Abstract

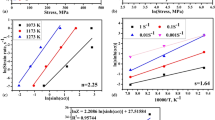

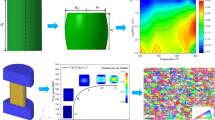

Accurate flow behaviors characterization plays a decisive role in the design and optimization of hot plastic forming processes with finite element method (FEM). In this study, the hot compression tests at elevated temperature were performed on a Gleeble 3500 thermo-physical test machine to acquire the true stress-strain data of GH4169 superalloy. Subsequently, an artificial neural network (ANN) with back-propagation algorithm was employed to learn the experimental true stress-strain data and then predict the constitutive relationships outside experimental conditions. It was revealed that the ANN can precisely track and predict the flow behaviors of GH4169 superalloy. The optimally-constructed and well-trained ANN model was written into a general finite element (FE) software platform via a user defined material subroutine programmed in Fortran language. Finally, the simulated hot compression tests with the FE model implanted ANN model were conducted. The intercomparisons between the experimental and simulated stroke-load curves revealed that integration of FEM with ANN is a feasible approach to conduct quality numerical computation for the varied hot plastic forming processes.

Similar content being viewed by others

References

Yang, X., Li, W., Ma, J., Hu, S., He, Y., et al., “Thermo-Physical Simulation of the Compression Testing for Constitutive Modeling of GH4169 Superalloy during Linear Friction Welding,” Journal of Alloys and Compounds, Vol. 656, pp. 395–407, 2016.

Chen, G., Zhang, Y., Xu, D., Lin, Y., and Chen, X., “Low Cycle Fatigue and Creep-Fatigue Interaction Behavior of Nickel-Base Superalloy GH4169 at Elevated Temperature of 650°C,” Materials Science and Engineering: A, Vol. 655, pp. 175–182, 2016.

Hu, D., Mao, J., Song, J., Meng, F., Shan, X., and Wang, R., “Experimental Investigation of Grain Size Effect on Fatigue Crack Growth Rate in Turbine Disc Superalloy GH4169 Under Different Temperatures,” Materials Science and Engineering: A, Vol. 669, pp. 318–331, 2016.

Abbasi, S. M. and Shokuhfar, A., “Prediction of Hot Deformation Behaviour of 10Cr-10Ni-5Mo-2Cu Steel,” Materials Letters, Vol. 61, Nos. 11-12, pp. 2523–2526, 2007.

Mao, P. L., Su, G. Y., and Yang, K., “Dynamic Recrystallisation of as Cast Austenite in 18-8 Stainless Steel,” Materials Science and Technology, Vol. 18, No. 8, pp. 892–896, 2002.

Liu, Y., Ning, Y., Nan, Y., Liang, H., Li, Y., and Zhao, Z., “Characterization of Hot Deformation Behavior and Processing Map of FGH4096-GH4133B Dual Alloys,” Journal of Alloys and Compounds, Vol. 633, pp. 505–515, 2015.

Samantaray, D., Mandal, S., Bhaduri, A., Venugopal, S., and Sivaprasad, P., “Analysis and Mathematical Modelling of Elevated Temperature Flow Behaviour of Austenitic Stainless Steels,” Materials Science and Engineering: A, Vol. 528, Nos. 4-5, pp. 1937–1943, 2011.

Wei, G., Peng, X., Hadadzadeh, A., Mahmoodkhani, Y., Xie, W., et al., “Constitutive Modeling of Mg-9Li-3Al-2Sr-Y at Elevated Temperatures,” Mechanics of Materials, Vol. 89, pp. 241–253, 2015.

Chen, L., Zhao, G., Yu, J., and Zhang, W., “Constitutive Analysis of Homogenized 7005 Aluminum Alloy at Evaluated Temperature for Extrusion Process,” Materials & Design (1980-2015), Vol. 66, Part A, pp. 129–136, 2015.

Ayala, H. V. H., Habineza, D., Rakotondrabe, M., Klein, C. E., and Coelho, L. S., “Nonlinear Black-Box System Identification through Neural Networks of a Hysteretic Piezoelectric Robotic Micromanipulator,” IFAC-PapersOnLine, Vol. 48, No. 28, pp. 409–414, 2015.

