in a non-modified cast A356 aluminum alloy. Mater Sci Eng A 549:93–99

Li JH, Zarif MZ, Albu M et al (2014) Nucleation kinetics of entrained eutectic Si in Al–5Si alloys. Acta Mater 72:80–98

Basavakumar KG, Mukunda PG, Chakraborty M (2008) Influence of grain refinement and modification on microstructure and mechanical properties of Al–7Si and Al–7Si–2.5 Cu cast alloys. Mater Charact 59:283–289

Jiang W, Zhu J, Li G et al (2021) Enhanced mechanical properties of 6082 aluminum alloy via SiC addition combined with squeeze casting. J Mater Sci Technol 88:119–131

Zhu J, Jiang W, Li G et al (2020) Microstructure and mechanical properties of SiCnp/Al6082 aluminum matrix composites prepared by squeeze casting combined with stir casting. J Mater Process Technol 283:116699

Li P, Liu S, Zhang L, Liu X (2013) Grain refinement of A356 alloy by Al–Ti–B–C master alloy and its effect on mechanical properties. Mater Des 47:522–528

Praveen TR, Nayaka HS, Swaroop S (2019) Influence of equal channel angular pressing and laser shock peening on fatigue behaviour of AM80 alloy. Surf Coat Technol 369:221–227

Praveen TR, Nayaka HS, Swaroop S, Gopi KR (2020) Strength enhancement of magnesium alloy through equal channel angular pressing and laser shock peening. Appl Surf Sci 512:145755

Praveen TR, Gopi KR, Nayaka HS (2018) Numerical simulation of shot peening process on equal channel angular pressed magnesium alloy. Silicon 10:2463–2472

Farahany S, Ourdjini A, Bakar TAA, Idris MH (2014) A new approach to assess the effects of Sr and Bi interaction in ADC12 Al–Si die casting alloy. Thermochim Acta 575:179–187

Ludwig TH, Dæhlen ES, Schaffer PL, Arnberg L (2014) The effect of Ca and P interaction on the Al–Si eutectic in a hypoeutectic Al–Si alloy. J Alloys Compd 586:180–190

Zhong-wei C, Wan-qi J, Rui-jie Z (2005) Superheat treatment of Al–7Si–0.55 Mg alloy melt. Mater Lett 59:2183–2185

Xu CL, Wang HY, Qiu F et al (2006) Cooling rate and microstructure of rapidly solidified Al–20 wt.% Si alloy. Mater Sci Eng A 417:275–280

McDonald SD, Nogita K, Dahle AK (2004) Eutectic nucleation in Al–Si alloys. Acta Mater 52:4273–4280

Dahle AK, Nogita K, McDonald SD et al (2005) Eutectic modification and microstructure development in Al–Si Alloys. Mater Sci Eng A 413:243–248

Jiang W, Fan Z, Dai Y, Li C (2014) Effects of rare earth elements addition on microstructures, tensile properties and fractography of A357 alloy. Mater Sci Eng A 597:237–244

Nogita K, Knuutinen A, McDonald SD, Dahle AK (2001) Mechanisms of eutectic solidification in Al–Si alloys modified with Ba, Ca, Y and Yb. J Light Met 1:219–228

Nogita K, Yasuda H, Yoshiya M et al (2010) The role of trace element segregation in the eutectic modification of hypoeutectic Al–Si alloys. J Alloys Compd 489:415–420

Sha M, Wu S, Wan L (2012) Combined effects of cobalt addition and ultrasonic vibration on microstructure and mechanical properties of hypereutectic Al–Si alloys with 0.7% Fe. Mater Sci Eng A 554:142–148

Elsebaie O, Mohamed AMA, Samuel AM et al (2011) The role of alloying additives and aging treatment on the impact behavior of 319 cast alloy. Mater Des 32:3205–3220

Vissers R, van Huis MA, Jansen J et al (2007) The crystal structure of the β′ phase in Al–Mg–Si alloys. Acta Mater 55:3815–3823

Salleh MS, Omar MZ, Syarif J (2015) The effects of Mg addition on the microstructure and mechanical properties of thixoformed Al–5% Si–Cu alloys. J Alloys Compd 621:121–130

Zedan Y, Alkahtani S (2013) Influence of the microstructure on the machinability of heat-treated Al–10.8% Si cast alloys: Role of copper-rich intermetallics. J Mater Process Technol 213:167–179

Hekmat-Ardakan A, Ajersch F (2010) Thermodynamic evaluation of hypereutectic Al–Si (A390) alloy with addition of Mg. Acta Mater 58:3422–3428

