Abstract

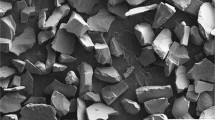

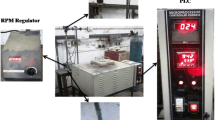

In this paper, conventional simple methods of producing MMC with attained properties through the dispersion of silicon carbide in the matrix are investigated. To achieve these objectives a two-step mixing method of stir casting technique was employed. Aluminum (99.66 %C.P) and SiC (320 and 1200 grits) were chosen as matrix and reinforcement materials respectively. Experiments were conducted by varying the weight fraction of SiC for 2.5 %, 5.0 %, 7.5 % and 10 %. The result indicated that the stir casting method was quite successful to obtain uniform dispersion of reinforcement in the matrix. This was evident by the improvement of properties of composites over the base metal. Reinforced Aluminum Silicon Carbide (ASC) showed an increase in Young’s modulus (E) and hardness above the unreinforced case and marginal reduction of electrical conductivity was recorded for the composites. The silicon carbide of 1200 grits (3 μm) showed increased Young’s modulus (E) and hardness of 1517.6 Mpa and 26.1 Hv values at 7.5% volume fraction silicon carbide; when compared with the silicon carbide 320 grit (29 μm). Also; the electrical conductivity properties of the two grit sizes of the silicon carbides were less than the base metal for all the volume fractions of silicon carbide.

Similar content being viewed by others

References

Babalola PO, Bolu CA, Inegbenebor AO, Odunfa KM (2014) Development of aluminum matrix composites- A review, Online International Journal of Engineering and Technology Research, 2014.2, 1-11, ISSN 2346452

Singla M, Dwivedi DD, Singh L, Chawla V (2009) Development of Aluminum based Silicon Carbide Particulate Metal Matrix Composite. J Miner Mater Charact Eng 8(6):455–467

Olivier B (2001) Metal Matrix Composites (MMCs) from Space to Earth.EiggenossischeMaterialprufungs-und Forschungsanstalt, EMPA, Abt. Werkstofftechnologie, Feuerwerkerstrasse 39, CH-3602 Thun. Retrieved from http://www.empa.ch/abt126 on Oct.10, 2013

Luan BF, Hansen N, Godfrey A, Wu GH, Liu Q (2011) High strength Al–Al 2O3p composites. Optim Extrusion Parameters Mater Des 32:3810–3817

kumar B, Murugan N (2012) Metallurgical and Mechanical Characterization of Stir Cast AA6061-t6-AINp Composite. Mater Des 40:52–58

Richard AMA, Fennessy K, Hay RA (1998) Aluminum Silicon Carbide (AlSiC) for Advanced Microelectronic Packages, Ceramic Process Systems, Corp. Charttey, MA 02712

BalasivanandhaPrabu. S., Karunamoorthy L, Kathiresan S, Mohan B (2006) Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite. J Mater Process Technol 171:268–273

Hashim J, Looney L, Hashmi MSJ (1999) Metal matrix composites, production by the stir casting method. J Mater Process Technol 92/93:1–7

Surappa. M. K., Surappa (1997) J Mater Process Technol 63:325–333

Skibo DM, Schuster DM, Jolla L (1988) Process for preparation of composite materials containing nonmetallic particles in a metallic matrix, and composite materials made by U.S patent. No. 4786467

Law E, Pang SD, Quek ST (2011) Discrete dislocation analysis of the mechanical reponse of silicon carbide reinforced aluminum nanocomposite. Composites, part B 42:92–98

Smallman RE, Bishop RJ (1999) Modern physical metallurgy and materials engineering- science, process, applications (6th ed.) Butterworth Heinemann, Jordan Hill, Oxford

Inegbenebor AO, Bolu CA, Babalola PO, Inegbenebor AI, Fayomi OS (2015) Influence of the Grit size of Silicon Carbide Particles on the Mechanical and Electrical properties of Stir Casting Aluminum Matrix Composite Material. J Silicon 1(3). doi:10.1007/ss12633=015-9305-8

Babalola PO, Inegbenebor AO, Bolu CA, Inegbenebor AI (2015) The development of Molecular based Materials for Electrical and Electronic Application. J Miner, Met Miner Soc (TMS) 67(4):830–834

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Inegbenebor, A.O., Bolu, C.A., Babalola, P.O. et al. Aluminum Silicon Carbide Particulate Metal Matrix Composite Development Via Stir Casting Processing. Silicon 10, 343–347 (2018). https://doi.org/10.1007/s12633-016-9451-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-016-9451-7