Abstract

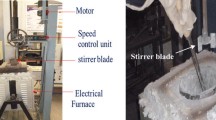

The current study investigates the tribological behaviour of aluminium hybrid composite reinforced with SiC and MoS2 at various temperature environments. The hybrid metal matrix composites have been fabricated through compo casting method by reinforcing different sizes of SiC (10, 20, 40 μm) at various weight fractions (5%, 10% & 15%) with 5059 aluminium alloy, meanwhile the addition of Molybdenum disulphide (MoS2) is fixed at 2%. Tribological behaviour of composites was evaluated based on wear loss and friction coefficient by using pin on disc apparatus. Along with particle size and weight percentage of SiC, load, sliding velocity, sliding distance and temperature were considered as process parameters and L27 orthogonal array was selected to perform the experiments. Through Taguchi and Analysis of Variance (ANOVA) method optimum sliding condition for reduced wear loss and the significance of each parameter on wear behaviour of the composite were identified. Temperature and load predominantly affects the tribological behaviour of aluminium hybrid composite. It was found that the wear resistance is high when smaller particles were reinforced at maximum percentage (15%) and the results were supported with worn surface SEM images.

Similar content being viewed by others

References

Suresh S, Mortensen A (1993) Fundamentals of metal matrix composites. Butterworth-Heinemann, Oxford

Rittner M (2000) Metal matrix composites in the 21st century: markets and opportunities. BCC Inc, Norwalk

Sudarshan, Surappa MK (2008) Dry sliding wear of fly ash particle reinforced A356 Al composites. Wear 265:349–360

Ghosh S, Sahoo P, Sutradhar G (2012) Wear behaviour of Al-SiCP metal matrix composites and optimization using taguchi method and grey relational analysis. J Miner Mater Charact Eng 11:1085–1094

Rao RN, Das S (2011) Effect of applied pressure on the tribological behaviour of SiCp reinforced AA2024 alloy. Tribol Int 44:454–462

Sahin Y (2003) Preparation and some properties of SiC particle reinforced aluminium alloy composites. Mater Des 24:671–679

Ghosh S, Sahoo P, Sutradhar G (2013) Tribological performance optimization of Al-7.5% SiCp composites using taguchi method and grey relation analysis. J Comps:1–9

Mandal D, Viswanathan S (2013) Effect of re-melting on particle distribution and interface formation in SiC reinforced 2124Al matrix composite. Mater Charact 86:21–27

Shorowordi KM, Laoui T, Haseeb ASMA, Celis JP, Froyen L (2003) Microstructure and interface characteristics of B4C, SiC and Al2 O 3 reinforced Al matrix composites: A comparative study. J Mater Process Technol 142:738–743

Mindivan H (2010) Reciprocal sliding wear behaviour of B4C particulate reinforced aluminum alloy composites. Mater Lett 64:405–407

Poria S, Sahoo P, Sutradha G (2016) Tribological characterization of stir-cast aluminium-TiB2 metal matrix composites. Silicon 8(4):591–599

Wang H, Li G, Zhao Y, Chen G (2010) In situ fabrication and microstructure of Al2 O 3 particles reinforced aluminum matrix composites. Mater Sci Eng A 527:2881–2885

Naveen Kumar G, Narayanasamy R, Natarajan S, Kumaresh Babu SP, Sivaprasad K, Sivasankaran S (2010) Dry sliding wear behaviour of AA 6351-ZrB2 in situ composite at room temperature. Mater Des 31:1526–1532

Nukami T, Flemings MC (1995) In situ synthesis of TiC particulate-reinforced aluminum matrix composites. Metal Mater Trans A 26(7):1877–1884

Prakash KS, Moorthy RS, Gopal PM, Kavimani V (2016) Effect of reinforcement, compact pressure and hard ceramic coating on aluminium rock dust composite performance. Int J Refract Metals Hard Mater 54:223–229

Suresha S, Sridhara BK (2010) Wear characteristics of hybrid aluminium matrix composites reinforced with graphite and silicon carbide particulates. Key Eng Mater 70:1652–1659

Rohatgi PK (1993) Metal matrix composites. Def Sci J 43(4):323–349

Nami H, Adgi H, Sharifitabar M, Shamabadi H (2011) Microstructure and mechanical properties of friction stir welded Al/Mg2Si metal matrix cast composite. Mater Des 32:976–983

