Abstract

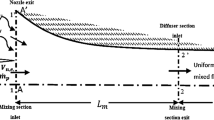

Based on the two-phase fluid (Eulerian-Eulerian) model, a mathematical model about the gas-liquid flow and mixing behavior was developed to investigate the effect of the offset of dual plugs, the included angle of dual plugs with a center point, and gas flow rate on the mixing time in a ladle with dual plugs. Numerical results indicate that two types of recirculation zones exist in the ladle. One is the middle recirculation between gas and liquid plumes, and the other is the sidewall recirculation between plumes and the ladle sidewall. The correction shows that the mixing time is in proportion to −0.2676 power of gas flow rate. There is a unique optimum offset of dual plugs with a particular included angle, in turn, a unique optimum included angle of dual plugs exits with a particular offset.

Similar content being viewed by others

References

M. Warzecha, J. Jowsa, P. Warzecha, and H. Pfeifer. Numerical and experimental investigations of steel mixing time in a 130-t ladle, Steel Res. Int., 79(2008), No.11, p.852.

D. Mazumdar and J. W. Evans, Macroscopic models for gas stirred ladles, ISIJ Int., 44(2004), No.3, p.447.

S. Joo and R.I.L. Guthrie, Modeling flows and mixing in steelmaking ladles designed for single- and dual-plug bubbling operations, Metall. Mater. Trans. B, 23(1992), No.6, p.765.

M.Y. Zhu, T. Inomoto, I. Sawada, and T.C. Hsiao, Fluid fow and mixing phenomena in the ladle stirred by argon through multi-tuyere, ISIJ Int., 35(1995), No.5, p.472.

J. Mandal, S. Patil, M. Madan, and D. Mazumdar, Mixing time and correlation for ladles stirred with dual porous plugs, Metall. Mater. Trans. B, 36(2005), No.4, p.479.

M. Madan, D. Satish, and D. Mazumdar. Modeling of mixing in ladles fitted with dual plugs, ISIJ Int., 45(2005), No.5, p.677.

H.Y. Tang, J.S. Li, C. H. Xie, S.F. Yang, K.M. Sun, and D.S. Wen, Rational argon stirring for a 150-t ladle furnace, Int. J. Miner. Metall. Mater., 16(2009), No.4, p.383.

L. Zhang and B.G. Thomas, State of the art in evaluation and control of steel cleanliness, ISIJ Int., 43(2003), No.3, p.271.

J.H. Wei and H T. Hu, Mathematical modelling of molten steel flow process in a whole RH degasser during the vacuum circulation refining process: Mathematical model of the flow, Steel Res. Int., 77(2006), No.1, p.32.

H. Turkoglu and B. Farouk, Mixing time and liquid circulation rate in steelmaking ladles with vertical gas injection, ISIJ Int., 31(1991), No.12, p.1371.

P. Chen, J. Sanyal, and M.P. Dudukovic, CFD modeling of bubble columns flows: implementation of population balance, Chem. Eng. Sci., 59(2004), No.22, p.5201.

M. Sano and K. Mori, Size of bubbles in energetic gas injection into liquid metal, Trans. Iron Steel Inst. Jpn., 20(1980), No.10, p.675.

S.K. Ajmani, Dash, S. Chandra, and C. Bhanu. Mixing evaluation in the RH process using mathematical modelling, ISIJ Int., 44(2004), No.1, p.82.

F. Ahrenhold and W. Pluschkell, Mixing phenomena inside the ladle during RH decarburization of steel melts, Steel Res. Int., 70(1999), No.8, p.314.

S.V. Patankar and D.B. Spalding, A calculation procedure for heat, mass and momentum transfer in three-dimensional parabolic flows, Int. J. Heat Mass Transfer, 15(1972), No.10, p.1787.

D. Guo and G.A. Irons, Modeling of gas-liquid reactions in ladle metallurgy: Part I. Physical Modeling, Metall. Mater. Trans. B, 31(2000), No.6, p.1447.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the National High-tech Research and Development Program of China (No.2009AA03Z530), the National Natural Science Foundation of China and Shanghai Baosteel (No.50834010), and the Key Project of the Ministry of Education of China (No.108036).

Rights and permissions

About this article

Cite this article

Geng, Dq., Lei, H. & He, Jc. Optimization of mixing time in a ladle with dual plugs. Int J Miner Metall Mater 17, 709–714 (2010). https://doi.org/10.1007/s12613-010-0378-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-010-0378-5