Abstract

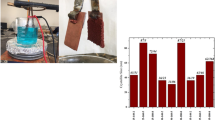

The influences of cupric ion concentration (5–35 g/L), current density (500–2000 A/m2), circulation rate of the electrolyte solution (15–120 mL/min), and temperature (25–60°C) on the physical and chemical properties of copper powders obtained in electrolysis cells were investigated. Two industrial processes, electrorefining (ER) cells with a synthetic electrolyte and electrowinning (EW) cells with an original solution of copper mineral leaching, were utilized to produce copper powders. Finally, the statistical full factorial method of design of experiments (DOE) was employed to investigate the interaction or the main effects of processes. The results show that increasing the copper concentration and temperature can increase the grain size, apparent density, and electrical energy consumption. On the other hand, increasing the current density and circulation rate of the electrolyte can decrease them. This production process is optimized via DOE to control the interactive and main effects to produce copper powders with favorable properties.

Similar content being viewed by others

References

P.W. Taubenblat, Importance of copper in powder metallurgy, Int. J. Powder Metall., 39(2003), No.4, p.25.

M. Mitkov and D. Božić, Hydride-dehydride conversion of solid Ti6Al4V to powder form, Mater. Charact., 37(1996), No.2–3, p.53.

M.R. German, Powder Metallurgy Science, Metal Powder Industries Federation, Princeton NJ, 1994.

S.P. Wu, H.L. Qin, and P. Li, Preparation of fine copper powders and their application in BME-MLCC, J. Univ. Sci. Technol. Beijing, 13(2006), No.3, p.250.

I.S. Humail, X.H. Qu, C.C Jia, et al., Morphology and microstructure characterization of 95W-3.5Ni-1.5Fe powder prepared by mechanical alloying, J. Univ. Sci. Technol. Beijing, 13(2006), No.5, p.442.

K.I. Popov, S.B. Krstić, M.č. Obradović, et al., The effect of the particle shape and structure on the flowability of electrolytic copper powder. III. A model of the surface of a representative particle of flowing copper powder electrodeposited by reversing current, J. Serb. Chem. Soc., 69(2004), No.1, p.43.

Literature review, Met. Powder Rep., 62(2007), No.4, p.33.

M. Raja, J. Subha, F.B. Ali, and S.H. Ryu, Synthesis of copper nanoparticles by Electroreduction Process, Mater. Manuf. Processes, 23(2008), No.8, p.782

R. Winand, Electrocrystallization: theory and applications, Hydrometallurgy, 29(1992), No.1–3, p.569.

O. Gladysz, P. Los, and E. Krzyzak, Influence of concentrations of copper, levelling agents and temperature on the diffusion coefficient of cupric ions in industrial electro-refining electrolytes, J. Appl. Electrochem., 37(2007), No.10, p.1093.

I.B. Murashova, Electrochemical methods of metal powder production, Handbook of Non-Ferrous Metal Powders, Elsevier, Oxford, 2009. p.181.

N.D. Nikolić, Lj.J. Pavlović, M.G. Pavlović, and K.I. Popov, Morphologies of electrochemically formed copper powder particles and their dependence on the quantity of evolved hydrogen, Powder Technol., 185(2008), No.3, p.195.

S.S. Naboychenko, I.B. Murashova, and O.D. Neikov, Production of copper and copper alloy powders, Handbook of Non-Ferrous Metal Powders, Elsevier, Oxford, 2009. p.331.

G. Orhan and G. Hapçi, Effect of electrolysis parameters on the morphologies of copper powder obtained in a rotating cylinder electrode cell, Powder Technol., 201(2010), No.1, p.57.

Literature review, Met. Powder Rep., 62(2007), No.2, p.36.

S. Xue, L.G. Meng, and Q.X. Guo, Copper powder-mediated homocoupling reactions of iodoacetylenes to synthesize symmetrical 1,3-butadiynes, Synth. Commun., 38(2008), No.13, p.2243.

A. Agrawal, S. Kumari, D. Bagchi, et al., Recovery of copper powder from copper bleed electrolyte of an Indian copper smelter by electrolysis, Miner. Eng., 20(2007), No.1, p.95.

V.V. Malyshev, A.I. Gab, and M. Gaune-Escard, Molybdenum electrometallurgical processes in ionic melts, Mater. Manuf. Processes, 23(2008), No.8, p.748.

Z.G. Li, C.C Jia, Y.T. He, and L.L. Chen, Kinetic characteristics of liquid phase sintering of mechanically activated W-15wt% Cu powder, J. Univ. Sci. Technol. Beijing, 13(2006), No.4, p.338.

A.M. Alfantazi and D. Valic, A study of copper electrowinning parameters using a statistically designed methodology, J. Appl. Electrochem., 33(2003), No.2, p.217.

E. Akbarzadeh and M. Ehteshamzadeh, Consideration of physical and chemical parameters on electrolytic copper powder properties with design experiment methods, [in] 12th Annual Conference of the Iranian Metallurgical Engineering Society, Islamic Azad University, Karaj, 2008.

M.G. Pavlović, Lj.J. Pavlović, E.R. Ivanović, et al., The effect of particle structure on apparent density of electrolytic copper powder, J. Serb. Chem. Soc., 66(2001), No.11–12, p.923.

M.G. Pavlović, Lj.J. Pavlović, I.D. Doroslovački, and N.D. Nikolić, The effect of benzoic acid on the corrosion and stabilisation of electrodeposited copper powder, Hydrometallurgy, 73(2004), No.1–2, p.155.

T.N. Andersen, D.L. Adamson, and K.J. Richards, The corrosion of lead anodes in copper electrowinning, Metall. Trans. B, 5(1974), No.6, p.1345.

A. Owais, Effect of electrolyte characteristics on electrowinning of copper powder, J. Appl. Electrochem., 39(2009), No.9, p.1587.

M.G. Pavlović, The effect of some parameters of electrolysis on apparent density of electrolytic copper powder in galvanostatic deposition, Mater. Sci. Forum, 352(2000), p.65.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akbarzadeh, E., Shakib, S.E. Comparison of effective parameters for copper powder production via electrorefining and electrowinning cells and improvement using DOE methods. Int J Miner Metall Mater 18, 731–740 (2011). https://doi.org/10.1007/s12613-011-0504-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-011-0504-z