Abstract

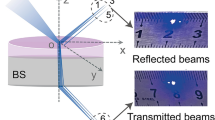

We developed a maskless lithography system using a digital micromirror device (DMD). This system incorporates a light-emitting diode (LED) driver to generate ultraviolet (UV) light, illumination optics using a fly-eye lens, and telecentric projection optics to generate a parallel light source reflected from the DMD. The potential problems caused by using a mask (e.g., increased expense, increased time for processing, contamination, and alignment problems) can be circumvented with the proposed maskless system. Exposure energy intensity and the micropattern-generating performance were tested with the developed system. To investigate the performance of the developed system, a passive micromixer was fabricated using the soft lithography process. The molds for the micromixer were fabricated using the proposed DMD system and a conventional UV lithography system. Mixing experiments were performed in order to compare the performance of the micromixers fabricated using both approaches. The surface texture of the micromixer fabricated by the DMD system induced more vortex flow in the channel and thus the micromixer showed approximately 10% higher mixing performance.

Similar content being viewed by others

References

Del Campo, A. and Greiner, C., “SU-8: a Photoresist for High-Aspect-Ratio and 3D Submicron Lithography,” Journal of Micromechanics and Microengineering, Vol. 17, No. 6, pp. R81–R95, 2007.

Singh-Gasson, S., Green, R. D., Yue, Y., Nelson, C., Blattner, F., Sussman, M. R., and Cerrina, F., “Maskless Fabrication of Light-Directed Oligonucleotide Microarrays using a Digital Micromirror Array,” Nature Biotechnology, Vol. 17, No. 10, pp. 974–978, 1999.

Kessels, M. V., Nassour, C., Grosso, P., and Heggarty, K., “Direct Write of Optical Diffractive Elements and Planar Waveguides with a Digital Micromirror Device based UV Photoplotter,” Optics Communications, Vol. 283, No. 15, pp. 3089–3094, 2010.

Sun, C., Fang, N., Wu, D., and Zhang, X., “Projection Micro-Stereolithography using Digital Micro-Mirror Dynamic Mask,” Sensors and Actuators A: Physical, Vol. 121, No. 1, pp. 113–120, 2005.

Guo, X. W. and Liu, Y., “Improving the Imaging Quality of MOEs in DMD-based Maskless Lithography,” Microelectronic Engineering, Vol. 87, No. 5, pp. 1100–1103, 2010.

Chan, K. F., Feng, Z., Yang, R., Ishikawa, A., and Mei, W., “High-Resolution Maskless Lithography,” Journal of Micro/Nanolithography, MEMS, and MOEMS, Vol. 2, No. 4, pp. 331–339, 2003.

Hur, J. G., “Maskless Fabrication of Three-Dimensional Microstructures with High Isotropic Resolution: Practical and Theoretical Considerations,” Applied Optics, Vol. 50, No. 16, pp. 2383–2390, 2011.

Seo, M. and Kim, H., “Lithography upon Micromirrors,” Computer-Aided Design, Vol. 39, No. 3, pp. 202–217, 2007.

Ansari, M. A., Kim, K. Y., Anwar, K., and Kim, S. M., “A Novel Passive Micromixer based on Unbalanced Splits and Collisions of Fluid Streams,” Journal of Micromechanics and Microengineering, Vol. 20, No. 5, Paper No. 055007, 2010.

Liu, H. and Bhushan, B., “Nanotribological Characterization of Digital Micromirror Devices using an Atomic Force Microscope,” Ultramicroscopy, Vol. 100, No. 3, pp. 391–412, 2004.

Mekaru, H., Koizumi, O., Ueno, A., and Takahashi, M., “Inclination of Mold Pattern’S Sidewalls by Combined Technique with Photolithography at Defocus-Positions and Electroforming,” Microsystem Technologies, Vol. 16, No. 8–9, pp. 1323–1330, 2010.

Liu, R. H., Stremler, M. A., Sharp, K. V., Olsen, M. G., Santiago, J. G., and et al., “Passive Mixing in a Three-Dimensional Serpentine Microchannel,” Journal of Microelectromechanical Systems, Vol. 9, No. 2, pp. 190–197, 2000.

Kandlikar, S. G., “Exploring Roughness Effect on Laminar Internal Flow-Are We Ready for Change?,” Nanoscale and Microscale Thermophysical Engineering, Vol. 12, No. 1, pp. 61–82, 2008.

Almeida, A., Geraldes, V., and Semiao, V., “Microflow Hydrodynamics in Slits: Effects of the Walls Relative Roughness and Spacer Inter-Filaments Distance,” Chemical Engineering Science, Vol. 65, No. 11, pp. 3660–3670, 2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cho, YK., Han, TH., Ha, SJ. et al. Fabrication of passive micromixer using a digital micromirror device-based maskless lithography system. Int. J. Precis. Eng. Manuf. 15, 1417–1422 (2014). https://doi.org/10.1007/s12541-014-0485-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-014-0485-8