Abstract

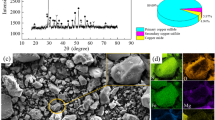

Lead, zinc, and iron were recovered from jarosite residues using direct reduction followed by magnetic separation. The influence of the coal dosage, reduction temperature, and reduction time on the volatilization rates of lead and zinc and the metallization rate of iron were investigated. The results show that the volatilization rates of lead and zinc were 96.97% and 99.89%, respectively, and the iron metallization rate was 91.97% under the optimal reduction roasting conditions of a coal dosage of 25.0wt% and reduction roasting at 1250°C for 60 min. The magnetic concentrate with an iron content of 90.59wt% and an iron recovery rate of 50.87% was obtained under the optimum conditions in which 96.56% of the reduction product particles were smaller than 37 μm and the magnetic field strength was 24 kA/m. Therefore, the results of this study demonstrate that recovering valuable metals such as lead, zinc, and iron from jarosite residues is feasible using the developed approach.

Similar content being viewed by others

References

D.C. Choque, F.N. Alonso, and J.C. Fuentes-Aceituno, Acid decomposition and thiourea leaching of silver from hazardous jarosite residues: Effect of some cations on the stability of the thiourea system, J. Hazard. Mater., 317(2016), No. 5, p. 440.

L. Montanaro, N. Bianchini, J.M. Rincon, and M. Romero, Sintering behaviour of pressed red mud wastes from zinc hydrometallurgy, Ceram. Int., 27(2001), No. 1, p. 29.

P. Asokan, M. Saxena, and S.R. Asolekar, Jarosite characteristics and its utilisation potentials, Sci. Total Environ., 359(2006), No. 1-3, p. 232.

P. Asokan, M. Saxena, and S.R. Asolekar, Recycling hazardous jarosite waste using coal combustion residues, Mater. Charact., 61(2010), No. 12, p. 1342.

S.H. Ju, Y.F. Zhang, Y. Zhang, P.Y. Xue, and Y.H. Wang, Clean hydrometallurgical route to recover zinc, silver, lead, copper, cadmium and iron from hazardous jarosite residues produced during zinc hydrometallurgy, J. Hazard. Mater., 192(2011), No. 2, p. 554.

M. Erdem and A. Özverdi, Environmental risk assessment and stabilization/solidification of zinc extraction residue: II. Stabilization/solidification, Hydrometallurgy, 105(2011), No. 3, p. 270.

A. Özverdi and M. Erdem, Environmental risk assessment and stabilization/solidification of zinc extraction residue: I. Environmental risk assessment, Hydrometallurgy, 100(2010), No. 3, p. 103.

E. Salinas, A. Roca, M. Cruells, F. Patiño, and D.A. Córdoba, Characterization and alkaline decomposition–cyanidation kinetics of industrial ammonium jarosite in NaOH media, Hydrometallurgy, 60(2001), No. 3, p. 237.

P. Asokan, M. Saxena, and S.R. Asolekar, Hazardous jarosite use in developing non-hazardous product for engineering application, J. Hazard. Mater., 137(2006), No. 3, p. 1589.

V.A. Mymrin, H.A. Ponte, and P.R. Impinnisi, Potential application of acid jarosite wastes as the main component of construction materials, Constr. Build. Mater., 19(2005), No. 2, p. 141.

Y.M. Chen, M.T. Tang, S.H. Yang, J. He, C.B. Tang, J.G. Yang, and J.Y. Lu, Novel technique of decomposition of ammonium jarosite bearing indium in NaOH medium, Chin. J. Nonferrous Met., 19(2009), No. 7, p. 1322.

H.P. Hu, Q.F. Deng, C. Li, Y. Xie, Z.Q. Dong, and W. Zhang, The recovery of Zn and Pb and the manufacture of lightweight bricks from zinc smelting slag and clay, J. Hazard. Mater., 271(2014), No. 5, p. 220.

H.S. Han, W. Sun, Y.H. Hu, B.L. Jia, and H.H. Tang, Anglesite and silver recovery from jarosite residues through roasting and sulfidization-flotation in zinc hydrometallurgy, J. Hazard. Mater., 278(2014), p. 49.

