Abstract

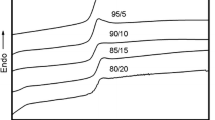

Binary and ternary blends comprised of polypropylene (PP), polystyrene (PS) and polystyrene-block-poly(ethylene-ran-butylene)-block-polystyrene (SEBS) were prepared. The effect of phase composition of minor components on the morphology, mechanical, viscoelastic, crystallization, and thermal degradation properties was studied. Binary blends exhibited inferior properties, typical of immiscible and incompatible multi-phase systems and showed matrix-droplet phase morphologies. Ternary blends, especially those with greater concentration of SEBS minor phase, exhibited interesting properties. Scanning electron micrographs of SEBS compatibilized PP/PS blends, did not show any PS particle pulling out of the PP matrix, indicating good compatibility of SEBS with PP/PS blends. Dynamic mechanical analysis also supported the heterogeneous phase structure of the blends. Thermogravimetry and differential scanning calorimetry showed that addition of PS and SEBS decreased the thermal stability of PP marginally, but shows slight variations in melting and crystallization behavior.

Similar content being viewed by others

References

Utracki Leszek A, Mukhopadhyay P, Gupta RK (2014) Chapter 1, Polymer blends introduction. In: Utracki Leszek A, Wilkie Charles A (eds) Polymer blends handbook, 2nd edn. Springer, NY

Vuluga Z, Panaitescu DM, Radovici C, Nicolae C, Iorga MD (2012) Effect of SEBS on morphology, thermal, and mechanical properties of PP/organoclay nanocomposites. Polym Bull 69:1073–1091

Azizi A, Arefazar A, Jazani OM (2013) Effects of core-shell particles on fracture micromechanisms of PP/PC/SEBS ternary blends. Polym Plast Technol Eng 52:1595–1603

Drozdov AD, Sanporean CG, Christiansen JDC (2014) Enhancement of mechanical properties of polypropylene by blending with styrene- (ethylene-butylene)-styrene tri-block copolymer. J Polym Eng 34:765–774

Sharma R, Maiti SN (2014) Effects of crystallinity of PP and flexibility of SEBS-g-MA copolymer on the mechanical properties of PP/SEBS-g-MA blends. Polym Plast Technol Eng 53:229–238

Azizi A, Arefazar A, Jazani OM (2014) Fracture micromechanisms of polypropylene/polycarbonate/poly(styrene-b-(ethylene-co-butylene)-b-styrene) (PP/PC/SEBS) ternary blends: the effects of SEBS content. J Macromol Sci B Phys 53:1103–1115

Sharma R, Maiti SN (2015) Effects of crystallinity of polypropylene (PP) on the mechanical properties of PP/styrene-ethylene-butylene-styrene-g-maleic anhydride (SEBS-g-MA)/teak wood flour (TWF) composites. Polym Bull 72:627–643

Lyu S (2003) Block copolymers suppressing droplet coalescence through stopping film rupture. Macromolecules 36:10052–10055

Sundararaj U (2006) Phase morphology development in polymer blends: processing and experimental aspects. In: Harrats C, Thomas S, Groeninckx G (eds) Micro- and nanostructured multiphase polymer blend systems: phase morphology and interfaces. Taylor & Francis Group, Boca Raton, pp 133–164

Huang H (2011) Macro-micro and nanostructured morphologies of multiphase polymer systems, Chapter 6. In: Boudenne A, Ibos L, Candau Y, Thomas S (eds) Handbook of multiphase polymer systems, vol 1. Wiley, New York, pp 151–249

Jose S, Thomas S, Biju PK, Kargr-Kocsis J (2013) Mechanical and dynamic mechanical properties of polyolefin blends: effect of blend ratio and copolymer monomer fraction on the compatibilisation efficiency of random copolymers. J Polym Res 20:303–316

Parameswarnpillai J, Joseph G, Chellappan RV, Zachakariah AK, Hameed N (2015) The effect of polypropylene-graft-maleic anhydride on the morphology and dynamic mechanical properties of polypropylene/polystyrene blends. J Polym Res 22:1–11

Parameswaranpillai J, Joseph G, Jose S, Hameed N (2015) Phase morphology, thermomechanical, and crystallization behavior of uncompatibilized and PP-g-MAH compatibilized polypropylene/polystyrene blends. J Appl Polym Sci 132:42100

Dı´az MF, Barbosa SE, Capiati NJ (2005) Improvement of mechanical properties for PP/PS blends by in situ compatibilization. Polymer 46:6096–6101

Waldman WR, De Paoli MA (2008) Photodegradation of polypropylene/polystyrene blends: styrene–butadiene–styrene compatibilisation effect. Polym Degrad Stabil 93:273–280

Al-Saleh MH, Sundararaj U (2008) Nanostructured carbon black filled polypropylene/polystyrene blends containing styrene–butadiene–styrene copolymer: influence of morphology on electrical resistivity. Eur Polym J 44:1931–1939

Li Y, Hu S, Sheng J (2007) Evolution of phase dimensions and interfacial morphology of polypropylene/polystyrene compatibilized blends during mixing. Eur Polym J 43:561–572

Lin BH, Du MC, Zhu YJ, Liang YW (2014) Non-isothermal crystallization behavior and kinetics of compatibilized β nucleated polypropylene/polystyrene blends. Adv Mater Res 893:291–294

de Freitas CA, Valera TS, de Souza AMC, Demarquette NR (2007) Morphology of compatibilized ternary blends. Macromol Symp 247:260–270

Wang D, Li Y, Xie XM, Guo BH (2011) Compatibilization and morphology development of immiscible ternary polymer blends. Polymer 52:191–200

