Abstract

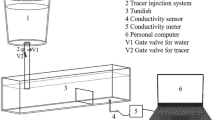

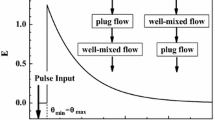

In a multistrand, the outlet near the inlet produces short circuiting flow. This leads to the formation of dead zones inside the tundish, and consequently, the mean residence time decreases. In the present study, numerical investigation of mixing inside a delta shaped tundish with sloping boundaries was carried out by solving the Navier-Stokes equation and employing the standard turbulence model. To decrease the dead zone volume inside the tundish, the effect of closing the outlet near the inlet for a small amount of time and further opening it on the mixing behavior of the tundish was studied. The outlets near the inlet were closed for varying amount of time, and the transient analysis of fluid flow and the tracer dispersion study were carried out to find the mixing parameters of the tundish, namely, mean residence time and the ratio of mixed to dead volume of the tundish. An optimum closure time of the near outlet has been found, which yields best mixing inside the tundish. The numerical code was validated against the experimental observation by performing the tracer dispersion study inside a multistrand tundish and the reasonably good match between the experimental and numerical results in terms of residence time distribution (RTD) curves. The results obtained from the present study confirm the strong role of choosing the right time for opening and closing the outlets to get improved characteristics for the fluid flow and mixing behavior of the tundish. The educational version of computational fluid dynamics (CFD) software PHOENICS was used to solve the governing equations and interpret the results in different forms.

Similar content being viewed by others

Abbreviations

- C :

-

Concentration of the tracer, kg·m−3

- C av,i :

-

Average concentration of the tracer at outlet i, kg·m−3

- D :

-

Derivative, s−1

- k :

-

Turbulent kinetic energy, m2·s−2

- MRT:

-

Mean residence time, s

- P :

-

Pressure, kg·m−1·s−2

- RTD:

-

Residence time distribution

- t :

-

Time, s

- t r :

-

Actual mean residence time of the fluid in the vessel, s

- U :

-

Mean velocity, m·s−1

- \(\overline {u_i u_j }\) :

-

Average turbulent stress, kg·m−1·s−2

- V :

-

Volume of the tundish, m3

- ɛ :

-

Dissipation rate of turbulent kinetic energy, m2·s−3

- μ :

-

Coefficient of viscosity, kg·m−3

- ν :

-

Kinematic viscosity, m2·s−1

- ρ :

-

Density of fluid, kg·m−1·s−1

- τ :

-

Theoretical mean residence time, s

- d:

-

Dead volume

- i, j, k :

-

Three cartesian coordinate directions x, y, and z

- m:

-

Mixed volume

- p:

-

Plug volume

References

S. Singh and S.C. Koria, Physical modelling of steel flow in continuous casting tundish, Ironmaking Steelmaking, 20(1993), No.3, p.221.

S.C. Koria and S. Singh, Physical modeling of the effects of the flow modifier on the dynamics of molten steel flowing in a tundish, ISIJ Int., 34(1994), p.784.

L.F. Zhang and B.G. Thomas, Fluid flow and inclusion motion in the continuous casting strand, [in] Proceedings of the XXIV Steelmaking National Symposium, Morelia, Mexico, 2003, p184.

P.K. Jha, S.K. Dash, and S. Kumar, Fluid flow and mixing in a six strand billet caster tundish: a parametric study, ISIJ Int., 41(2001), p.1437.

D. Mazumdar, G. Yamanoglu, R. Sankarnarayanan, and R.I.L. Guthrie, Similarity considerations in the physical modelling of steel making tundish systems, Steel Res., 66(1995), No.1, p.14.

D. Mazumdar, G. Yamanoglu, and R.I.L. Guthrie, Hydrodynamic performance of steelmaking tundish systems: a comparative study of three different tundish designs, Steel Res., 68(1997), No.7, p.293.

A. Tripathi and S.K. Ajmani, Numerical investigation of fluid flow phenomenon in a curved shape tundish of billet caster, ISIJ Int., 45(2005), p.1616.

B. Moumtez, A. Bellaouar, and K. Talbi, Numerical investigation of the fluid flow in continuous casting tundish using analysis of RTD curves, J. Iron Steel Res. Int., 16(2009), No.2, p.22.

P.K. Jha and S.K. Dash, Effect of outlet positions and various turbulence models on mixing in a single and multi strand tundish, Int. J. Numer. Methods Heat Fluid Flow, 12(2002), p.560.

B.E. Launder and D.B. Splading, Phoenics Reference Guide, CHAM Ltd., London, 1999.

D. Mazumdar and R. Guthrie, The physical and mathematical modelling of continuous casting tundish systems, ISIJ Int., 39(1999), No.6, p.524.

S. Yogeshwar and E. Toshihiko, Tundish Technology for Clean Steel Production, World Scientific Press, New York, 2007, p.328.

P.K. Jha, P.S. Rao, and A. Dewan, Effect of height and position of dams on inclusion removal in a six strand tundish, ISIJ Int., 48(2008), No.2, p.154.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mishra, S.K., Jha, P.K., Sharma, S.C. et al. Numerical investigation of the effect of transitory strand opening on mixing in a multistrand tundish. Int J Miner Metall Mater 18, 535–542 (2011). https://doi.org/10.1007/s12613-011-0474-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-011-0474-1