Abstract

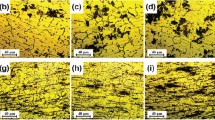

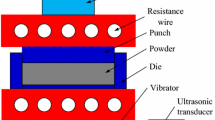

A low-alloyed Mg−2Zn−0.8Sr−0.2Ca matrix composite reinforced by TiC nano-particles was successfully prepared by semi-solid stirring under the assistance of ultrasonic, and then the as-cast composite was hot extruded. The results indicated that the volume fraction of dynamical recrystallization and the recrystallized grain size have a certain decline at lower extrusion temperature or rate. The finest grain size of ∼0.30 µm is obtained in the sample extruded at 200°C and 0.1 mm/s. The as-extruded sample displays a strong basal texture intensity, and the basal texture intensity increases to 5.937 mud while the extrusion temperature increases from 200 to 240°C. The ultra-high mechanical properties (ultimate tensile strength of 480.2 MPa, yield strength of 462 MPa) are obtained after extrusion at 200°C with a rate of 0.1 mm/s. Among all strengthening mechanisms for the present composite, the grain refinement contributes the most to the increase in strength. A mixture of cleavage facets and dimples were observed in the fracture surfaces of three as-extruded nanocomposites, which explain a mix of brittle-ductile fracture way of the samples.

Similar content being viewed by others

References

J.F. Song, J. She, D.L. Chen, and F.S. Pan, Latest research advances on magnesium and magnesium alloys worldwide, J. Magnes. Alloys, 8(2020), No. 1, p. 1.

H.C. Pan, R. Kang, J.R. Li, H.B. Xie, Z.R. Zeng, Q.Y. Huang, C.L. Yang, Y.P. Ren, and G.W. Qin, Mechanistic investigation of a low-alloy Mg−Ca-based extrusion alloy with high strength-ductility synergy, Acta Mater., 186(2020), p. 278.

X.J. Wang, D.K. Xu, R.Z. Wu, X.B. Chen, Q.M. Peng, L. Jin, Y.C. Xin, Z.Q. Zhang, Y. Liu, X.H. Chen, G. Chen, K.K. Deng, and H.Y. Wang, What is going on in magnesium alloys?, J. Mater. Sci. Technol., 34(2018), No. 2, p. 245.

G.Z. Kang and H. Li, Review on cyclic plasticity of magnesium alloys: Experiments and constitutive models, Int. J. Miner. Metall. Mater., 28(2021), No. 4, p. 567.

M. Shahin, K. Munir, C.E. Wen, and Y.C. Li, Magnesium matrix nanocomposites for orthopedic applications: A review from mechanical, corrosion, and biological perspectives, Acta Biomater., 96(2019), p. 1.

K.B. Nie, Z.H. Zhu, P. Munroe, K.K. Deng, and J.G. Han, Effect of extrusion speed on mixed grain microstructure and tensile properties of a Mg−2.9Zn−1.1Ca−0.5Mn nanocomposite reinforced by a low mass fraction of TiCp, Mater. Sci. Eng. A, 796(2020), art. No. 140223.

H.Y. Jeong, B. Kim, S.G. Kim, H.J. Kim, and S.S. Park, Effect of Ce addition on the microstructure and tensile properties of extruded Mg−Zn−Zr alloys, Mater. Sci. Eng. A, 612(2014), p. 217.

C.J. Bettles, M.A. Gibson, and K. Venkatesan, Enhanced age-hardening behaviour in Mg−4 wt.% Zn micro-alloyed with Ca, Scripta Mater., 51(2004), No. 3, p. 193.

R. Alizadeh, J.Y. Wang, and J. LLorca, Precipitate strengthening of pyramidal slip in Mg−Zn alloys, Mater. Sci. Eng. A, 804(2021), art. No. 140697.

T. Nakata, T. Mezaki, R. Ajima, C. Xu, K. Oh-Ishi, K. Shimizu, S. Hanaki, T.T. Sasaki, K. Hono, and S. Kamado, High-speed extrusion of heat-treatable Mg−Al−Ca−Mn dilute alloy, Scripta Mater., 101(2015), p. 28.

