Abstract

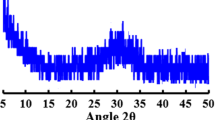

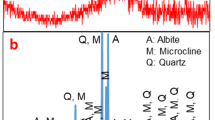

This paper investigates the resistance of alkali-activated binder from volcanic ash (VA) + Municipal Solid Waste Incinerator Fly Ash (MSWI-FA) system exposed into sulphuric acid solution and artificial seawater at 56 days. The effect of these aggressive media on the physical, structural, mechanical and microstructural properties of alkali-activated mortars was discussed. The degradation was studied using X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR) and scanning electron microscopy (SEM). The decrease of compressive strength after 56 days was 9.10%, 22.08%, 32.5% in artificial seawater, 2% H2SO4 and 4% H2SO4, respectively. The loss of strength in both media is primarily due to the fact that the water molecules present in these media penetrated into the pore cavities between binders and aggregates, making them weak. In an acidic medium, it is also due to the decalcification and depolymerization reactions whereas in seawater medium, it is attributed to the movement of content ions and probable formation of Friedel’s salt. The results disclose that VA + MSWI-FA based alkali activated materials resist better in seawater than in sulphuric acid solution. Synergistic use of volcanic ash and MSWI-FA for construction materials through alkaline activation looks like the upcoming trend to valorize these wastes.

Graphical abstract

Similar content being viewed by others

References

Hajimohammadi A, Deventer JSJ (2017) Characterisation of one-Part Geopolymer binders made from Fly. Waste Biomass Valorization 8:225–233. https://doi.org/10.1007/s12649-016-9582-5

Galiano YL, Arenas CLC, Vilches FAL (2017) Behaviour of Fly ash-based Geopolymer panels under fire. Waste Biomass Valorization 8:2485–2494. https://doi.org/10.1007/s12649-016-9803-y

Luukkonen T, Abdollahnejad Z, Yliniemi J, Kinnunen P, Illikainen M (2018) One-part alkali-activated materials: a review. Cem Concr Res 103:21–34. https://doi.org/10.1016/j.cemconres.2017.10.001

Lancellotti I, Kamseu E, Michelazzi M, Barbieri L, Corradi A, Leonelli C (2010) Chemical stability of geopolymers containing municipal solid waste incinerator fly ash. Waste Manag 30:673–679. https://doi.org/10.1016/j.wasman.2009.09.032

Ferone C, Colangelo F, Messina F, Santoro L, Cioffi R (2013) Recycling of pre-washed municipal solid waste incinerator fly ash in the manufacturing of low temperature setting geopolymer materials. Materials (Basel) 6:3420–3437. https://doi.org/10.3390/ma6083420

Tome S, Etoh M, Etame J, Sanjay K (2018) Characterization and Leachability Behaviour of Geopolymer Cement Synthesised from Municipal Solid Waste Incinerator Fly Ash and Volcanic Ash Blends. Recyling. https://doi.org/10.3390/recycling3040050

Kumar A, Kumar S (2013) Development of paving blocks from synergistic use of red mud and fly ash using geopolymerization. Constr Build Mater 38:865–871. https://doi.org/10.1016/j.conbuildmat.2012.09.013

Kaze CR, Alomayri T, Hasan A, Tome S, Lecomte-Nana GL, Nemaleu JGD, Tchakoute HK, Kamseu E, Melo UC, Rahier H (2020) Reaction kinetics and rheological behaviour of meta-halloysite based geopolymer cured at room temperature: effect of thermal activation on physicochemical and microstructural properties. Appl Clay Sci 196:105773. https://doi.org/10.1016/j.clay.2020.105773

Noël J, Djobo Y, Elimbi A, Tchakouté HK (2017) Volcanic ash-based geopolymer cements / concretes : the current state of the art and perspectives. 4433–4446. https://doi.org/10.1007/s11356-016-8230-8

Kouamo Tchakoute H, Elimbi A, Diffo Kenne BB, Mbey JA, Njopwouo D (2013) Synthesis of geopolymers from volcanic ash via the alkaline fusion method: effect of Al2O3/Na2O molar ratio of soda–volcanic ash. Ceram Int 39:269–276. https://doi.org/10.1016/j.ceramint.2012.06.021

Jean Noel Yankwa Djobo J, Kumar S, Elimbi A (2016) Reactivity of volcanic ash in alkaline medium , microstructural and strength characteristics of resulting geopolymers under different synthesis conditions. https://doi.org/10.1007/s10853-016-0257-1

Yankwa Djobo JN, Elimbi A, Tchakouté HK, Kumar S (2016) Mechanical activation of volcanic ash for geopolymer synthesis: effect on reaction kinetics, gel characteristics, physical and mechanical properties. RSC Adv 6:39106–39117. https://doi.org/10.1039/C6RA03667H

Tome S, , Etoh M-A, Etame J, Sanjay K (2019) Improved reactivity of volcanic ash using municipal solid incinerator Fly ash for alkali-activated cement synthesis. Waste Biomass Valorization 0:0. https://doi.org/10.1007/s12649-019-00604-1, 11, 3035, 3044

Afshar A, Jahandari S, Rasekh H, Shariati M, Afshar A, Shokrgozar A (2020) Corrosion resistance evaluation of rebars with various primers and coatings in concrete modified with different additives. Constr Build Mater 262:120034. https://doi.org/10.1016/j.conbuildmat.2020.120034

Sadeghian F, Haddad A, Jahandari S, Rasekh H, Ozbakkaloglu T (2020) Effects of electrokinetic phenomena on the load-bearing capacity of different steel and concrete piles: a small-scale experimental study. Can Geotech J:1–16. https://doi.org/10.1139/cgj-2019-0650