Yao, X., “Evolving Artificial Neural Networks,” Proceedings of the IEEE, Vol. 87, No. 9, pp. 1423–1447, 1999.

Bilgehan, M. and Turgut, P., “Artificial Neural Network Approach to Predict Compressive Strength of Concrete through Ultrasonic Pulse Velocity,” Research in Nondestructive Evaluation, Vol. 21, No. 1, pp. 1–17, 2010.

Liu, J., Chang, H., Hsu, T., and Ruan, X., “Prediction of the Flow Stress of High-Speed Steel during Hot Deformation using a BP Artificial Neural Network,” Journal of Materials Processing Technology, Vol. 103, No. 2, pp. 200–205, 2000.

Sabokpa, O., Zarei-Hanzaki, A., Abedi, H., and Haghdadi, N., “Artificial Neural Network Modeling to Predict the High Temperature Flow Behavior of an AZ81 Magnesium Alloy,” Materials & Design, Vol. 39, pp. 390–396, 2012.

Mandal, S., Sivaprasad, P., Venugopal, S., and Murthy, K., “Artificial Neural Network Modeling to Evaluate and Predict the Deformation Behavior of Stainless Steel Type AISI 304L during Hot Torsion,” Applied Soft Computing, Vol. 9, No. 1, pp. 237–244, 2009.

Phaniraj, M. P. and Lahiri, A. K., “The Applicability of Neural Network Model to Predict Flow Stress for Carbon Steels,” Journal of Materials Processing Technology, Vol. 141, No. 2, pp. 219–227, 2003.

Reddy, N. S., Lee, Y.-H., Kim, J. H., and Lee, C. S., “High Temperature Deformation Behavior of Ti-6Al-4V Alloy with and Equiaxed Microstructure: A Neural Networks Analysis,” Metals and Materials International, Vol. 14, No. 2, pp. 213, 2008.

Sun, Y., Zeng, W.-D., Zhao, Y.-Q., Zhang, X.-m., Ma, X., and Han, Y.-F., “Constructing Processing Map of Ti40 Alloy Using Artificial Neural Network,” Transactions of Nonferrous Metals Society of China, Vol. 21, No. 1, pp. 159–165, 2011.

Aoki, K. and Izumi, O., “Flow and Fracture Behaviour of Ni3 (Al·Ti) Single Crystals Tested in Tension,” Journal of Materials Science, Vol. 14, No. 8, pp. 1800–1806, 1979.

Zhu, Y., Zeng, W., Sun, Y., Feng, F., and Zhou, Y., “Artificial Neural Network Approach to Predict the Flow Stress in the Isothermal Compression of As-Cast TC21 Titanium Alloy,” Computational Materials Science, Vol. 50, No. 5, pp. 1785–1790, 2011.

Meissner, M., Schmuker, M., and Schneider, G., “Optimized Particle Swarm Optimization (OPSO) and Its Application to Artificial Neural Network Training,” BMC Bioinformatics, Vol. 7, No. 1, Paper No. 125, 2006.

Mandal, S., Rakesh, V., Sivaprasad, P., Venugopal, S., and Kasiviswanathan, K., “Constitutive Equations to Predict High Temperature Flow Stress in a Ti-Modified Austenitic Stainless Steel,” Materials Science and Engineering: A, Vol. 500, Nos. 1-2, pp. 114–121, 2009.

Ermis, K., Midilli, A., Dincer, I., and Rosen, M. A., “Artificial Neural Network Analysis of World Green Energy Use,” Energy Policy, Vol. 35, No. 3, pp. 1731–1743, 2007.

Vickram, A., Das, R., Srinivas, M., Rao, K. A., Jayaraman, G., and Sridharan, T., “Prediction of Zn Concentration in Human Seminal Plasma of Normospermia Samples by Artificial Neural Networks (ANN),” Journal of Assisted Reproduction and Genetics, Vol. 30, No. 4, pp. 453–459, 2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, X., Deng, L., Zhang, X. et al. Accurate Numerical Computation of Hot Deformation Behaviors by Integrating Finite Element Method with Artificial Neural Network. Int. J. Precis. Eng. Manuf. 19, 395–404 (2018). https://doi.org/10.1007/s12541-018-0047-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-018-0047-6