Abstract

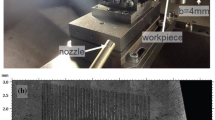

The present study seeks to realize an improved understanding of the action of cutting fluid through direct observation of the chip-tool interface. That is, using transparent tools made of sapphire in conjunction with a high-speed, CCD-based imaging system, the chip-tool contact condition and its evolution in the presence of cutting fluid are directly observed during 2-D orthogonal machining of pure lead and Al6061-T6. Then, spatial and temporal analysis of the images of the chip-tool interface is made for measuring the contact length and velocity profile along the tool rake face, and the contact conditions are correlated with the cutting forces measured. The results are compared with those made when cutting dry to clarify the effects of cutting fluid action, and a picture of the action of cutting fluid at the chip-tool interface is presented finally.

Similar content being viewed by others

References

Merchant, M. E., “Fundamentals of Cutting Fluid Action,” Lubrication Engineering, Vol. 6, No. 4, pp. 163–167, 1950.

Williams, J. A. and Tabor, D., “The Role of Lubricants in Machining,” Wear, Vol. 43, No. 3, pp. 275–292, 1977.

Huang, C., Lee, S., Sullivan, J. P., and Chandrasekar, S., “In Situ Measurement of Fluid Film Thickness in Machining,” Tribology Letters, Vol. 28, No. 1, pp. 39–44, 2007.

Bierla, A., Fromentin, G., Minfray, C., Martin, J. M., Le Mogne, T., and Genet, N., “Mechanical and Physico-Chemical Study of Sulfur Additives Effect in Milling of High Strength Steel,” Wear, Vol. 286, pp. 116–123, 2012.

Rowe, G. W. and Spick, P., “A New Approach to Determination of the Shear-Plane Angle in Machining,” Journal of Manufacturing Science and Engineering, Vol. 89, No. 3, pp. 530–538, 1967.

De Chiffre, L., “Mechanics of Metal Cutting and Cutting Fluid Action,” International Journal of Machine Tool Design and Research, Vol. 17, No. 4, pp. 225–234, 1977.

De Chiffre, L., “Lubrication in Cutting-Critical Review and Experiments with Restricted Contact Tools,” ASLE Transactions, Vol. 24, No. 3, pp. 340–344, 1981.

De Chiffre, L., “’Function of Cutting Fluids in Machining,” Lubrication Engineering, Vol. 44, No. 6, pp. 514–518, 1988.

Rehbinder, P., “New Physico-Chemical Phenomena in the Deformation and Mechanical Treatment of Solids,” Nature, Vol. 159, pp. 866–867, 1947.

Usui, E., Gujral, A., and Shaw, M. C., “An Experimental Study of the Action of CCL4 in Cutting and Other Processes Involving Plastic Flow,” International Journal of Machine Tool Design and Research, Vol. 1, No. 3, pp. 187–197, 1961.

Cassin, C. and Boothroyd, G., “Lubricating Action of Cutting Fluids,” Journal of Mechanical Engineering Science, Vol. 7, No. 1, pp. 67–81, 1965.

Naerheim, Y., Smith, T., and Lan, M. S., “Experimental Investigation of Cutting Fluid Interaction in Machining,” Journal of Tribology, Vol. 108, No. 3, pp. 364–367, 1986.

Horne, J. G., Doyle, E. D., and Tabor, D., “Direct Observation of Chip-Tool Interface in Metal Cutting,” Proc. of 5th NAMRC, pp. 237–240, 1997.

Doyle, E. D., Horne, J. G., and Tabor, D., “Frictional Interactions between Chip and Rake Face in Continuous Chip Formation,” Proceedings of the Royal Society of London. A. Mathematical and Physical Sciences, Vol. 366, No. 1725, pp. 173–183, 1979.

Madhavan, V., Chandrasekar, S., and Farris, T., “Direct Observations of the Chip-Tool Interface in the Low Speed Cutting of Pure Metals,” Journal of Tribology, Vol. 124, No. 3, pp. 617–626, 2002.

Ackroyd, B., Chandrasekar, S., and Compton, W., “A Model for the Contact Conditions at the Chip-Tool Interface in Machining,” Journal of Tribology, Vol. 125, No. 3, pp. 649–660, 2003.

Hwang, J. and Chandrasekar, S., “Contact Conditions at the Chip-Tool Interface in Machining,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 2, pp. 183–193, 2011.

Horne, J. G., Doyle, E. D., and Tabor, D., “Direct Observation of Contact and Lubrication at the Chip-Tool Interface,” Proc. of the 1st International Conference on Lubrication Challenges in Metalworking and Processing, pp. 566–574, 1978.

Kattwinkel, W., “Experimentation of Cutting Action by Means of Photoelasticity,” Industrie-Anzeiger, Vol. 36, pp. 525, 1957.

Usui, E. and Takeyama, H., “A Photoelastic Analysis of Machining Stresses,” Journal of Manufacturing Science and Engineering, Vol. 82, No. 4, pp. 303–307, 1960.

Chandrasekaran, H. and Kapoor, D., “Photoelastic Analysis of Tool-Chip Interface Stresses,” Journal of Manufacturing Science and Engineering, Vol. 87, No. 4, pp. 495–502, 1965.

Bagchi, A. and Wright, P., “Stress Analysis in Machining with the Use of Sapphire Tools,” Proceedings of the Royal Society of London. A. Mathematical and Physical Sciences, Vol. 409, No. 1836, pp. 99–113, 1987.

Bowden, F. P. and Tabor, D., “The Friction and Lubrication of Solids,” Oxford, 1986.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hwang, J. Direct observation of fluid action at the chip-tool interface in machining. Int. J. Precis. Eng. Manuf. 15, 2041–2049 (2014). https://doi.org/10.1007/s12541-014-0561-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-014-0561-0