Abstract

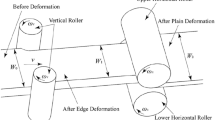

The objectives of this study were to analyze the width changes about the head and tail ends of the slab occurring during vertical–horizontal rolling using finite element (FE) analysis, and to derive an appropriate short stroke control (SSC) model for vertical–horizontal rolling based on the results of analyses. The relationship between the process variables and slab deformation about the head and tail ends, including width shrinkage and length of width shrinkage, was derived using the linear regression method. From considering the amount of slab deformation, an advanced SSC model for vertical–horizontal rolling process has been developed. The proposed SSC model was verified via an FE simulation. Vertical rolling simulations were performed using the roll gap that was calculated via the respective SSC model for each steel slab. Horizontal rolling simulations were also conducted. Cropping lengths about the head and tail ends that were regulated by width control standards of the specific work site were compared.

Similar content being viewed by others

References

Lee, K. H., Han, J. Q., Park, J. H., Kim, B. M., & Ko, D. C. (2015). Prediction and control of front-end curvature in hot finish rolling process. Advances in Mechanical Engineering,7(11), 1–10.

Xiong, S. W., Liu, X. H., & Wang, G. D. (2000). Analysis of non-steady state edging in roughing trains by a three-dimensional rigid-plastic finite element method. International Journal of Machine Tools and Manufacture,40(11), 1573–1585.

Chun, M. S., Cheong, J. S., An, I. T., & Moon, Y. H. (2003). Finite element analysis of slab deformation under the width reduction in hot strip mill. Transactions of Materials Processing,17(7), 668–674.

Yu, H. L., Liu, X. H., Li, C. S., & Wang, G. D. (2007). Influence of dog-bone apex on shape during slab horizontal rolling process. Journal of Iron and Steel Research International,14(3), 38–42.

Zang, X. L., Li, X. T., & Du, F. S. (2009). Head and tail shape control in vertical–horizontal rolling process by FEM. Journal of Iron and Steel Research International,16(5), 35–42.

Du, X. Z., Yang, Q., Li, C., Wang, A. L., & Tieu, A. K. (2010). Optimization of short stroke control preset for automatic width control of hot rolling mill. Journal of Iron and Steel Research International,17(6), 16–20.

Tan, S. B., Li, L., & Liu, J. C. (2011). Research on the gap setting model of short stroke control system in hot edge rolling. In 2011 Chinese control and decision conference (pp. 4126–4128).

Mohammad, R. F., Iman, S., & Amir, H. A.-S. (2009). A comparative study of slab deformation under heavy width reduction by sizing press and vertical rolling using FE analysis. Journal of Materials Processing Technology,209(2), 728–736.

Yun, D. J., & Hwang, S. M. (2012). Dimensional analysis of edge rolling for the prediction of the dog-bone shape. Transactions of Materials Processing,21(1), 24–29.

Li, X., Wang, H. Y., Ding, J. G., Xu, J. J., & Zhang, D. H. (2015). Analysis and prediction of fishtail during V-H hot rolling process. Journal of Central South University,22(4), 1184–1190.

Jeon, J. B. (2017). Study for improving width precision at the head and tail of slab in hot vertical–horizontal rolling. MD Thesis, Pusan National University, South Korea.

Ginzburg, V. B. (1989). Steel-rolling technology: Theory and practice (pp. 22–24). New York: Marcel Dekker Inc.

Rasti, J., Najafizadeg, A., & Meratian, M. (2011). Correcting the stress-strain curve in hot compression test using finite element analysis and Taguchi method. International Journal of Iron & Steel Society of Iran,8(1), 26–33.

Okado, M., Ariizumi, T., Noma, Y., Yabuuchi, K., & Yamazaki, Y. (1981). Width behavior of head and tail of slabs at edge rolling in hot strip mills. Journal of Iron and Steel Institute of Japan, 67(15), 2516–2525.

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) Grant funded by the Korea government (MSIP; Ministry of Science, ICT & Future Planning) (No. 2017R1C1B5017016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper was presented at PRESM2019.

Rights and permissions

About this article

Cite this article

Kim, BM., Lee, KH. & Jeon, JB. Short Stroke Control Model for Improving Width Precision at Head and Tail of Slab in Hot Vertical–Horizontal Rolling Process. Int. J. Precis. Eng. Manuf. 21, 699–710 (2020). https://doi.org/10.1007/s12541-019-00293-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00293-9