Abstract

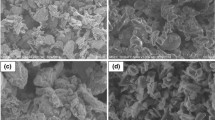

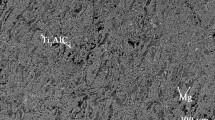

The dry sliding wear tests were performed for 10 vol.% (TiB+TiC)/Ti-6Al-4V matrix composites at various test conditions. The morphology and phases of worn surfaces and cross-sectional surfaces were investigated by using scanning electron microscopy (SEM) and X-ray diffraction (XRD). The wear loss of composites with the increase of load, but the wear behavior got more complex when the sliding speed and ambient temperature got higher. Low wear loss was achieved at lower sliding speed with higher temperature or higher sliding speed with lower temperature. A tribo-layer was always formed on worn surface during testing. It possessed different features and thus presented different effects during sliding wear. Meanwhile, the TiB and TiC particulates strengthened the Ti-6Al- 4V matrix, which increased the thermal stability of composites and postponed the occurrence of severe plastic deformation. In the mild wear region, those particulates could directly resist wear by reducing adhesive wear. In the steady stage, fractured TiB and TiC particulates participated in forming the tribo-layer together with wear debris, which effectively hindered the plastic deformation and thermal softening of the matrix. Experiment results suggest that the existence of different characteristic tribo-layers would result in the variation of wear behavior.

Similar content being viewed by others

References

Mao, Y. S., Wang, L., Chen, K. M., Wang, S. Q., and Cui, X. H., “Tribo-Layer and Its Role in Dry Sliding Wear of Ti-6Al-4V Alloy,” Wear, Vol. 297, No. 1, pp. 1032–1039, 2013.

Straffelini, G. and Molinari, A., “Dry Sliding Wear of Ti-6Al-4V Alloy as Influenced by the Counterface and Sliding Conditions,” Wear, Vol. 236, No. 1, pp. 328–338, 1999.

Fellah, M., Labaïz, M., Assala, O., Dekhil, L., Taleb, A., et al., “Tribological Behavior of Ti-6Al-4V and Ti-6Al-7Nb Alloys for Total Hip Prosthesis,” Advances in Tribology, Vol. 2014, Article ID: 451387, 2014.

Wendler, B. G. and Pawlak, W., “Low Friction and Wear Resistant Coating Systems on Ti-6Al-4V Alloy,” Journal of Achievements in Materials and Manufacturing Engineering, Vol. 26, No. 2, pp. 207–210, 2008.

Li, A., Zhao, J., Gao, X., and Wang, F., “Performance Evaluation of Ultra-Fine Grain Carbide in High-Speed Milling of Ti-6Al-4V,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 4, pp. 593–600, 2014.

Park, K.-H., Suhaimi, M. A., Yang, G.-D., Lee, D.-Y., Lee, S.-W., and Kwon, P., “Milling of Titanium Alloy with Cryogenic Cooling and Minimum Quantity Lubrication (MQL),” Int. J. Precis. Eng. Manuf., Vol. 18, No. 1, pp. 5–14, 2017.

Lee, C.-M., Woo, W.-S., Baek, J.-T., and Kim, E.-J., “Laser and Arc Manufacturing Processes: A Review,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 7, pp. 973–985, 2016.

Quan, G.-z., Wen, H.-r., and Zou, Z.-y., “Construction of Processing Maps Based on Expanded Data by BP-ANN and Identification of Optimal Deforming Parameters for Ti-6Al-4V Alloy,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 2, pp. 171–180, 2016.

Choi, H.-J., Park, C.-W., Kang, I.-S., Kim, J.-S., and Choi, S.-D., “Material Model Application Considering Strain Softening for Cutting Simulation of Ti-6Al-4V Alloy and Its Experimental Validation,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 12, pp. 1651–1658, 2016.

Dong, H. and Bell, T., “Enhanced Wear Resistance of Titanium Surfaces by a New Thermal Oxidation Treatment,” Wear, Vol. 238, No. 2, pp. 131–137, 2000.

Bloyce, A., Qi, P.-Y., Dong, H., and Bell, T., “Surface Modification of Titanium Alloys for Combined Improvements in Corrosion and Wear Resistance,” Surface and Coatings Technology, Vol. 107, Nos. 2-3, pp. 125–132, 1998.

Vadiraj, A., Kamaraj, M., and Gnanamoorthy, R., “Fretting Wear Studies on Uncoated, Plasma Nitrided and Laser Nitrided Biomedical Titanium Alloys,” Materials Science and Engineering: A, Vols. 445-446, pp. 446–453, 2007.

