Abstract

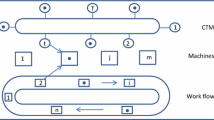

The problem of decreasing production costs through an appropriate management of available resources is fundamental in the field of industrial production. The performance of a flexible manufacturing system (FMS), not properly supported by an efficient resource management strategy, may be drastically limited, & the advantages derived from its flexibility in terms of production costs may suffer a sharp reduction. Furthermore, an FMS is composed of a large number of components, thus making the identification of a correct strategy for the management more difficult. In this paper a heuristic based genetic algorithm is proposed for generating optimized production plans in flexible manufacturing systems. The ability of the system to generate alternative plans following part-flow changes & unforeseen situations is particularly stressed (dynamic scheduling). The Key-point objective is the reduction of machine idle time obtained by an optimized evolutionary strategy needed to reach the optimal schedule in complex manufacturing systems.

Similar content being viewed by others

References

Guo, Z.X., Wong, W.K., Leung, S.Y.S., Fan, J.T., Chan, S.F.: Mathematical model and genetic optimization for the job-shop scheduling problem in a mixed and multi-product assembly environment: a case study. Comput. Ind. Eng 55, 202–219 (2006)

Hejazi, S., Saghafian, S.: Flow shop-scheduling problems with makespan criterion: a review. Int. J. Res. 43, 2895–2929 (2005)

Lauff, V., Werner, F.: Scheduling with common due dates, earliness and tardiness penalties for multi-machine problems: a survey.. Math. Comput. Model 40, 637–655 (2004)

Hasija, S., Rajendran, C.: Scheduling in flow shops to minimize total tardiness of jobs. Int. J. Prod. Res 42, 2289–2301 (2004)

Chan, F., Chan, H.: A comprehensive survey and future trend of simulation study on FMS scheduling. J. Intell. Manuf. 15, 87–102 (2004)

Ying, K., Liao, C.: An ant colony system for scheduling problems. Prod. Plan Control 14, 681–685 (2003)

Yen, B., Wan, G.: Single-machine bicriteria scheduling: a survey. Ind. J. Eng. Theory 10, 222–231 (2003)

Gordon, V., Proth, J., Chu, C.: A survey of the state-of-the art of common due to date arrangement and scheduling research. Eur. J. Oper. Res 139, 1–25 (2002)

Subramaniam, V., Lee, G., Ramesh, T., Hong, G., Wong, Y.: Machine selection rules in a dynamic job shop.. Int. J. Adv. Manuf. Technol. 16, 902–908 (2000)

Adams, J., Balas, E., Zawack, D.: The shifting bottle neck procedure for job shop scheduling. Manag. Sci 34, 391–407 (1998)

Fichera, V., Grusso, S., Lambordo, A. Genetic efficiency on flow shop. 10th International Conference on application of AI in Engineering 261–270 (1995)

Brandimart, P., Ukovich, W., Villa, A.: Continuous flow for batch manufacturing basis for a hierarchical approach.. Int. J. Prod. Res. 33, 1635–1660 (1995)

Park, L., Park, C.H.: Application of ga to job-shop scheduling problems with active schedule contracture crossover. Proceeding if the IEEE International Conference in system Man & Cyberneties 1, 53u-535 (1995)

Perrune, G., La Commare, U., Lo Nigro, G., Nuccto, C.: Dynamic scheduling in a multiple objective production environmemt using a fuzzy adaptive controller. Proceedings of the 11th international conference on computer aided production Engg, London 143–148 (1995)

Wang, L.C.: Inelegant scheduling of FMSS with indirective learning capability using neural networks. Int. J. FMSS 7, 147–175 (1995)

Duffre, N.A., Prabhu, V.V.: Real time distributed scheduling heterarchical manufacturing system. J. Manuf. Syst. 13, 94–107 (1994)

Gen, M., Tsujimura, Y., Kubota, E.: Solving job-shop scheduling problems by genetic algorithm. Proceeding if the IEEE International Conference on Systems Man –and Cyberneties 2, 1577-1582 (1994)

Rabelo, L.C., Jones, A., Yih, Y.: Development of a real-time learning Scheduler using Reinforcement learning concepts. Proceedings of the IEEE Int Symbesium un intelligent control 291–296 (1994)

Sridher, J., Rajendran, C.: Genetic algorithm for family & shop scheduling in a flow line based manufacturing cell. Comp Ind Eng 27, 469–472 (1994)

Suresh, V., Chaudhari, D.: Dynamic scheduling-A scheduling algorithm in FMS. Int. J. Prod. Econ. 32, 53–63 (1993)

Forrest, S.: Genetic algorithm principles of natural selection applied to computation. Science 261, 872–878 (1993)

Ishii, N., Talevage, J.J.: A transient based real time scheduling algorithm in FMS. Int. J. Prod. Res. 29, 2507–2520 (1991)

Syswerda, G.: Scheduling optimization using Gas. Handbook of gas 332–349 (1991)

Ramasesh, R.: Dynamic job shop scheduling: a survey of simulation research. Int. J. Manag. Sci. 18, 43–57 (1990)

Goldberg, D.E.: Genetic algorithm in search, optimization and machine learning. Addrson-Wesley, Reading (1989)

Booker, L.B., Goldberg, D.E., Holland, J.H.: Classifier systems and genetic algorithm. Artif. Intell. 40, 235–282 (1989)

Papadimitriou, C.H., Steiglitz, K.: Combinatorial optimaization: algorithm and complexity, pp. 310–312. Prentice Hall, Englewood Cliffs (1982)

Holland, J.H.: Adaptation in natural artificial systems. University of Michigan Press, Ann Arbor (1975)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, M.V., Murthy, A.N.N. & Chandrasekhara, K. Dynamic scheduling of flexible manufacturing system using heuristic approach. OPSEARCH 48, 1–19 (2011). https://doi.org/10.1007/s12597-011-0041-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12597-011-0041-6