Abstract

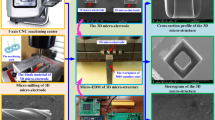

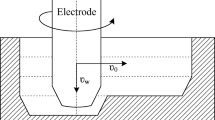

Fine surface finish of micro features processed by micro EDM is difficult due to small feature size. In this work, we investigated electrochemical finishing process after micro EDM. The product shape was machined by micro EDM, and the surface was finished by electrochemical process. For both processes, deionized water was only used as dielectric fluid for EDM and electrolyte for finishing. Surface formation characteristics during finishing and side gap increase were analyzed according to machining conditions. In addition, surface roughness and hardness were measured to compare three cases of surface processed by micro EDM in deionized water, by micro EDM in kerosene, and by finishing in deionized water after micro EDM, respectively. Micro grooves and pockets were fabricated by micro EDM milling and electrochemical finish. In the case of drilling, electrochemical finish in deionized water not only finished inner surface of the holes but also expanded entrance and exit hole size. Using this phenomenon, micro drawing die was fabricated by controlling finishing conditions.

Similar content being viewed by others

References

Chung, D. K., Shin, H. S., Park, M. S., Kim, B. H., and Chu, C. N., “Recent Researches in Micro Electrical Machining,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 2, pp. 371–380, 2011.

Takahata, K., Aoki, S., and Sato, T., “Fine Surface Finishing Method for 3-Dimensional Micro Structures,” Proc. of IEEE 9th International Workshop on Micro Electro Mechanical Systems, pp. 73–78, 1996.

Hung, J. C., Yan, B. H., Liu, H. S., and Chow, H. M., “Micro-Hole Machining using Micro-EDM Combined with Electropolishing,” Journal of Micromechanics and Microengineering, Vol. 16, No. 8, pp. 1480–1486, 2006.

Kunieda, M., Lauwers, B., Rajurkar, K., and Schumacher, B., “Advancing EDM through Fundamental Insight into the Process,” CIRP Annals-Manufacturing Technology, Vol. 54, No. 2, pp. 64–87, 2005.

Kunieda, M., Yoshida, M., and Taniguchi, N., “Electrical Discharge Machining in Gas,” CIRP Annals-Manufacturing Technology, Vol. 46, No. 1, pp. 143–146, 1997.

Song, K. Y., Chung, D. K., Park, M. S., and Chu, C. N., “Water Spray Electrical Discharge Drilling of WC-Co to Prevent Electrolytic Corrosion,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 7, pp. 1117–1123, 2012.

Rajurkar, K. P., Levy, G., Malshe, A., Sundaram, M. M., McGeough, J., et al., “Micro and Nano Machining by Electro-Physical and Chemical Processes,” CIRP Annals-Manufacturing Technology, Vol. 55, No. 2, pp. 643–666, 2006.

Chung, D. K., Shin, H. S., Kim, B. H., Park, M. S., and Chu, C. N., “Surface Finishing of Micro-EDM Holes using Deionized Water,” Journal of Micromechanics and Microengineering, Vol. 19, No. 4, Paper No. 045025, 2009.

Masuzawa, T., Kuo, C. L., and Fujino, M., “A Combined Electrical Machining Process for Micronozzle Fabrication,” CIRP Annals-Manufacturing Technology, Vol. 43, No. 1, pp. 189–192, 1994.

Nguyen, M. D., Rahman, M., and Wong, Y. S., “Simultaneous Micro-EDM and Micro-ECM in Low-Resistivity Deionized Water,” International Journal of Machine Tools and Manufacture, Vol. 54, No. pp. 55–65, 2012.

Masuzawa, T., Fujino, M., Kobayashi, K., Suzuki, T., and Kinoshita, N., “Wire Electro-Discharge Grinding for Micro-Machining,” CIRP Annals-Manufacturing Technology, Vol. 34, No. 1, pp. 431–434, 1985.

Lee, E. S., “Machining Characteristics of the Electropolishing of Stainless Steel (STS316L),” The International Journal of Advanced Manufacturing Technology, Vol. 16, No. 8, pp. 591–599, 2000.

Chung, D. K., Kim, B. H., and Chu, C. N., “Micro Electrical Discharge Milling using Deionized Water as a Dielectric Fluid,” Journal of Micromechanics and Microengineering, Vol. 17, No. 5, pp. 867–874, 2007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chung, D.K., Lee, K.H., Jeong, J. et al. Machining characteristics on electrochemical finish combined with micro EDM using deionized water. Int. J. Precis. Eng. Manuf. 15, 1785–1791 (2014). https://doi.org/10.1007/s12541-014-0530-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-014-0530-7