Abstract

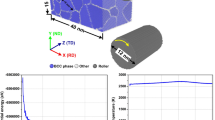

The microstructures of doped tungsten deformed by multi-pass hot continuous rolling were investigated, and the stress and strain fields were simulated by finite element (FE) method. After the continuous rolling, the grains of the tungsten rod were refined, and the microhardness was improved; however, a ring region of abnormal grain growth was present at a distance of about 3/5R (R is the radius of the rod) from the center of the cross section. FE modeling results showed that the equivalent residual strains were minimum around the region of abnormal grain growth; this was due to the release of strain energy by severe plastic deformation, leading a situation where the migration force of grain boundaries was higher than the pinning force of potassium bubbles. By decreasing the initial rolling temperature and rolling speeds, the inhomogeneity of the equivalent residual stain decreased, improving the microstructure uniformity of the doped tungsten.

Similar content being viewed by others

References

B. Huang, B. He, Y. Xiao, R. Ang, J.J. Yang, J.L. Liao, Y.Y. Yang, N. Liu, D. Pan, and J. Tang, Microstructure and bubble formation of Al-K-Si doped tungsten prepared by spark plasma sintering, Int. J. Refract. Met. Hard Mater., 54(2016), p. 335.

B. Katavic, Z. Odanovic, and M. Burzic, Investigation of the rotary swaging and heat treatment on the behavior of W- and —phases in PM 92.5W-5Ni-2.5Fe-0.26Co heavy alloy, Mater. Sci. Eng. A, 492(2008), No. 1–2, p. 337.

U.R. Kiran, A. Panchal, M. Sankaranarayana, and T.K. Nandy, Tensile and impact behavior of swaged tungsten heavy alloys processed by liquid phase sintering, Int. J. Refract. Met. Hard Mater., 37(2013), p. 1.

J. Habainy, S. Iyengar, Y. Lee, and Y. Dai, Fatigue behavior of rolled and forged tungsten at 25°C, 280°C and 480°C, J. Nucl. Mater., 465(2015), p. 438.

X.X. Zhang, Q.Z. Yan, S.T. Lang, Y.J. Wang, and C.C. Ge, Preparation of pure tungsten via various rolling methods and their influence on macro-texture and mechanical properties, Mater. Des., 126(2017), p. 1.

M. Nioi, S. Celotto, C. Pinna, E. Swart, and H. Ghadbeigi, Surface defect evolution in hot rolling of high-Si electrical steels, J. Mater. Process. Technol., 249(2017), p. 302.

J.H. Kim, J.H. Baek, S.H. Kim, C.B. Lee, K.S. Na, and S.J. Kim, Effect of hot rolling process on the mechanical and microstructural property of the 9Cr-1Mo steel, Ann. Nucl. Energy, 38(2011), No. 1, p. 2397.

Y. Cao, X.J. Shen, H.S. Di, and G.J. Huang, Texture and microstructure evolution of Incoloy 800H superalloy during hot rolling and solution treatment, J. Alloys Compd., 698(2017), p. 304.

G.K. Gupta, K.K. Patel, R. Purohit, and P. Bhagoria, Effect of rolling on Ni-Ti-Fe shape memory alloys prepared through novel powder metallurgy route, Mater. Today: Proc., 4(2017), No. 4, p. 5385.

M.V. Markushev, D.R. Nugmanov, O. Sitdikov, and A. Vinogradov, Structure, texture and strength of Mg-5.8Zn-0.65Zr alloy after hot-to-warm multi-step isothermal forging and isothermal rolling to large strains, Mater. Sci. Eng. A, 709(2018), p. 330.

V.V. Ravikumar and S. Kumaran, Improved strength and ductility of high alloy containing Al-12Zn-3Mg-2.5Cu alloy by combining non-isothermal step rolling and cold rolling, Int. J. Miner. Metall. Mater., 24(2017), No. 2, p. 179.

J. Wang, G.Q. Zhao, and M.J. Li, Establishment of processing map and analysis of microstructure on multi-crystalline tungsten plastic deformation process at elevated temperature, Mater. Des., 103(2016), p. 268.