E.N. Malenga, A.M. Bafubiandi, and W. Nheta, Alkaline leaching of nickel bearing ammonium jarosite precipitate using KOH, NaOH and NH4OH in the presence of EDTA and Na2S, Hydrometallurgy, 155(2015), p. 69.

P.Y. Xue, S.H. Ju, Y.F. Zhang, and X.W. Wang, Recovery of valuable metals by leaching of roasted jarosite residue, Chin. J. Process Eng., 11(2011), No. 1, p. 56.

P. Mehra, R.C. Gupta, and B.S. Thomas, Properties of concrete containing jarosite as a partial substitute for fine aggregate, J. Cleaner Prod., 120(2016), p. 241.

D.B. Guo, M. Hu, C.X. Pu, B. Xiao, Z.Q. Hu, S.M. Liu, X. Wang, and X.L. Zhu, Kinetics and mechanisms of direct reduction of iron ore-biomass composite pellets with hydrogen gas, Int. J. Hydrogen Energy, 40(2015), No. 14, p. 4733.

Y.S. Sun, P. Gao, Y.X. Han, and D.Z. Ren, Reaction behavior of iron minerals and metallic iron particles growth in coal-based reduction of an oolitic iron ore, Ind. Eng. Chem. Res., 52(2013), No. 6, p. 2323.

Y.S. Sun, Y.X. Han, P. Gao, and J.W. Yu, Size distribution behavior of metallic iron particles in coal-based reduction products of an oolitic iron ore, Miner. Process. Extr. Metall. Rev., 36(2015), No. 4, p. 249.

W. Yu, T.C. Sun, Q. Cui, and J. Kou, Effect of coal type on the reduction and magnetic separation of a high-phosphorus oolitic hematite ore, ISIJ Int., 55(2015), No. 3, p. 536.

H.F. Yang, L.L. Jing, and B.G. Zhang, Recovery of iron from vanadium tailings with coal-based direct reduction followed by magnetic separation, J. Hazard. Mater. 185(2011), No. 2-3, p. 1405.

W. Liu, J. Yang, and B. Xiao, Application of Bayer red mud for iron recovery and building material production from alumosilicate residues, J. Hazard. Mater., 161(2009), No. 1, p. 474.

J.W. Park, J.C. Ahn, H. Song, K. Park, H. Shin, and J.S. Ahn, Reduction characteristics of oily hot rolling mill sludge by direct reduced iron method, Resour. Conserv. Recycl., 34(2002), No. 2, p. 129.

K. Maweja, T. Mukongo, and I. Mutombo, Cleaning of a copper matte smelting slag from a water-jacket furnace by direct reduction of heavy metals, J. Hazard. Mater., 164(2009), No. 2, p. 856.

G. Yu, N. Peng, L. Zhou, Y.J. Liang, X.Y. Zhou, B. Peng, L.Y. Chai, and Z.H. Yang, Selective reduction process of zinc ferrite and its application in treatment of zinc leaching residues, Trans. Nonferrous Met. Soc. China, 25(2015), No. 8, p. 2744.

H.F. Yang, B.P. Jiang, Y.Y. Wang, X.X. Yuan, and Y.Y. Zhang, Direct reduction effect of coal slime on zinc-leaching residue, Chin. J. Nonferrous Met., 25(2015), No. 1, p. 250.

Z.G. Liu, T.C. Sun, X.P. Wang, and E.X. Gao, Generation process of FeS and its inhibition mechanism on iron mineral reduction in selective direct reduction of laterite nickel ore, Int. J. Miner. Metall. Mater., 22(2015), No. 9, p. 901.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Yy., Yang, Hf., Jiang, B. et al. Comprehensive recovery of lead, zinc, and iron from hazardous jarosite residues using direct reduction followed by magnetic separation. Int J Miner Metall Mater 25, 123–130 (2018). https://doi.org/10.1007/s12613-018-1555-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-018-1555-1