Abstract

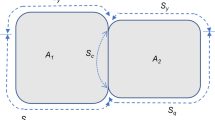

Expulsion is an undesired event during resistance spot welding because the weld quality deteriorates. It is the ejection of molten metal from the weld nugget which usually occurs due to applying a high current for a short welding time. Expulsion has a significant impact on the final yield strength of the weld, thus the detection and characterization of expulsion events is significant for the quality assurance of resistance spot welds. In this study, hardness mapping, using a scanning hardness machine, was used as a quality assurance technique for resistance spot welding. Hardness tests were conducted on a resistance spot welded sample to prepare a hardness map. The test results showed good correlation between the hardness map and metallographic cross sections. The technique also provided further fundamental understanding of the resistance spot welding process, especially regarding the occurrence of expulsion in the nugget.

Similar content being viewed by others

References

M. Naderi, A. Saeed-Akbari, and W. Bleck, Quantitative and qualitative investigation of the heterogeneous microstructures using surface hardness mapping and dilatation data, Mater. Lett., 62(2008), No. 6–7, p. 1132.

H. Ghazanfari, M. Naderi, M. Iranmanesh, M. Seydi, and A. Poshteban, A comparative study of the microstructure and mechanical properties of HTLA steel welds obtained by the tungsten arc welding and resistance spot welding, Mater. Sci. Eng. A, 534(2012), p. 90.

D.W. Moon, S.G. Lambrakos, R.J. Wong, and E.A. Metzbower, Macrostructure, hardness, and temperature in HSLA100 steel weld, Sci. Technol. Weld. Joining, 8(2003), No. 2, p. 95.

D.W. Moon, S.G. Lambrakos, R.J. Wong, and E.A. Metzbower, Temperature, macrostructure and hardness in high strength low alloy steel welds, Sci. Technol. Weld. Joining, 8(2003), No. 5, p. 334.

E.A. Metzbower, P.E. Denney, D.W. Moon, C.R. Feng, and S.G. Lambrakos, Thermal analysis and microhardness mapping in hybrid laser welds in a structural steel, Mater. Sci. Forum, 426–432(2003), p. 4147.

G. Fourlaris, S.J. Hambling, and T.B. Jones, Influence of steel strength and loading mode on fatigue properties of resistance spot welded H section specimen, Mater. Sci. Technol., 22(2006), No. 1, p. 39.

E. Crinon and J.T. Evans, The effect of surface roughness, oxide film thickness and interfacial sliding on the electrical contact resistance of aluminium, Mater. Sci. Eng. A, 242(1998), No. 1–2, p. 121.

M. Pouranvari, A. Abedi, P. Marashi, and M. Goodarzi, Effect of expulsion on peak load and energy absorption of low carbon steel resistance spot welds, Sci. Technol. Weld. Joining, 21(2008), No. 1, p. 39.

F. Nikoosohbat, S. Kheirandish, M. Goodarzi, M. Pouranvari, and S.P.H Marashi, Microstructure and failure behaviour of resistance spot welded DP980 dual phase steel, Mater. Sci. Technol., 26(2010), No. 6, p. 738.

S. Satonaka and K. Matsuyama, Review on inspection techniques for spot welds, Weld. World, 44(2000), No. 3, p. 4.

T.M. Mansour, Ultrasonic inspection of spot welds in thin-gage steel, Mater. Eval., 46(1988), No. 5, p. 650.

F. Eichhorn, K.J. Hamm, K. Powell, and G. Schmitz, The Role of Computers, Pergamon Press, Oxford, 1988, p. 113.

D.W. Zhao, Y.X. Wang, Z.G. Lin, and S.N. Sheng, An effective quality assessment method for small scale resistance spot welding based on process parameters, NDT & E Int., 55(2013), p.36.

H. Eisazadeh, M. Hamedi, and A. Halvaee, New parametric study of nugget size in resistance spot welding process using finite element method, Mater. Des., 31(2010), No. 1, p. 149.

H. Moshayedi and I. Sattari-Far, Numerical and experimental study of nugget size growth in resistance spot welding of austenitic stainless steels, J. Mater. Process. Technol., 212(2012), No. 2, p. 347.

S. Kou, Welding Metallurgy, John Wiley & Sons, New York, 2003.

H.Y. Zhang and J. Senkara, Resistance Welding: Fundamentals and Applications, CRC Press/Taylor & Francis Group, London, New York, 2006.

M. Pouranvari, S.M. Mousavizadeh, S.P.H. Marashi, M. Goodarzi, and M. Ghorbani, Influence of fusion zone size and failure mode on mechanical performance of dissimilar resistance spot welds of AISI 1008 low carbon steel and DP600 advanced high strength steel, Mater. Des., 32(2011), No. 3, p. 1390.

M. Goodarzi, S.P.H. Marashi, and M. Pouranvari, Dependence of overload performance on weld attributes for resistance spot welded galvanized low carbon steel, J. Mater. Process. Technol., 209(2009), No. 9, p. 4379.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghazanfari, H., Naderi, M. Expulsion characterization in resistance spot welding by means of a hardness mapping technique. Int J Miner Metall Mater 21, 894–897 (2014). https://doi.org/10.1007/s12613-014-0986-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0986-6