X. Meng, Z.T. Jiang, S.J. Zhu, and S.K. Guan, Effects of Sr addition on microstructure, mechanical and corrosion properties of biodegradable Mg−Zn−Ca alloy, J. Alloys Compd., 838(2020), art. No. 155611.

J.Y. Wang, Y.W. Chen, Z. Chen, J. Llorca, and X.Q. Zeng, Deformation mechanisms of Mg-Ca-Zn alloys studied by means of micropillar compression tests, Acta Mater., 217(2021), art. No. 117151.

Y. Liu, N. Li, M. Arul Kumar, S. Pathak, J. Wang, R.J. McCabe, N.A. Mara, and C.N. Tomé, Experimentally quantifying critical stresses associated with basal slip and twinning in magnesium using micropillars, Acta Mater., 135(2017), p. 411.

X.F. Sun, C.J. Wang, K.K. Deng, K.B. Nie, X.C. Zhang, and X.Y. Xiao, High strength SiCp/AZ91 composite assisted by dynamic precipitated Mg17Al12 phase, J. Alloys Compd., 732(2018), p. 328.

K.K. Deng, J.Y. Shi, C.J. Wang, X.J. Wang, Y.W. Wu, K.B. Nie, and K. Wu, Microstructure and strengthening mechanism of bimodal size particle reinforced magnesium matrix composite, Compos. A: Appl. Sci. Manuf., 43(2012), No. 8, p. 1280.

K.B. Nie, X.J. Wang, K.K. Deng, X.S. Hu, and K. Wu, Magnesium matrix composite reinforced by nanoparticles — A review, J. Magnes. Alloys, 9(2021), No. 1, p. 57.

C.P. Li, Z.G. Wang, H.Y. Wang, X. Zhu, M. Wu, and Q.C. Jiang, Fabrication of nano-SiC particulate reinforced Mg-8Al-1Sn composites by powder metallurgy combined with hot extrusion, J. Mater. Eng. Perform., 25(2016), No. 11, p. 5049.

H. Yu, H.P. Zhou, Y. Sun, L.L. Ren, Z.P. Wan, and L.X. Hu, Microstructures and mechanical properties of ultrafine-grained Ti/AZ31 magnesium matrix composite prepared by powder metallurgy, Adv. Powder Technol., 29(2018), No. 12, p. 3241.

G.K. Meenashisundaram and M. Gupta, Low volume fraction nano-titanium particulates for improving the mechanical response of pure magnesium, J. Alloys Compd., 593(2014), p. 176.

X.J. Wang, K. Wu, H.F. Zhang, W.X. Huang, H. Chang, W.M. Gan, M.Y. Zheng, and D.L. Peng, Effect of hot extrusion on the microstructure of a particulate reinforced magnesium matrix composite, Mater. Sci. Eng. A, 465(2007), No. 1–2, p. 78.

Y.C. Guo, K.B. Nie, X.K. Kang, K.K. Deng, J.G. Han, and Z.H. Zhu, Achieving high-strength magnesium matrix nanocomposite through synergistical effect of external hybrid (SiC+TiC) nanoparticles and dynamic precipitated phase, J. Alloys Compd., 771(2019), p. 847.

F. Samadpour, G. Faraji, and A. Siahsarani, Processing of AM60 magnesium alloy by hydrostatic cyclic expansion extrusion at elevated temperature as a new severe plastic deformation method, Int. J. Miner. Metall. Mater., 27(2020), No. 5, p. 669.

Z. Zhang, J.H. Zhang, J. Wang, Z.H. Li, J.S. Xie, S.J. Liu, K. Guan, and R.Z. Wu, Toward the development of Mg alloys with simultaneously improved strength and ductility by refining grain size via the deformation process, Int. J. Miner. Metall. Mater., 28(2021), No. 1, p. 30.

X.G. Qiao, T. Ying, M.Y. Zheng, E.D. Wei, K. Wu, X.S. Hu, W.M. Gan, H.G. Brokmeier, and I.S. Golovin, Microstructure evolution and mechanical properties of nano-SiCp/AZ91 composite processed by extrusion and equal channel angular pressing (ECAP), Mater. Charact., 121(2016), p. 222.