Filip, R., “Laser Nitriding of the Surface Layer of Ti-6Al-4V Titanium Alloy,” Archives of Materials Science and Engineering, Vol. 30, No. 1, pp. 25–28, 2008.

Zhou, G., Ding, H., Zhang, Y., Liu, A., Lin, Y., and Zhu, Y., “Fretting Wear Study on Micro-Arc Oxidation TiO2 Coating on TC4 Titanium Alloys in Simulated Body Fluid,” Tribology Letters, Vol. 40, No. 3, pp. 319–326, 2010.

Lin, X.-Z., Zhu, M.-H., Zheng, J.-F., Jun, L., and Mo, J.-L., “Fretting Wear of Micro-Arc Oxidation Coating Prepared on Ti-6Al-4V Alloy,” Transactions of Nonferrous Metals Society of China, Vol. 20, No. 4, pp. 537–546, 2010.

Mahamood, R. M., Akinlabi, E. T., Shukla, M., and Pityana, S., “Scanning Velocity Influence on Microstructure, Microhardness and Wear Resistance Performance of Laser Deposited Ti-6Al-4V/TiC Composite,” Materials & Design, Vol. 50, pp. 656–666, 2013.

Han, C., Li, Y.-C., Liang, X.-G., Chen, L.-P., Zhao, N., and Zhu M.-K., “Effect of Composition and Sintering Temperature on Mechanical Properties of ZrO2 Particulate-Reinforced Titanium-Matrix Composite,” Transactions of Nonferrous Metals Society of China, Vol. 22, No. 8, pp. 1855–1859, 2012.

Kim, J.-S., Lee, K.-M., Cho, D.-H., and Lee, Y.-Z., “Fretting Wear Characteristics of Titanium Matrix Composites Reinforced by Titanium Boride and Titanium Carbide Particulates,” Wear, Vol. 301, No. 1, pp. 562–568, 2013.

Dalili, N., Edrisy, A., Farokhzadeh, K., Li, J., Lo, J., and Riahi, A., “Improving the Wear Resistance of Ti-6Al-4V/TiC Composites through Thermal Oxidation (TO),” Wear, Vol. 269, No. 7, pp. 590–601, 2010.

Wang, M.-M., Lu, W.-J., Qin, J.-N., Zhang, D., Ji, B., and Zhu, F., “Superplastic Behavior of in Situ Synthesized (TiB+TiC)/Ti Matrix Composite,” Scripta Materialia, Vol. 53, No. 2, pp. 265–270, 2005.

Choi, B. J., Hong, K. E., Youn, J. I., and Kim, Y. J., “In Situ Synthesis and Wear Resistance of Titanium Matrix Composites,” Advanced Materials Research, Vols. 89-91, pp. 107–111, 2010.

Kim, I., Choi, B., Kim, Y., and Lee, Y., “Friction and Wear Behavior of Titanium Matrix (TiB+ TiC) Composites,” Wear, Vol. 271, No. 9, pp. 1962–1965, 2011.

Xu, J. and El Mansori, M., “Cutting Modeling Using Cohesive Zone Concept of Titanium/CFRP Composite Stacks,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 10, pp. 2091–2100, 2015.

Xu, J. and El Mansori, M., “Numerical Modeling of Stacked Composite CFRP/Ti Machining Under Different Cutting Sequence Strategies,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 1, pp. 99–107, 2016.

Choi, B.-J., Kim, I.-Y., Lee, Y.-Z., and Kim, Y.-J., “Microstructure and Friction/Wear Behavior of (TiB+TiC) Particulate-Reinforced Titanium Matrix Composites,” Wear, Vol. 318, No. 1, pp. 68–77, 2014.

Zhou, H., Zhang, Y., Hua, X., and Yang, Z., “High-Temperature Anti-Wear Behavior of Alumina-Reinforced Ti-Zr-Mo Alloy Composites,” Wear, Vol. 319, No. 1, pp. 184–190, 2014.

Matsugi, K., Sasaki, G., Yanagisawa, O., Li, D., Kuramoto, H., and Oki, T., “Preparation of Ti Matrix Composites of Ti-BCN Systems by Spark Sintering and their Friction and Wear Characteristics,” Materials Transactions, Vol. 48, No. 5, pp. 1042–1049, 2007.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zi-Run, Y., Hai-Xiang, H., Jiang, CF. et al. Evaluation on dry sliding wear behavior of (TiB+TiC)/Ti-6Al-4V matrix composite. Int. J. Precis. Eng. Manuf. 18, 1139–1146 (2017). https://doi.org/10.1007/s12541-017-0133-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0133-1