Abstract

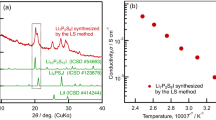

The nanocomposite of MoSi2-Si3N4 (molybdenum disilicide-silicon nitride) was synthesized by reaction milling of the Mo and Si powder mixture. Changing the processing parameters led to the formation of different products such as α- and β-MoSi2, Si3N4, Mo2N, and Mo5Si3 at various milling times. A thermodynamic appraisal showed that the milling of Mo32Si68 powder mixture was associated with highly exothermic mechanically induced self-sustaining reaction (MSR) between Mo and Si. The MSR took place around 5 h of milling led to the formation of α-MoSi2 and the reaction between Si and N2 to produce Si3N4 under a nitrogen pressure of 1 MPa. By increasing the nitrogen pressure to 5 MPa, more heat is released, resulting in the dissociation of Si3N4 and the transformation of α-MoSi2 to β-MoSi2. Heat treatment was also performed on the milled samples and led to the formation of Mo2N and the transformation of α-MoSi2 to β-MoSi2 at the milling times of 10 and 40 h, respectively.

Similar content being viewed by others

References

Z. Chen, J.C. Cuneo, J.J. Mecholsky, and S.F. Hu, Damage processes in Si3N4 bearing material under contact loading, Wear, 198(1996), No. 1–2, p. 197.

K. Yamada and N. Kamiya, High temperature mechanical properties of Si3N4-MoSi2 and Si3N4-SiC composites with network structures of second phases, Mater. Sci. Eng. A, 261(1999), No. 1, p. 270.

J.J. Petrovic, M.I. Pena, and H.H. Kung, Fabrication and microstructures of MoSi2 reinforced-Si3N4 matrix composites, J. Am. Ceram. Soc., 80(1997), No. 5, p. 1111.

A.H. Bartlett and R.G. Castro, Elevated temperature mechanical properties of MoSi2/Si3N4, MoSi2/SiC composites produced by self-propagating high temperature synthesis, J. Mater. Sci., 33(1998), No. 6, p. 1653.

N.J. Welham, P.E. Willis, and T. Kerr, Mechanochemical formation of metal-ceramic composites, J. Am. Ceram. Soc., 83(2000), No. 1, p. 33.

S. Singh, M.M. Godkhindi, R.V. Krishnarao, and B.S. Murty, Synthesis of Si3N4-MoSi2 in situ composite from mechanically activated (Mo+Si3N4) powders, J. Alloys Compd., 381(2004), No. 1–2, p. 254.

N.R. Park, I.Y. Yoon, J.M. Doh, and I.J. Shon, Properties and rapid consolidation of nanocrystalline 8MoSi2-Si3N4 by high frequency induction heated sintering, Met. Mater. Int., 17(2011), No. 2, p. 233.

C. Suryanarayana, E. Ivanov, and V.V. Boldyrev, The science and technology of mechanical alloying, Mater. Sci. Eng. A, 304–306(2001), p. 151.

C. Suryanarayana, Recent developments in mechanical alloying, Rev. Adv. Mater. Sci., 18(2008), p. 203.

T.P. Yadav, R.M. Yadav, and D.P. Singh, Mechanical milling: a top down approach for the synthesis of nanomaterials and nanocomposites, Nanosci. Nanotechnol., 2(2012), No. 3, p. 22.

H.M. Rietveld, A profile refinement method for nuclear and magnetic structures, J. Appl. Crystallogr., 2(1969), p. 65.

B.K. Yen, T. Aizawa, and J. Kihara, Synthesis and formation mechanisms of molybdenum silicides by mechanical alloying, Mater. Sci. Eng. A, 220(1996), No. 1–2, p. 8.

L. Takacs, Self-sustaining reactions induced by ball milling, Prog. Mater. Sci., 47(2002), No. 4, p. 355.

F.M. Heurle, C.S. Petersson, and M.Y. Tsai, Observations on the hexagonal form of MoSi2 and WSi2 films produced by ion implantation and on related snowplow effects, J. Appl. Phys., 51(1980), No. 11, p. 5976.

P.Z. Feng, A. Farid, X.H. Wang, I.S. Humail, and X.H. Qu, Mechanically activated reactive synthesis of refractory molybdenum and tungsten silicides, Int. J. Refract. Met. Hard Mater., 26(2008), No. 3, p. 173.

Y. Muramatsu, S. Wanikawa, M. Otaguchi, H. Okada, and A. Fujio, Gas contamination due to milling atmospheres of mechanical alloying and its effect on impact strength, J. Jpn Inst. Met., 68(2004), No. 1, p. 21.

C. Suryanarayana, Mechanical alloying and milling, Prog. Mater. Sci., 46(2001), No.1–2, p. 1.

L.L. Shaw, Z.G. Yang, and R.M. Ren, Synthesis of nanostructured Si3N4/SiC composite powders through high energy reaction milling, Mater. Sci. Eng. A, 244(1998), No. 1, p. 113.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdellahi, M., Amereh, A., Bahmanpou, H. et al. Rapid synthesis of MoSi2-Si3N4 nanocomposite via reaction milling of Si and Mo powder mixture. Int J Miner Metall Mater 20, 1107–1114 (2013). https://doi.org/10.1007/s12613-013-0841-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-013-0841-1