Le Corroller P, Favis BD (2011) Effect of viscosity in ternary polymer blends displaying partial wetting phenomena. Polymer 52:3827–3834

Ravati S, Favis BD (2013) Tunable morphologies for ternary blends with poly(butylene succinate): partial and complete wetting phenomena. Polymer 54:3271–3281

Rastin H, Jafari SH, Saeb MR, Khonakdar HA, Wagenknecht U, Heinrich G (2014) On the reliability of existing theoretical models in anticipating type of morphology and domain size in HDPE/PA-6/EVOH ternary blends. Eur Polym J 53:1–12

Kolahchi AR, Ajji A, Carreau PJ (2014) Surface morphology and properties of ternary polymer blends: effect of the migration of minor components. J Phys Chem B 118:6316–6323

Dou R, Wang W, Zhou Y, Li L, Gong L, Yin B, Yang M (2013) Effect of core-shell morphology evolution on the rheology, crystallization, and mechanical properties of PA6/EPDM-g-MA/HDPE ternary blend. J Appl Polym Sci 129:253–262

Abreu FOMS, Forte MMC, Liberman SA (2005) SBS and SEBS block copolymers as impact modifiers for polypropylene compounds. J Appl Polym Sci 95:254–263

Parameswaranpillai J, Joseph G, Shinu KP, Sreejesh PR, Jose S, Salim NV, Hameed N (2015) The role of SEBS in tailoring the interface between the polymer matrix and exfoliated graphene nanoplatelets in hybrid composites. Mater Chem Phys 163:182–189

Parameswaranpillai J, Joseph G, Shinu KP, Jose S, Salim NV, Hameed N (2015) Development of hybrid composites for automotive applications: effect of addition of SEBS on the morphology, mechanical, viscoelastic, crystallization and thermal degradation properties of PP/PS–xGnP composites. RSC Adv 33:25634–25641

Van der Wal A, Mulder JJ, Gaymans RJ (1998) Fracture of polypropylene: the effect of crystallinity. Polymer 39:5477–5481

Karger-Kocsis J, Kalló A, Szafner A, Bodor G, Zs Sényei (1979) Morphological study on the effect of elastomeric impact modifiers in polypropylene systems. Polymer 20:37–43

Tortorella N, Beatty CL (2008) Morphology and mechanical properties of impact modified polypropylene blends. Polym Eng Sci 48:2098–2110

Macau´bas PHP, Demarquette NR (2001) Morphologies and interfacial tensions of immiscible polypropylene/polystyrene blends modified with triblock copolymers. Polymer 42:2543–2554

Ismail HH, Nasir M (2002) Morphological studies of uncompatibilized and compatibilized polystyrene/polypropylene blend. Polym Test 21:263–267

Wildes G, Keskkula H, Paul DR (1999) Coalescence in PC/SAN blends: effect of reactive compatibilization and matrix phase viscosity. Polymer 40:5609–5621

Welander M, Rigdahl M (1989) Use of an emulsifying block copolymer to improve time-dependent mechanical properties of polyethylene-polystyrene blends. Polymer 30:207–212

Manglio G, Palumbo R (1984) Polymer blends, processing, morphology and properties. Plenum press, New York, p 41

Bassani A, Pessan LA, Hage E (2001) Toughening of polypropylene with styrene/ethylene-butylene/styrene tri-block copolymer: effects of mixing condition and elastomer content. J Appl Polym Sci 82:2185–2193

Mcgrath GC, Fracture and toughening in fiber reinforced polymer composites, in rubber toughened engineering plastics, Chapman & hall, 1994, 61

Balkan O, Demirer H, Kayali ES (2011) Effects of deformation rates on mechanical properties of PP/SEBS blends. J Achiev Mater Manuf Eng 47:26–33

Brostow W, Grguric TH, Olea-Mejia O, Pietkiewicz D, Rek V (2008) Polypropylene + polystyrene blends with a compatibilizer. Part 2. Tribological and mechanical properties. e-Polymers, no. 034

Samsudin SA, Hassan A, Mokhtar M, Jamaluddin SMS (2005) Effect of SEBS on the mechanical properties and miscibility of polystyrene rich polystyrene/polypropylene blends. Prog Rubber Plast Recycl Technol 21:261–276

Ahmad Z, Kumar KD, Saroop M, Preschilla N, Biswas A, Bellare JB, Bhowmick AK (2010) Highly transparent thermoplastic elastomer from isotactic polypropylene and styrene/ethylene-butylene/styrene triblock copolymer: structure-property correlations. Polym Eng Sci 50:331–341

Zhao X, Huang Y, Kong M, Yang Q, Li G (2014) Retarded stress and morphology relaxation of deformed polymer blends in the presence of a triblock copolymer. RSC Adv 4:59302–59309

Liao CZ, Tjong SC (2011) Effects of carbon nanofibers on the fracture, mechanical, and thermal properties of PP/SEBS-g-MA blends. Polym Eng Sci 51:948–958

Acknowledgements

J P acknowledges the Department of Science and Technology, Government of India, for financial support under an Innovation in Science Pursuit for Inspired Research (INSPIRE) Faculty Award (contract Grant Number IFA-CH-16).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Parameswaranpillai, J., Jose, S., Siengchin, S. et al. Phase morphology, mechanical, dynamic mechanical, crystallization, and thermal degradation properties of PP and PP/PS blends modified with SEBS elastomer. Int J Plast Technol 21, 79–95 (2017). https://doi.org/10.1007/s12588-017-9172-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12588-017-9172-9