Yıldırım M, Özyürek D (2013) The effects of Mg amount on the microstructure and mechanical properties of Al–Si–Mg alloys. Mater Des 51:767–774

Thirugnanam A, Sukumaran K, Pillai UTS et al (2007) Effect of Mg on the fracture characteristics of cast Al–7Si–Mg alloys. Mater Sci Eng A 445:405–414

Mandal A, Chippa N, Jayasankar K, Mukherjee PS (2014) Effect of high magnesium content on microstructure of Al–7Si alloy. Mater Lett 117:168–170

Hekmat-Ardakan A, Ajersch F, Chen X-G (2011) Microstructure modification of Al–17% Si alloy by addition of Mg. J Mater Sci 46:2370–2378

Nafisi S, Ghomashchi R (2006) Grain refining of conventional and semi-solid A356 Al–Si alloy. J Mater Process Technol 174:371–383

Hernandez FCR, Sokolowski JH (2006) Thermal analysis and microscopical characterization of Al–Si hypereutectic alloys. J Alloys Compd 419:180–190

Xu X, Yang Z, Ye Y et al (2016) Effects of various Mg/Si ratios on microstructure and performance property of Al-Mg-Si alloy cables. Mater Charact 119:114–119

Kaushik R, Kumar S (2019) Image Segmentation Using Convolutional Neural Network. Int J Sci Technol Res 8(11):667

Sjölander E, Seifeddine S (2010) The heat treatment of Al–Si–Cu–Mg casting alloys. J Mater Process Technol 210:1249–1259

Vijeesh V, Prabhu KN (2014) Computer aided cooling curve analysis and microstructure of cerium added hypereutectic Al–Si (LM29) alloy. Trans Indian Inst Met 67:541–549

Nafisi S, Emadi D, Ghomashchi R (2008) Impact of Mg addition on solidification behaviour of Al–7% Si alloy. Mater Sci Technol 24:718–724

Gupta AK, Lloyd DJ, Court SA (2001) Precipitation hardening in Al–Mg–Si alloys with and without excess Si. Mater Sci Eng A 316:11–17

Kim BJ, Jung SS, Hwang JH et al (2019) Effect of eutectic Mg2Si phase modification on the mechanical properties of Al-8Zn-6Si-4Mg-2Cu cast alloy. Metals (Basel) 9:32

Caceres CH, Davidson CJ, Griffiths JR, Wang QG (1999) The effect of Mg on the microstructure and mechanical behavior of Al-Si-Mg casting alloys. Metall Mater Trans A 30:2611–2618

Baradarani B, Raiszadeh R (2011) Precipitation hardening of cast Zr-containing A356 aluminium alloy. Mater Des 32:935–940

Donati L, Dzwonczyk JS, Zhou J, Tomesani L (2008) Microstructure prediction of hot-deformed aluminium alloys. Key Engineering Materials. Trans Tech Publ, pp 107–116

Li Q, Li B, Li J et al (2017) Effects of the addition of Mg on the microstructure and mechanical properties of hypoeutectic Al–7% Si alloy. Int J Met 11:823–830

Yamamoto K, Takahashi M, Kamikubo Y et al (2020) Effect of Mg content on age-hardening response, tensile properties, and microstructures of a T5-treated thixo-cast hypoeutectic Al–Si alloy. Mater Sci Eng A 798:140089

Mirzadeh H, Najafizadeh A (2010) Prediction of the critical conditions for initiation of dynamic recrystallization. Mater Des 31:1174–1179

Mongkhonthanaphon S, Limpiyakorn Y (2019) Classification of titanium microstructure with fully convolutional neural networks. In: Journal of Physics: Conference Series. IOP Publishing, p 12022

Acknowledgements

The authors are grateful to the Director of National Institute of Technology-Warangal, faculty members and laboratory staff of Mechanical Engineering Department as well as Metallurgical and Materials Engineering Department for their support throughout the completion of this work.

Author information

Authors and Affiliations

Contributions

M. J. Davidson: Conceptualization, Methodology, Editing, C. S. P Rao: Editing, Supervision, Abeyram M Nithin: Experimentation and characterization.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Conflict of Interest

All authors declare that they have no competing interests.

Conflict of Interest

All authors declare that there is no conflict of interest.

Research Involving Human Participants and/or Animals

Not applicable.

Consent for Publication

Yes.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nithin, A.M., Davidson, M.J. & Rao, C.S.P. Effect of Various Mg/Si Ratios on Microstructure and Structural Properties of Thixoextruded Al-Si-Mg Alloys. Silicon 14, 11675–11686 (2022). https://doi.org/10.1007/s12633-022-01689-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-01689-5