X.Y. Tao, J. Du, Y.C. Yang, Y.P. Li, Y. Xia, Y.P. Gan, H. Huang, W.K. Zhang, and X.D. Li, TiC nanorods derived from cotton fibers: Chloride-assisted VLS growth, structure, and mechanical properties, Cryst. Growth Des., 11(2011), No. 10, p. 4422.

M.J. Shen, W.F. Ying, X.J. Wang, M.F. Zhang, and K. Wu, Development of high performance magnesium matrix nanocomposites using nano-SiC particulates as reinforcement, J. Mater. Eng. Perform., 24(2015), No. 10, p. 3798.

M. Paramsothy, J. Chan, R. Kwok, and M. Gupta, Adding TiC nanoparticles to magnesium alloy ZK60A for strength/ductility enhancement, J. Nanomater., 2011(2011), art. No. 642980.

M. Rashad, F.S. Pan, W. Guo, H. Lin, M. Asif, and M. Irfan, Effect of alumina and silicon carbide hybrid reinforcements on tensile, compressive and microhardness behavior of Mg-3Al-1Zn alloy, Mater. Charact., 106(2015), p. 382.

S.S. Shuai, E.Y. Guo, J. Wang, A.B. Phillion, T. Jing, Z.M. Ren, and P.D. Lee, Synchrotron tomographic quantification of the influence of Zn concentration on dendritic growth in Mg−Zn alloys, Acta Mater., 156(2018), p. 287.

K.B. Nie, Z.H. Zhu, P. Munroe, K.K. Deng, and J.G. Han, The effect of Zn/Ca ratio on the microstructure, texture and mechanical properties of dilute Mg−Zn−Ca−Mn alloys that exhibit superior strength, J. Mater. Sci., 55(2020), No. 8, p. 3588.

K.B. Nie, Z.H. Zhu, P. Munroe, K.K. Deng, and J.G. Han, Microstructure, tensile properties and work hardening behavior of an extruded Mg−Zn−Ca−Mn magnesium alloy, Acta Metall. Sin. Engl. Lett., 33(2020), No. 7, p. 922.

B.C. Zhou, S.L. Shang, Y. Wang, and Z.K. Liu, Diffusion coefficients of alloying elements in dilute Mg alloys: A comprehensive first-principles study, Acta Mater., 103(2016), p. 573.

Y.N. Wang and J.C. Huang, Texture analysis in hexagonal materials, Mater. Chem. Phys., 81(2003), No. 1, p. 11.

A. Yang, K.B. Nie, K.K. Deng, and Y.N. Li, Improved tensile properties of low-temperature and low-speed extruded Mg−χAl−(4.8−χ)Ca−0.6Mn alloys, J. Mater. Res. Technol., 9(2020), No. 5, p. 11717.

Y.Z. Du, X.G. Qiao, M.Y. Zheng, K. Wu, and S.W. Xu, Development of high-strength, low-cost wrought Mg−2.5 mass% Zn alloy through micro-alloying with Ca and La, Mater. Des., 85(2015), p. 549.

D.K. Guan, W.M. Rainforth, L. Ma, B. Wynne, and J.H. Gao, Twin recrystallization mechanisms and exceptional contribution to texture evolution during annealing in a magnesium alloy, Acta Mater., 126(2017), p. 132.

M. Habibnejad-Korayem, R. Mahmudi, and W.J. Poole, Work hardening behavior of Mg-based nano-composites strengthened by Al2O3 nano-particles, Mater. Sci. Eng. A, 567(2013), p. 89.

G.K. Meenashisundaram and M. Gupta, Synthesis and characterization of high performance low volume fraction TiC reinforced Mg nanocomposites targeting biocompatible/structural applications, Mater. Sci. Eng. A, 627(2015), p. 306.

K.B. Nie, X.J. Wang, K. Wu, L. Xu, M.Y. Zheng, and X.S. Hu, Processing, microstructure and mechanical properties of magnesium matrix nanocomposites fabricated by semisolid stirring assisted ultrasonic vibration, J. Alloys Compd., 509(2011), No. 35, p. 8664.

