Abstract

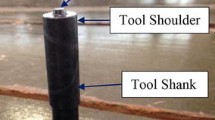

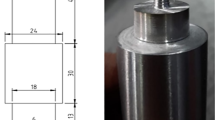

The effects of tool geometry and process parameters on the mechanical properties of friction stir spot welded (FSSW) dissimilar aluminum alloys are experimentally investigated. Two tools with different shoulder profiles, concave and convex, were considered. Two typical automotive aluminum alloys were selected for FSSW, thus resulting in two different material combinations for each shoulder profile. The experimental results showed that the two shoulder profiles caused significant differences in the axial force, the mixing of materials, and the mechanical properties of the joint. The sensitivity of joint strength to the variation of the tool rotation speed and the plunge speed was also quite dependent on the shoulder profile. The experimental result shows that the change of joint strength can be quite significant.

Similar content being viewed by others

References

Yuan, W., Mishra, R. S., Webb, S., Chen, Y., Carlson, B., et al., “Effect of Tool Design and Process Parameters on Properties of Al Alloy 6016 Friction Stir Spot Welds,” Journal of Materials Processing Technology, Vol. 211, No. 6, pp. 972–977, 2011.

Thornton, P., Krause, A., and Davies, R., “Aluminum Spot Weld,” Welding Journal-Including Welding Research Supplement, Vol. 75, No. 3, pp. 101s-108s, 1996.

Gean, A., Westgate, S. A., Kucza, J. C., and Ehrstrom, J. C., “Static and Fatigue Behavior of Spot-Welded 5182-0 Aluminum Alloy Sheet,” Welding Journal-New York-, Vol. 78, pp. 80s–86s, 1999.

Khan, M. I., Kuntz, M. I., Su, P., Gerlich, A., North, T. H., and Zhou, Y., “Resistance and Friction Stir Spot Welding of DP600: A Comparative Study,” Science and Technology of Welding and Joining, Vol. 12, No. 2, pp. 175–182, 2007.

Thomas, W. M., Nicholas, E. D., Needham, M. G., Murch, P., Temple-Smith, P., and Dawes, C. J., “'Friction Stir Butt Welding,” GB Patent, 9125978-8, 1991.

Kim, W.-K., Won, S.-T., and Goo, B.-C., “A Study on Mechanical Characteristics of the Friction Stir Welded A6005-T5 Extrusion,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 6, pp. 931–936, 2010.

Shojaeefard, M. H., Akbari, M., and Asadi, P., “Multi Objective Optimization of Friction Stir Welding Parameters Using FEM and Neural Network,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 11, pp. 2351–2356, 2014.

Saunders, N., Miles, M., Hartman, T., Hovanski, Y., Hong, S.-T., and Steel, R., “Joint Strength in High Speed Friction Stir Spot Welded DP 980 Steel,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 5, pp. 841–848, 2014.

Mishra, R. S. and Ma, Z., “Friction Stir Welding and Processing,” Materials Science and Engineering: R: Reports, Vol. 50, No. 1, pp. 1–78, 2005.

Mishra, R. S., Webb, S., Freeney, T., Chen, Y., Gayden, X., et al., “Friction Stir Spot Welding of 6016 Aluminum Alloy,” Proc. of Friction Stir Welding and Processing IV, pp. 341–348, 2007.

Fujimoto, M., Koga, S., Abe, N., Yutaka Sato, S., and Kokawa, H., “Analysis of Plastic Flow of the Al Alloy Joint Produced by Friction Stir Spot Welding,” Quarterly Journal of the Japan Welding Society, Vol. 26, No. 1, pp. 67–73, 2008. (in Japanese)

Gerlich, A., Su, P., Yamamoto, M., and North, T. H., “Material Flow and Intermixing during Dissimilar Friction Stir Welding,” Science and Technology of Welding and Joining, Vol. 13, No. 3, pp. 254–264, 2008.

Su, P., Gerlich, A., North, T. H., and Bendzsak, G. J., “Intermixing in Dissimilar Friction Stir Spot Welds,” Metallurgical and Materials Transactions A, Vol. 38, No. 3, pp. 584–595, 2007.

Yang, Q., Mironov, S., Sato, Y. S., and Okamoto, K., “Material Flow during Friction Stir Spot Welding,” Materials Science and Engineering: A, Vol. 527, No. 16, pp. 4389–4398, 2010.

