Abstract

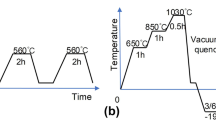

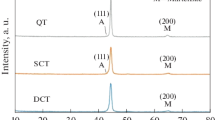

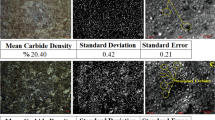

Microstructure of an alloy has a significant effect on mechanical properties. Deep cryogenic treatment extends life of tool steels because of microstructure changes. In this research, effects of microstructural parameters were studied on tensile toughness of a medium carbon-low alloy tool steel. The results showed that the maximum population density of sub-micron sized secondary carbide was obtained after 36 h of soaking time. Also, amount of secondary carbides increased with soaking or tempering times from 2.18 vol% to 12.87 vol%. In addition, high population density and high content of secondary carbides were responsible for tensile toughness enhancement. Therefore, the best results (12–35% improvement in tensile toughness) were obtained for a specimen, which underwent a full treatment cycle consisting of heating, water quenching, soaking at −196°C for 36 or 48 h and tempering at 200°C for 1 or 2 h, respectively.

Similar content being viewed by others

Abbreviations

- DCT:

-

Deep Cryogenic Treatment

- PC:

-

Primary Carbide

- PD:

-

Population Density

- SC:

-

Secondary Carbide

- SEM:

-

Scanning Electron Microscope

References

Das, D., Dutta, A., and Ray, K., “On the Refinement of Carbide Precipitates by Cryotreatment in AISI D2 Steel,” Philosophical Magazine, Vol. 89, No. 1, pp. 55–76, 2009.

Chi, H. X., Ma, D. S., Yong, Q. L., Wu, L. Z., Zhang, Z. P., and Wang, Y. W., “Effect of Cryogenic Treatment on Properties of Cr8-Type Cold Work Die Steel,” Journal of Iron and Steel Research, International, Vol. 17, No. 6, pp. 43–59, 2010.

Koneshlou, M., Meshinchi Asl, K., and Khomamizadeh, F., “Effect of Cryogenic Treatment on Microstructure, Mechanical and Wear Behaviors of AISI H13 Hot Work Tool Steel,” Cryogenics, Vol. 51, No. 1, pp. 55–61, 2011.

Li, S., Deng, L., and Wu, X., “The Mechanism Investigation of Deep Cryogenic Treatment on High Alloy Martensitic Steel by Low Frequency Internal Friction,” Cryogenics, Vol. 50, No. 8, pp. 433–438, 2010.

Bensely, A., Senthilkumar, D., Mohan Lal, D., Nagarajan, G., and Rajadurai, A., “Effect of Cryogenic Treatment on Tensile Behavior of Case Carburized Steel-815M17,” Materials Characterization, Vol. 58, No. 5, pp. 485–491, 2007.

Baldissera, P. and Delprete, C., “Effects of Deep Cryogenic Treatment on Static Mechanical Properties of 18NiCrMo5 Carburized Steel,” Materials and Design, Vol. 30, No. 5, pp. 1435–1440, 2009.

Leskovsek, V., Kalin, M., Vizintin, J., “Influence of Deep-cryogenic Treatment on Wear Resistance of Vacuum Heat-treated HSS,” Vacuum, No. 80, pp. 507–518, 2006.

Darwin, J., Mohan Lal, D., and Nagarajan, G., “Optimization of Cryogenic Treatment to Maximize the Wear Resistance of 18% Cr Martensitic Stainless Steel by Taguchi Method,” Journal of Materials Processing Technology, Vol. 195, No. 1, pp. 241–247, 2008.

Oppenkowski, A., Weber, S., and Theisen, W., “Evaluation of Factors Influencing Deep Cryogenic Treatment that Affect the Properties of Tool Steels,” Journal of Materials Processing Technology, Vol. 210, No. 14, pp. 1949–1955, 2010.

Akhbarizadeh, A., Golozar, M., Shafeie, A., and Kholghy, M., “Effects of Austenizing Time on Wear Behavior of D6 Tool Steel after Deep Cryogenic Treatment,” Journal of Iron and Steel Research, International, Vol. 16, No. 6, pp. 29–32, 2009.

ISO No. 6892-1:2009, “Metallic Materials — Tensile Testing — Part 1: Method of Test at Room Temperature,” 2009.

Dieter, G. E., “Mechanical Behavior Under Tensile and Compressive Loads,” ASM Handbook, Vol. 8, Mechanical Testing and Evaluation, pp. 99–108, 2000.

Cho, J. U., Kinloch, A., Blackman, B., Rodriguez, S., Cho, C. D., and Lee, S. K., “Fracture Behaviour of Adhesively-Bonded Composite Materials under Impact Loading,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 1, pp. 89–95, 2010.

Das, D., Dutta, A., and Ray, K., “Influence of Varied Cryotreatment on the Wear Behavior of AISI D2 Steel,” Wear, Vol. 266, No. 1, pp. 297–309, 2009.

Das, D. and Ray, K., “On the Mechanism of Wear Resistance Enhancement of Tool Steels by Deep Cryogenic Treatment,” Philosophical Magazine Letters, Vol. 92, No. 6, pp. 295–303, 2012.

Das, D., Dutta, A. K., and Ray, K. K., “Sub-Zero Treatments of AISI D2 Steel: Part I. Microstructure and Hardness,” Materials Science and Engineering: A, Vol. 527, No. 9, pp. 2182–2193, 2010.

Das, D. and Ray, K. K., “Structure-Property Correlation of Sub-Zero Treated AISI D2 Steel,” Materials Science and Engineering: A, Vol. 541, No. pp. 45–60, 2012.

Das, D., Sarkar, R., Dutta, A. K., and Ray, K. K., “Influence of Sub-Zero Treatments on Fracture Toughness of AISI D2 Steel,” Materials Science and Engineering: A, Vol. 528, No. 2, pp. 589–603, 2010.

Zhirafar, S., Rezaeian, A., and Pugh, M., “Effect of Cryogenic Treatment on the Mechanical Properties of 4340 Steel,” Journal of Materials Processing Technology, Vol. 186, No. 1, pp. 298–303, 2007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vahdat, S.E., Nategh, S. & Mirdamadi, S. Effect of microstructure parameters on tensile toughness of tool steel after deep cryogenic treatment. Int. J. Precis. Eng. Manuf. 15, 497–502 (2014). https://doi.org/10.1007/s12541-014-0363-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-014-0363-4