W.J. Li, K.K. Deng, X. Zhang, C.J. Wang, J.W. Kang, K.B. Nie, and W. Liang, Microstructures, tensile properties and work hardening behavior of SiCp/Mg−Zn−Ca composites, J. Alloys Compd., 695(2017), p. 2215.

S.J. Shang, K.K. Deng, K.B. Nie, J.C. Li, S.S. Zhou, F.J. Xu, and J.F. Fan, Microstructure and mechanical properties of SiCp/Mg−Al−Zn composites containing Mg17Al12 phases processed by low-speed extrusion, Mater. Sci. Eng. A, 610(2014), p. 243.

X. Zhang, K.K. Deng, W.J. Li, H.X. Wang, K.B. Nie, F.J. Xu, and W. Liang, Microstructure and mechanical properties of Mg−Al−Ca alloy influenced by SiCp size, Mater. Sci. Eng. A, 647(2015), p. 15.

K.B. Nie, Y.C. Guo, K.K. Deng, and X.K. Kang, High strength TiCp/Mg−Zn−Ca magnesium matrix nanocomposites with improved formability at low temperature, J. Alloys Compd., 792(2019), p. 267.

X.J. Wang, K.B. Nie, X.S. Hu, Y.Q. Wang, X.J. Sa, and K. Wu, Effect of extrusion temperatures on microstructure and mechanical properties of SiCp/Mg−Zn−Ca composite, J. Alloys Compd., 532(2012), p. 78.

J.W. Kang, X.F. Sun, K.K. Deng, F.J. Xu, X. Zhang, and Y. Bai, High strength Mg−9Al serial alloy processed by slow extrusion, Mater. Sci. Eng. A, 697(2017), p. 211.

A. Sanaty-Zadeh, Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall-Petch effect, Mater. Sci. Eng. A, 531(2012), p. 112.

K.B. Nie, K.K. Deng, X.J. Wang, T. Wang, and K. Wu, Influence of SiC nanoparticles addition on the microstructural evolution and mechanical properties of AZ91 alloy during isothermal multidirectional forging, Mater. Charact., 124(2017), p. 14.

K.B. Nie, Z.H. Zhu, K.K. Deng, and J.G. Han, Effect of extrusion temperature on microstructure and mechanical properties of a low-alloying and ultra-high strength Mg−Zn−Ca−Mn matrix composite containing trace TiC nanoparticles, J. Magnes. Alloys, 8(2020), No. 3, p. 676.

Y.Z. Du, X.G. Qiao, M.Y. Zheng, K. Wu, and S.W. Xu, The microstructure, texture and mechanical properties of extruded Mg−5.3Zn−0.2Ca−0.5Ce (wt%) alloy, Mater. Sci. Eng. A, 620(2015), p. 164.

M. Habibnejad-Korayem, R. Mahmudi, and W.J. Poole, Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles, Mater. Sci. Eng. A, 519(2009), No. 1–2, p. 198.

K.B. Nie, J.G. Han, K.K. Deng, and Z.H. Zhu, Simultaneous improvements in tensile strength and elongation of a Mg−2Zn−0.8Sr−0.2Ca alloy by a combination of microalloying and low content of TiC nanoparticles, Mater. Lett., 260(2020), art. No. 126951.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51771129, 51401144, and 51771128); the Program for the Outstanding Innovative Teams of Higher Learning Institutions of Shanxi, China; the Natural Science Foundation of Shanxi Province, China (Nos. 2015021067 and 201601D011034); the Projects of International Cooperation in Shanxi, China (No. 201703D421039).

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Wang, Z., Nie, K., Deng, K. et al. Effect of extrusion on the microstructure and mechanical properties of a low-alloyed Mg−2Zn−0.8Sr−0.2Ca matrix composite reinforced by TiC nano-particles. Int J Miner Metall Mater 29, 1981–1990 (2022). https://doi.org/10.1007/s12613-021-2353-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-021-2353-8