Abstract

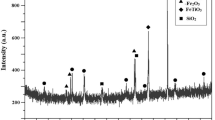

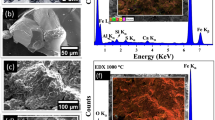

Solid wastes generated by the metallurgical industry contribute significantly towards the enhancement of environmental pollution. The handling, utilization, and safe disposal of these solid wastes are major concerns for the world. Dolochar is such a solid waste generated by the sponge iron industry. Investigations were carried out on the physical, mineralogical, and chemical characteristics for the efficient utilization of dolochar. The detailed studies on physico-chemical properties and petrography were carried out by optical microscopy, X-ray diffraction (XRD), and scanning electron microscopy (SEM). Characterization studies revealed that the dolochar consists of quartz (free as well as locked), free lime, Fe particles, and Ca or Mg and/or Ca+Mg+Fe oxide phases. The washability data of −300 μm dolochar samples indicated that clean coal with 41wt% ash at 18% yield can be produced from dolochar with 78wt% ash. The studies further suggested that the liberation of the dolochar is hard to achieve for clear separation. The dolochar is observed to have high ash fusion temperature and the unburned carbon can be best utilized for power generation.

Similar content being viewed by others

References

R. Barranco-Melendez, The Characterisation and Combustion of South American Coals [Dissertation], The University of Nottingham, Nottingham, 2001.

R.B. Jones, C. Morley, and C.B. McCourt, Maceral effects on the morphology and combustion of coal char, [in] Proceedings International Conference on Coal Science, Sydney, 1985, p.669.

J.G. Bailey, A. Tate, C.F.K. Diessel, and T.F. Wall, A char morphology system with application to coal combustion, Fuel, 69(1990), p.225.

E. Lester, M. Cloke, and M. Allen, Char characterization using image analysis techniques, Energy Fuels, 10(1996), p.696.

D. Alvarez, A.G. Borrego, and R. Menéndez, Unbiased methods for the morphological description of char structures, Fuel, 76(1997), p.1241.

P. Lightman and P.M. Street, Microscopical examination of heat treated pulverized coal particles, Fuel, 47(1968), p.7.

P.J. Street, R.P. Weight, and P. Lightman, Further investigation of structural changes occurring in pulverized coal particles during rapid heating, Fuel, 48(1969), p.343.

M. Shibaoka, Microscopic investigation of unburnt char fly ash, Fuel, 64(1985), p.263.

The Combustion Working Group, Atlas of Char Occurrences, The International Committee for Coal and Organic Petrology (ICCP), CD-ROM, 2000.

O. Levenspiel, Chemical Reaction Engineering, 3rd Ed., Wiley, New York, 1999.

R.H. Hurt and R.E. Mitchell, Unified high-temperature char combustion kinetics for a suite of coals of various rank, Symp. Int. Combust., 24(1992), p.1243.

R.H. Hurt, J.K. Sun, and M. Lunden, A kinetic model of carbon burnout in pulverized coal combustion, Combust. Flame, 113(1998), p.181.

M. Cloke, T. Wu, R. Barranco, and E. Leste, Char characterisation and its application in a coal burnout model, Fuel, 82(2003), p.1989.

P.A. Botha, Iron ore sinter produced from a mix containing waste materials, J. South Afr. Inst. Min. Metall., 93(1993), No.1, p.13.

A. Chatterjee, A critical appraisal of sponge iron production technologies, [in]_Proceedings of National Seminar on Potential of Sponge Iron in Indian Steel Industry, Ranchi, 2005.

A.K. Swar, Regulatory mechanism adopted to control pollution in DRI steel plants of Orissa for protection of environment, [In] Proceedings of International Convention on Clean Green and Sustainable Technologies in Iron and Steel Making, Bhubaneswar, 2009, p.25.

B. Das, S. Prakash, S.K. Biswal, and P.S.R. Reddy, Utilization of Solid Wastes Generated at Sponge Iron Industries of Odisha by Physical Beneficiation Techniques, Internal Report, Report No. T/MPT/462/June/2004, Institute of Minerals and Materials Technology, Bhubaneswar, 2004.

L. Panda, B. Das. D.S. Rao, and B.K. Mishra, Application of dolochar in the removal of cadmium and hexavalent chromium ions from aqueous solutions, J. Hazard. Mater., 192(2011), p.822.

W.J. Song, L.H. Tang, X.D. Zhu, Y.Q. Wu, Z.B. Zhu, and S. Koyama, Effect of coal ash composition on ash fusion temperatures, Energy Fuels, 24(2010), p.182.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the Odisha State Pollution Control Board, Bhubaneswar, India.

Rights and permissions

About this article

Cite this article

Dwari, R.K., Rao, D.S., Swar, A.K. et al. Characterization of dolochar wastes generated by the sponge iron industry. Int J Miner Metall Mater 19, 992–1003 (2012). https://doi.org/10.1007/s12613-012-0660-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-012-0660-9