Abstract

In this study, cylindrical cup deep drawing of the high strength differential Tailor Welded Blank (TWB) consisting of Twinning-Induced Plasticity (TWIP) steel and low carbon steel (mild steel) was investigated using a finite element (FE) analysis. The strength ratio of TWIP to mild steel was about 4, which has not been investigated in previous researches. The formability of the TWB sheet was correlated to the weld-line movement and the thinning in the softer part of the TWB. From this virtual FE experiment, the inferior drawability of TWB when compared to monolithic blanks resulted from uncontrolled material flow. A modified tool design was proposed by adding the counter-punch concept to control the material flow near the weld-line. Then, the process parameters such as blank holding force, counter-punch force, friction conditions of punch-to-blank and counter-punch-to-blank were optimized using the Taguchi method. An improved tool design in combination with optimized process parameters improved the drawability of the TWB significantly.

Similar content being viewed by others

References

De Cooman, B. C., Chin, K. G., and Kim, J., “High Mn TWIP Steels for Automotive Applications,” New Trends and Developments in Automotive System Engineering, InTech, pp. 101–128, 2011.

Chung, K., Ahn, K., Yoo, D. H., Chung, K. H., Seo, M. H., and Park, S. H., “Formability of TWIP (Twinning Induced Plasticity) Automotive Sheets,” International Journal of Plasticity, Vol. 27, No. 1, pp. 52–81, 2011.

Chung, K., Ma, N., Park, T., Kim, D., Yoo, D., and Kim, C., “A Modified Damage Model for Advanced High Strength Steel Sheets,” International Journal of Plasticity, Vol. 27, No. 10, pp. 1485–1511, 2011.

Xu, L., Barlat, F., and Lee, M. G., “Hole Expansion of Twinning-Induced Plasticity Steel,” Scripta Materialia, Vol. 66, No. 12, pp. 1012–1017, 2012.

Keil, D., Zinke, M., and Pries, H., “Investigations on Hot Cracking of Novel High Manganese TWIP-Steels,” in Hot Cracking Phenomena in Welds III, pp. 209–223, 2011.

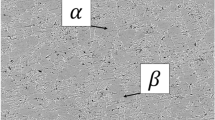

Mujica, L., Weber, S., Pinto, H., Thomy, C., and Vollertsen, F., “Microstructure and Mechanical Properties of Laser-Welded Joints of TWIP and TRIP Steels,” Materials Science and Engineering: A, Vol. 527, No. 7, pp. 2071–2078, 2010.

Bok, H. H., Lee, M. G., Pavlina, E. J., Barlat, F., and Kim, H. D., “Comparative Study of the Prediction of Microstructure and Mechanical Properties for a hot-Stamped B-Pillar Reinforcing Part,” International Journal of Mechanical Sciences, Vol. 53, No. 9, pp. 744–752, 2011.

Abbasi, M., Ketabchi, M., Labudde, T., Prahl, U., and Bleck, W., “New Attempt to Wrinkling behavior Analysis of tailor Welded Blanks during the Deep Drawing Process,” Materials & Design, Vol. 40, No. pp. 407–414, 2012.

Chen, W., Lin, G. S., and Hu, S. J., “A comparison Study on the Effectiveness of Stepped Binder and Weld Line Clamping Pins on Formability Improvement for tailor-Welded Blanks,” Journal of Materials Processing Technology, Vol. 207, No. 1, pp. 204–210, 2008.

Kinsey, B., Liu, Z., and Cao, J., “A Novel Forming Technology for Tailor-Welded Blanks,” Journal of Materials Processing Technology, Vol. 99, No. 1, pp. 145–153, 2000.

Saunders, F. I. and Wagoner, R. H., “Forming of Tailor-Welded Blanks,” Metallurgical and Materials Transactions A, Vol. 27, No. 9, pp. 2605–2616, 1996.

Shi, M. F., Pickett, K. M., and Bhatt, K. K., “Formability Issues in the Application of Tailor Welded Blank Sheets,” SAE Technical, Paper No. 930278, 1993.

Butuc, M. C., Teodosiu, C., Barlat, F., and Gracio, J. J., “Analysis of Sheet Metal Formability Through Isotropic and Kinematic Hardening Models,” European Journal of Mechanics-A/Solids, Vol. 30, No. 4, pp. 532–546, 2011.

Barlat, F., Brem, J. C., Yoon, J. W., Chung, K., Dick, R. E., and et al., “Plane Stress Yield Function for Aluminum Alloy Sheets-Part 1: Theory,” International Journal of Plasticity, Vol. 19, No. 9, pp. 1297–1319, 2003.

Narayanan, R. G. and Narasimhan, K., “Weld Region Representation during the Simulation of TWB Forming Behavior,” International Journal of Forming Processes, Vol. 9, No. 4, pp. 491, 2006.

Raymond, S. D., Wild, P. M., and Bayley, C. J., “On Modeling of the Weld Line in finite Element Analyses of Tailor-Welded Blank Forming Operations,” Journal of Materials Processing Technology, Vol. 147, No. 1, pp. 28–37, 2004.

Zhao, K. M., Chun, B. K., and Lee, J. K., “Finite Element Analysis of Tailor-Welded Blanks,” Finite Elements in Analysis and Design, Vol. 37, No. 2, pp. 117–130, 2001.

Saunders, F. I. and Wagoner, R. H., “The Use of Tailor-Welded Blanks in Automotive Applications,” Simulation of Materials Processing: Theory, Methods and Applications, pp. 157–164, 1995.

Meinders, T., Van den Berg, A., and Huetink, J., “Deep Drawing Simulations of Tailored Blanks and Experimental Verification,” Journal of Materials Processing Technology, Vol. 103, No. 1, pp. 65–73, 2000.

Reis, A., Teixeira, P., Ferreira Duarte, J., Santos, A., Barata da Rocha, A., and Fernandes, A., “Tailored Welded Blanks-an Experimental and Numerical Study in Sheet Metal Forming on the Effect of Welding,” Computers & structures, Vol. 82, No. 17, pp. 1435–1442, 2004.

PAM-STAMP, “PAM STAMP 2012 User’s Manuals,” https://www.esi-group.com/software-services/virtual-manufacturing/sheet-metalforming/stamping-solution-pam-stamp (Accessed 1 OCT 2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nguyen, NT., Hariharan, K., Barlat, F. et al. Design of high strength differential TWB to enhance drawability: FE study and optimization. Int. J. Precis. Eng. Manuf. 15, 2273–2283 (2014). https://doi.org/10.1007/s12541-014-0591-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-014-0591-7