Su, P., Gerlich, A., North, T. H., and Bendzsak, G. J., “Material Flow during Friction Stir Spot Welding,” Science and Technology of Welding And Joining, Vol. 11, No. 1, pp. 61–71, 2006.

Fujimoto, M., Koga, S., Abe, N., Sato, Y. S., and Kokawa, H., “Microstructural Analysis of the Stir Zone of Al Alloy Produced by Friction Stir Spot Welding,” Quarterly Journal of the Japan Welding Society, Vol. 25, No. 4, pp. 553–559, 2007.

Reynolds, A. P., “Flow Visualization and Simulation in FSW,” Scripta Materialia, Vol. 58, No. 5, pp. 338–342, 2008.

Arul, S. G., Pan, T., Lin, P.-C., Pan, J., Feng, Z., and Santella, M. L., “Microstructures and Failure Mechanisms of Spot Friction Welds in Lap-Shear Specimens of Aluminum 5754 Sheets,” SAE Technical Paper, No. 2005-01-1256, 2005.

Badarinarayan, H., Shi, Y., Li, X., and Okamoto, K., “Effect of Tool Geometry on Hook Formation and Static Strength of Friction Stir Spot Welded Aluminum 5754-O Sheets,” Int. J. Precis. Eng. Manuf., Vol. 49, No. 11, pp. 814–823, 2009.

Badarinarayan, H., Yang, Q., and Zhu, S., “Effect of Tool Geometry on Static Strength of Friction Stir Spot-Welded Aluminum Alloy,” Int. J. Precis. Eng. Manuf., Vol. 49, No. 2, pp. 142–148, 2009.

Arul, S. G., Miller, S. F., Kruger, G. H., Pan, T.-Y., Mallick, P. K., and Shih, A. J., “Experimental Study of Joint Performance in Spot Friction Welding of 6111-T4 Aluminium Alloy,” Science and Technology of Welding and Joining, Vol. 13, No. 7, pp. 629–637, 2008.

Abu, M., Hossain, M., Hasan, M. T., Hong, S.-t., Miles, M., et al., “Friction Stir Spot Welded Joints of 409L Stainless Steels Fabricated by a Convex Shoulder Tool,” Metals and Materials International, Vol. 19, No. 6, pp. 1243–1250, 2013.

Lacki, P., Kucharczyk, Z., Śliwa, R., and Gałaczyński, T., “Effect of Tool Shape on Temperature Field in Friction Stir Spot Welding,” Archives of Metallurgy and Materials, Vol. 58, No. 2, pp. 595–599, 2013.

Colegrove, P. A. and Shercliff, H. R., “Two-Dimensional CFD Modelling of Flow Round Profiled FSW Tooling,” Science and Technology of Welding and Joining, Vol. 9, No. 6, pp. 483–492, 2004.

Colegrove, P. A. and Shercliff, H. R., “Two-Dimensional CFD Modelling of Flow Round Profiled FSW Tooling,” Science and Technology of Welding and Joining, Vol. 9, No. 6, pp. 483–492, 2004.

Iordachescu, M., Scutelnicu, E., and Iordachescu, D., “Fundamentals of the Process and Tools Design: Friction Stir Processing of Materials,” The Annals of Dunarea de Jos University of Galati, Fascicle XII, Welding Equipment and Technology, Year, Vol. 17, pp. 63–72, 2006.

Nandan, R., DebRoy, T., and Bhadeshia, H., “Recent Advances in Friction-Stir Welding-Process, Weldment Structure and Properties,” Progress in Materials Science, Vol. 53, No. 6, pp. 980–1023, 2008.

Khan, M. I., Kuntz, M. L., Su, P., Gerlich, A., North, T., and Zhou, Y., “Resistance and Friction Stir Spot Welding of DP600: A Comparative Study,” Science and Technology of Welding and Joining, Vol. 12, No. 2, pp. 175–182, 2007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, JR., Ahn, EY., Das, H. et al. Effect of tool geometry and process parameters on mechanical properties of friction stir spot welded dissimilar aluminum alloys. Int. J. Precis. Eng. Manuf. 18, 445–452 (2017). https://doi.org/10.1007/s12541-017-0053-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0053-0