Yankwa Djobo JN, Elimbi A, Kouamo Tchakouté H, Kumar S (2016) Mechanical properties and durability of volcanic ash based geopolymer mortars. Constr Build Mater 124:606–614. https://doi.org/10.1016/j.conbuildmat.2016.07.141

Bakharev T (2005) Resistance of geopolymer materials to acid attack. Cem Concr Res 35:658–670. https://doi.org/10.1016/j.cemconres.2004.06.005

Gopalakrishnan R, Raju KC (2016) Durability of alkali activated concrete-a review Department of Civil Engineering. Sri Venkateswara College Eng 7:18–26. https://doi.org/10.5829/idosi.weasj.2016.7.1.22541

Yip CK, Lukey GC, van Deventer JSJ (2005) The coexistence of geopolymeric gel and calcium silicate hydrate at the early stage of alkaline activation. Cem Concr Res 35:1688–1697. https://doi.org/10.1016/j.cemconres.2004.10.042

Part WK, Ramli M, Cheah CB (2016) An overview on the influence of various factors on the properties of Geopolymer concrete derived from industrial byproducts. Handb Low Carbon Concr 77:263–334. https://doi.org/10.1016/B978-0-12-804524-4.00011-7

Sara banu J, Kumutha R, Vijai K (2017) A Review on Durability Studies of Geopolymer Concrete and Mortar under Aggressive Environment. Int J Civ Eng 4:32–35. https://doi.org/10.14445/23488352/ijce-v4i5p108

HiMedia™ Laboratories (2013). Artificial Sea Water Salts Broth M1942:1–2

Jahandari S, Saberian M, Tao Z, Mojtahedi SF, Li J, Ghasemi M, Rezvani SS, Li W (2019) Cold Regions Science and Technology E ff ects of saturation degrees , freezing-thawing , and curing on geotechnical properties of lime and lime-cement concretes. Cold Reg Sci Technol 160:242–251. https://doi.org/10.1016/j.coldregions.2019.02.011

Saberian M, Jahandari S, Li J, Zivari F (2017) Effect of curing , capillary action , and groundwater level increment on geotechnical properties of lime concrete : Experimental and prediction studies. J Rock Mech Geotech Eng 9:638–647. https://doi.org/10.1016/j.jrmge.2017.01.004

Kazemi M, Hajforoush M, Talebi PK, Daneshfar M, Shokrgozar A, Jahandari S, Saberian M, Li J (2020) In-situ strength estimation of polypropylene fibre reinforced recycled aggregate concrete using Schmidt rebound hammer and point load test. J Sustain Cem Mater 0:1–18. https://doi.org/10.1080/21650373.2020.1734983, 9

Walkley B, San Nicolas R, Sani MA, Bernal SA, van Deventer JSJ, Provis JL (2017) Structural evolution of synthetic alkali-activated CaO-MgO-Na2O-Al2O3-SiO2materials is influenced by mg content. Cem Concr Res 99:155–171. https://doi.org/10.1016/j.cemconres.2017.05.006

Amilton JAPH, Rantley SULB, Antano CAGP et al (2001) Dissolution of nepheline , jadeite and albite glasses : Toward better models for aluminosilicate dissolution. Geochimica et Cosmochimica Acta 65:3683–3702

Kaze CR, Yankwa JN, Nana A et al (2018) Effect of silicate modulus on the setting, mechanical strength and microstructure of iron-rich aluminosilicate (laterite) based-geopolymer cured at room temperature. Ceram Int 44:21442–21450. https://doi.org/10.1016/j.ceramint.2018.08.205

Bakharev T (2005) Resistance of geopolymer materials to acid attack. Cem Concr Res 35:658–670. https://doi.org/10.1016/j.cemconres.2004.06.005

Ma CK, Awang AZ, Omar W (2018) Structural and material performance of geopolymer concrete: a review. Constr Build Mater 186:90–102

Glasser FP, Kindness A, Stronach SA (1999) Stability and solubility relationships in AFm phases. Part I. chloride, sulfate and hydroxide. Cem Concr Res 29:861–866. https://doi.org/10.1016/S0008-8846(99)00055-1

Acknowledgments

The work presented in the paper has been carried out under CSIR-TWAS Sandwich Postgraduate Fellowship Award FR No 3240293597 and is greatly acknowledged. The authors are also grateful to Director, CSIR-National Metallurgical Laboratory, Jamshedpur, India for extending all the facility to carry out this research.

Availability of Data and Material

All data generated or analysed during this study are included in this article.

Funding

This study was funded by CSIR-TWAS Posgraduate Fellowship (grant number: 3440193597).

Author information

Authors and Affiliations

Contributions

Sylvain Tome: Conceptualization, Methodology, Investigation, writing - original draft, resources. Achile Nana: Writing - review & editing. Cyriaque Rodrique Kaze: Writing - review & editing. Thamer Salman Alomayri: Writing - review & editing. Jean Noel Y. Djobo: Writing - review & editing. Elie Kamseu: Writing - review & editing. Marie-Anne Etoh: Writing - review & editing. Jacques Etame: Writing - review & editing. Sanjay Kumar: Conceptualization, Methodology, Writing - review & editing.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Code Availability

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• VA+MSWI-FA based alkali activated materials resist better in seawater than in sulphuric acid solution

• The loss of strength in acid medium is due to the decalcification and depolymerization reactions

• The calcium sulphate is the new mineral forms in acidic medium

Rights and permissions

About this article

Cite this article

Tome, S., Nana, A., Kaze, C.R. et al. Resistance of Alkali-Activated Blended Volcanic Ash-MSWI-FA Mortar in Sulphuric Acid and Artificial Seawater. Silicon 14, 2687–2694 (2022). https://doi.org/10.1007/s12633-021-01055-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01055-x