Abstract

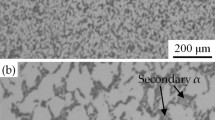

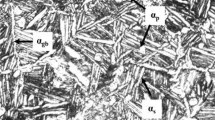

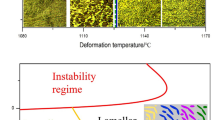

The effect of processing parameters on the flow response and microstructural evolution of the α+β titanium alloy Ti-6.5Al-3.5Mo-1.5Zr-0.3Si has been studied by conducting isothermal hot compressive tests at a strain rate of 0.01–10 s−1 at 860–1100°C. The true stress-true strain curves of the sample hot-compressed in the α+β phase region exhibit a peak stress followed by continuous flow softening, whereas in the β region, the flow stress attains a steady-state regime. At a strain rate of 10 s−1, the alloy exhibits plastic flow instabilities. According to the kinetic rate equation, the apparent activation energies are estimated to be about 674–705 kJ/mol in the α+β region and 308–335 kJ/mol in the β region, respectively. When deformed in the α+β region, the globularization process of the α colony structure occurs, and α dynamic recrystallized microstructures are observed to show bimodal. Dynamic recrystallization can take place in the β region irrespective of starting deformed structures.

Similar content being viewed by others

References

R. Filip, K. Kubiak, W. Ziaja, and J. Sieniawski, The effect of microstructure on the mechanical properties of two-phase titanium alloys, J. Mater. Process. Technol., 133(2003), p.84.

M. Jackson and K. Dring, Materials perspective: A review of advances in processing and metallurgy of titanium alloys, Mater. Sci. Technol., 22(2006), p.881.

Y.B. Chun and S.K. Hwang, Static recrystallization of warm-rolled pure Ti influenced by microstructural inhomogeneity, Acta Mater., 56(2008), p.369.

R. Ding, Z.X. Guo, and A. Wilson, Microstructural evolution of a Ti-6Al-4V alloy during thermomechanical processing, Mater. Sci. Eng. A, 327(2002), p.233.

S.L. Semiatin and T.R. Bieler, The effect of alpha platelet thickness on plastic flow during hot working of TI-6Al-4V with a transformed microstructure, Acta Mater., 49(2001), p.3565.

R.C. Picu and A. Majorell, Mechanical behavior of Ti-6Al-4V at high and moderate temperatures—Part II. Constitutive modeling, Mater. Sci. Eng. A, 326(2002), p.306.

P. Wanjara, M. Jahazi, H. Monajati, and S. Yue, Influence of thermomechanical processing on microstructural evolution in near-α alloy IMI834, Mater. Sci. Eng. A, 416(2006), p.300.

J.T. Liu, G.Q. Liu, and B.F. Hu, Hot deformation behavior of FGH96 superalloys, J. Univ. Sci. Technol. Beijing, 13(2006), p.319.

P.L. Martin, Effects of hot working on the microstructure of Ti-base alloys, Mater. Sci. Eng. A, 243(1998), p.25.

I. Weiss, F.H. Froes, D. Eylon, and G.E. Welsch, Modification of alpha morphology in Ti-6Al-4V by thermomechanical processing, Metall. Trans. A, 17(1986), p.1935.

S.L. Semiatin, V. Seetharaman, and I. Weiss, Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure, Mater. Sci. Eng. A, 263(1999), p.257.

M.F. Savage, J. Tatalovich, M. Zupan, et al., Deformation mechanisms and microtensile behavior of single colony Ti-6242Si, Mater. Sci. Eng. A, 319–321(2001), p.398.

M.Q. Li, X.M. Liu, and A.M. Xiong, Prediction of the mechanical properties of forged TC11 titanium alloy by ANN, J. Mater. Process. Technol., 121(2002), p.1.

A.B. Li, L.J. Huang, Q.Y. Meng, et al., Hot working of Ti-6Al-3Mo-2Zr-0.3Si alloy with lamellar α+β starting structure using processing map, Mater. Des., 30(2009), p.1625.

B. Poorganji, M. Yamaguchi, Y. Itsumi, et al., Microstructure evolution during deformation of a near-α titanium alloy with different initial structures in the two-phase region, Scripta Mater., 61(2009), p.419.

N.S. Reddy, Y.H. Lee, C.H. Park, and C.S. Lee, Prediction of flow stress in Ti-6Al-4V alloy with an equiaxed α+β microstructure by artificial neural networks, Mater. Sci. Eng. A, 492(2008), p.276.

S. Bruschi, S. Poggio, F. Quadrini, and M.E. Tata, Workability of Ti-6Al-4V alloy at high temperatures and strain rates, Mater. Lett., 58(2004), p.3622.

I. Weiss and S.L. Semiatin, Thermomechanical processing of alpha titanium alloys—An overview, Mater. Sci. Eng. A, 263(1999), p.243.

T. Sheppard and J. Norley, Deformation characteristics of Ti-6Al-4V, Mater. Sci. Technol., 4(1988), p.903.

L. Briottet, J.J. Jonas, and F. Montheillet, A mechanical interpretation of the activation energy of high temperature deformation in two phase materials, Acta Mater., 44(1996), p.1665.

S.L. Semiatin, F. Montheillet, G. Shen, et al., Self-consistent modeling of the flow behavior of wrought alpha/beta titanium alloys under isothermal and nonisothermal hot-working conditions, Metall. Mater. Trans. A, 33(2002), p.2719.

R. Mythili, S. Saroja, and M. Vijayalakshmi, Study of mechanical behavior and deformation mechanism in an α-β Ti-4.4Ta-1.9Nb alloy, Mater. Sci. Eng. A, 454–455(2007), p.43.

S.I. Oh, S.L. Semiatin, and J.J. Jonas, An analysis of the isothermal hot compression test, Metall. Trans. A, 23(1992), p.963.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the National Natural Science Foundation of China (No.50901063), the Program of Science and Technology of Shandong Province, China (No.2007DS04014, 2007BS05006), and the Open Research Fund from the State Key Laboratory of Rolling and Automation of Northeastern University, China.

Rights and permissions

About this article

Cite this article

Liu, Gf., Zhang, Sz., Chen, Lq. et al. Deformation behavior and microstructural evolution during hot compression of an α+β Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy. Int J Miner Metall Mater 18, 344–351 (2011). https://doi.org/10.1007/s12613-011-0445-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-011-0445-6