Z. Yanushkevich, A. Belyakov, and R. Kaibyshev, Microstructural evolution of a 304-type austenitic stainless steel during rolling at temperatures of 773–1273 K, Acta Mater., 82(2015), p. 244.

W.Z. Chen, W.C. Zhang, Y.D. Qiao, Q. Miao, and E.D. Wang, Enhanced ductility in high-strength fine-grained magnesium and magnesium alloy sheets processed via multi-pass rolling with lowered temperature, J. Alloys Compd., 665(2016), p. 13.

K. Wang, X. Zan, M. Yu, W. Pantleon, L.M. Luo, X.Y. Zhu, P. Li, and Y.C. Wu, Effects of thickness reduction on recrystallization process of warm-rolled pure tungsten plates at 1350oC, Fusion Eng. Des., 125(2017), p. 521.

U. Hanoglu and B. Šarler, Multi-pass hot-rolling simulation using a meshless method, Comput. Struct., 194(2018), p. 1.

J.W. Ma, C.P. Yang, Z.H. Zheng, K.S. Zhang, and W.Y. Ma, Influence of process parameters on the microstructural evolution of a rear axle tube during cross wedge rolling, Int. J. Miner. Metall. Mater., 23(2016), No. 11, p. 1302.

M. Bambach and S. Seuren, On instabilities of force and grain size predictions in the simulation of multi-pass hot rolling processes, J. Mater. Process. Technol., 216(2015), p. 95.

S.Y. Yuan, L.W. Zhang, S.L. Liao, M. Qi, Y. Zhen, and S.Q. Guo, 3D FE analysis of thermal behavior of billet in rod and wire hot continuous rolling process, J. Iron Steel Res. Int., 14(2007), No. 1, p. 29.

F.L. Sui, Y. Zuo, X.H. Liu, and L.Q. Chen, Microstructure analysis on IN 718 alloy round rod by FEM in the hot continuous rolling process, Appl. Math. Modell., 37(2013), No. 20–21, p. 8776.

Z.Y. Jin, K. Yin, K. Yan, D.F. Wu, J. Liu, and Z.S. Cui, Finite element modelling on microstructure evolution during multi-pass hot compression for AZ31 alloys using incremental method, J. Mater. Sci. Technol., 33(2017), No. 11, p. 1255.

H.L. Ding, T.Y. Wang, L. Yang, and S. Kamado, FEM modeling of dynamical recrystallization during multi-pass hot rolling of AM50 alloy and experimental verification, Trans. Nonferrous Met. Soc. China, 23(2013), No. 9, p. 2678.

P.J. Hao, A.R. He, and W.Q. Sun, Formation mechanism and control methods of inhomogeneous deformation during hot rough rolling of aluminum alloy plate, Arch. Civ. Mech. Eng., 18(2018), No. 1, p. 245.

M. Yu, K. Wang, X. Zan, W. Pantleon, L.M. Luo, X.Y. Zhu, and Y.C. Wu, Hardness loss and microstructure evolution of 90% hot-rolled pure tungsten at 1200–1350oC, Fusion Eng. Des., 125(2017), p. 531.

T. Palacios, J. Reiser, J. Hoffmann, M. Rieth, A. Hoffmann, and J.Y. Pastor, Microstructural and mechanical characterization of annealed tungsten (W) and potassium-doped tungsten foils, Int. J. Refract. Met. Hard Mater., 48(2015), p. 145.

Acknowledgements

This work was financially supported by Shandong Provincial Key Research and Development Program, China (No. 2017GGX20140) and Shandong Provincial Natural Science Foundation, China (Nos. ZR2014JL031 and ZR2018MEE016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shao, Zj., Liu, Hp., He, Xc. et al. Microstructure and finite element analysis of hot continuous rolling of doped tungsten rod. Int J Miner Metall Mater 26, 369–376 (2019). https://doi.org/10.1007/s12613-019-1746-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1746-4