Michael Rajan HB, Ramabalan S, Dinaharan I, Vijay SJ (2014) Effect of TiB2 content and temperature on sliding wear behavior of AA7075/TiB2 in situ aluminium cast composites. Arch Civil Mech Eng 14:72–79

Natarajan S, Narayansamy R, Kumaresh Babu SP, Dinesh G, Anil Kumar B, Sivaprasad K (2009) Sliding wear behavior of Al 6063/TiB2 in situ composites at elevated temperatures. Mater Des 30:2521–2531

Baradeswaran A, Elaya Perumal A, Davim JP (2013) Effect of B4C on mechanical properties and tribological behaviour of AA6061- B4C composites. J Balkan Tribol Assoc 19(2):239–248

Basavarajappa S, Chandramohan G, Davim JP (2007) Application of Taguchi techniques to study dry sliding wear behaviour of metal matrix composites. Mater Des 28(4):1393–1398

Bezzazi M, Khamlichi A, Jabbouri A, Reis P, Davim JP (2007) Experimental characterization of frictional behavior of clutch facings using pin-on-disk machine. Mater Des 28(7):2148–2153

Narayanasamy P, Selvakumar N, Balasundar P (2015) Effect of hybridizing MoS2 on the tribological behaviour of Mg–TiC composites. Trans Indian Inst Met 68(5):911–925

Davim JP (2010) Tribology of composite materials. NOVA Publishers, New York

Davim JP (ed) (2013) Tribology of nanocomposites. Springer, Heidelberg

Nami H, Adgi H, Sharifitabar M, Shamabadi H (2011) Microstructure and mechanical properties of friction stir welded Al/Mg2/Si metal matrix cast composite. Mater Des 32:976–983

Sharifitabar M, Sarani A, Khorshahian S, Sharfiee Afarani M (2011) Fabrication of 5052Al/Al2O3 nanoceramic particle reinforced composite via friction stir processing route. Mater Des 32:4164–4172

Unlu BS (2008) Investigation of tribological and mechanical properties Al2 O 3–SiC reinforced Al composites manufactured by casting or Powder methodology method. Mater Des 29:2002–2008

Yang X (2007) Ultrasonic cavitation based nonmanufacturing of bulk aluminum matrix nano composites. J Manuf Sci Eng 129:497–501

Suresh S, Moorthi NS, Vettivel SC, Selvakumar N (2014) Effect of graphite addition on mechanical behavior of Al6061/TiB2 hybrid composite using acoustic emission. Mater Sci Eng A 612:16–27

Huseyin S, Can Kurnaz S (2006) Properties of alumina particulate reinforced aluminum alloy produced by pressure die casting. Mat Des 27(8):676–683

Gologlu C, Sakarya N (2008) The effects of cutter path strategies on surface roughness of pocket milling of 1.2738 steel based on Taguchi method. J Mater Process Technol 206(1-3):7–15

Prabhudev MS, Auradi V, Venkateswarlu K, Kori SA (2016) Influence of combined addition of boron and strontium on high temperature wear behaviour of A356 alloy. Tribol Trans 59:1–7

Stojanovic B, Babic M, Velickovic S, Blagojevic J (2016) Tribological behavior of aluminum hybridcomposites studied by application of factorial techniques. Tribol Trans 59:522–529

Fu YF, Li J, Zhang FQ, Xu K (2016) The preparation and the friction and wear behaviours of TiO2/CNT/PI composite film. J Exp Nanosci 11(6):459–469

Yigezu BS, Jha PK, Mahapatra MM (2013) Effect of sliding distance, applied load, and weight percentage of reinforcement on the abrasive wear properties of in situ synthesized Al–12% Si/TiC composites. Tribol Trans 56 (4):546– 554

Gopal PM, Prakash KS, Nagaraja S, Aravinth K (2017) Effect of weight fraction and particle size of CRT glass on the tribological behaviour of Mg-CRT-BN hybrid composites. Tribol Int 116:338–380

Nuruzzaman DM, Chowdhury MA (2012) Effect of load and sliding velocity on friction coefficient of aluminum sliding against different pin materials. AM J Mat Sci 2(1):26–31

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Daniel, S.A.A., M., S., P. M., G. et al. Study on Tribological Behaviour of Al/SiC/MoS2 Hybrid Metal Matrix Composites in High Temperature Environmental Condition. Silicon 10, 2129–2139 (2018). https://doi.org/10.1007/s12633-017-9739-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-017-9739-2