Abstract

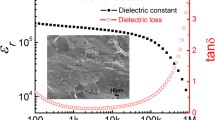

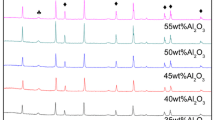

Hybrid ceramic (SiO2-Si3N4-Al2O3) composites were prepared by gel casting process, a near net shape technique. The effects of solid loading and monomers ratio on flexural strength, porosity, room temperature dielectric properties and thermal conductivity were investigated. Methylacrylamide (MAM) and N, N1- methylenebisacrylamide (MBAM) were used as monomers because of their low toxicity. The hybrid ceramics were sintered to a temperature of 1250 °C and the monomer content kept constant at 10 wt%. The flexural strength of the ceramics increases and porosity decreases with increase in solid loading. The flexural strength increases up to a certain stage and then decreases by showing an optimum point at monomer ratio of 10:1. The maximum flexural strength and minimum porosity obtained were 95.12 MPa, and 28.5% respectively. The dielectric constant and dielectric loss were increased slightly by the addition of Si3N4-Al2O3 and found to be 4.822 and 0.00351 at a frequency of 30 MHz at room temperature. The minimum thermal conductivity at room temperature of the composite was found to be 0.2131 W/mK.

Similar content being viewed by others

References

Mishra S et al (2010) Structure–property correlation in cellular silica processed through hydrophobized fused silica powder for aerospace application. J Alloys Compd 504:76–82

Wan W et al (2013) Gelcasting of fused silica glass using a low-toxicity monomer DMAA. J Non-Cryst Solids 79:229–234

Wan W et al (2014) Effect of solid loading on gelcasting of silica ceramics using DMAA. Ceram Int 40:1735–1740

Du H et al (2010) Effect of temperature on dielectric properties of Si3N4/SiO2 composite and silica ceramic. J Alloys Compd 503:L9–L13

Kandi KK et al (2016) Effect of monomers content and their ratio on Gelcasting of fused silica. T Indian Ceram Soc 75(3):1–4

Yu Z et al (2006) Use of HEMA in Gelcasting of ceramics: a case study on fused silica. J Am Ceram Soc 89(9):2933–2935

Yichen H et al (2008) Study on the gel casting of fused silica glass. J Non-Cryst Solids 354:1285–1289

Jia D et al (2011) Effect of preforming process and starting fused SiO particle size on microstructure and mechanical properties of Pressurelessly sintered BN/SiO ceramic composites. J Am Ceram Soc 94(10):3552–3560

Wan W et al (2016) Effect of trace alumina on mechanical, dielectric, and ablation properties of fused silica ceramics. J Alloys Compd 675:64–72

Chen B et al (2014) Preparation and properties of reduced graphene oxide/fused silica composites. Carbon 77:66–75

Wen G et al (2000) Co-enhanced SiO2-BN ceramics for high-temperature dielectric applications. J Eur Ceram Soc 20:1923–1928

Yu J et al (2009) Neural network modeling and analysis of gel casting preparation. Ceram Int 35:2943–2950

Wilson PJ et al (2011) The effect of alumina contamination from the ball-milling of fused silica on the high temperature properties of injection moulded silica ceramic components. J Eur Ceram Soc 31:977–981

Kandi KK et al (2016) Effect of dispersant on the rheological properties of gelcast fused silica ceramics. IOP Conf Ser Mater Sci Eng 149:012063

Gong L et al (2013) Thermal conductivity of highly porous mullite material. Int J Heat Mass Transf 67:253–259

Cernuschi F et al (2004) Modelling of thermal conductivity of porous materials: application to thick thermal barrier coatings. J Eur Ceram Soc 24:2657–2667

Lin K-L et al (2013) Water absorption and retention of porous ceramics co-sintered from waste diatomite and catalyst. Environ Prog Sustain Energy 32(3):640–648

Shi C, Zhu Y, Qian H, Lu L (2014) Fabrication of silicon nitride fiber–PMMA composite through free radical polymerization in batch. Mater Res Bull 51:161–166

Leyva-Ramos R et al (2008) Fluoride removal from water solution by adsorption on activated alumina prepared from pseudo-boehmite. J Environ Eng Manage 18(5):301–309

Zhang QF et al (2013) Large electric field-induced strain near AFE/FE phase boundary in (Pb0.97 La0.02) (Zr, Sn, Ti)O3 system. J Mater Sci 48:6218–6222

Wan W, Feng Y, Yang J, Bu W, Qiu T (2016) Microstructure, mechanical and high-temperature dielectric properties of zirconia-reinforced fused silica ceramics. Ceram Int 42:6436–6443

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Punugupati, G., Bose, P.S.C., Raghavendra, G. et al. Influence of Solid Loading and Ratio of Monomers on Mechanical and Dielectric Properties of Hybrid Ceramic Composites. Silicon 11, 2701–2710 (2019). https://doi.org/10.1007/s12633-018-0061-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-018-0061-4