Abstract

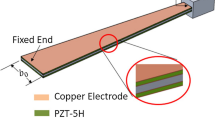

This paper proposes a new scheme for piezoelectric energy harvesting maximization. The proposed enhancement relies on a new topology of splitting a specified dimension piezo composite bender into beams with smaller width and, therefore, higher quality factor (or Q factor). The increase of Q factor allows a much more effective energy conversion process. It is shown that the proposed method, based on single splitting, increases the harvested power by a factor of up to √6, and up to √7.62 for two even-splitting compared to with no splitting. The wideband operation is accomplished by using different resonating benders in such a way that individual benders are each tuned to a different resonance frequency. Taking the configuration of single even-splitting as an example, the power output of the prototype was 39 μW at 27.2 Hz with 8 Hz bandwidth under 2 mm peak-to-peak input displacement and 3 Hz variation in resonant frequency. This corresponds to more than 2 times of power output with no splitting as well as about 23% increase in bandwidth. Such power output is sufficient to power up electronics devices such as a “2 AA dry cells-powered” digital clock with the wider range operating frequency.

Similar content being viewed by others

References

Tien, C. M. T. and Goo, N. S., “Use of a Piezocomposite Generating Element in Energy Harvesting,” Journal of Intelligent Material Systems and Structures, Vol. 21, No. 14, pp. 1427–1436, 2010.

Karami, M., Bilgen, O., Inman, D. J., and Friswell, M. I., “Experimental and Analytical Parametric Study of Single-crystal Unimorph Beams for Vibration Energy Harvesting,” Ultrasonics, Ferroelectrics and Frequency Control, IEEE Transactions on, Vol. 58, No. 7, pp. 1508–1520, 2011.

Knight, R., Mo, C., and Clark, W., “MEMS Interdigitated Electrode Pattern Optimization for a Unimorph Piezoelectric Beam,” Journal of Electroceramics, Vol. 26, No. 1–4, pp. 14–22, 2011.

Baker, J., Roundy, S., and Wright, P., “Alternative Geometries for Increasing Power Density in Vibration Energy Scavenging for Wireless Sensor Networks,” Proc. of Alternative Geometries for Increasing Power Density in Vibration Energy Scavenging for Wireless Sensor Networks, pp. 959–970, 2005.

Kim, H., Kim, J.-H., and Kim, J., “A Review of Piezoelectric Energy Harvesting Based on Vibration,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 6, pp. 1129–1141, 2011.

Kauffman, J. L. and Lesieutre, G. A., “A Low-order Model for the Design of Piezoelectric Energy Harvesting Devices,” Journal of Intelligent Material Systems and Structures, Vol. 20, No. 5, pp. 495–504, 2009.

Roundy, S. and Wright, P. K., “A Piezoelectric Vibration Based Generator for Wireless Electronics,” Smart Materials and Structures, Vol. 13, No. 5, pp. 1131–1142, 2004.

Ottman, G. K., Hofmann, H. F., Bhatt, A. C., and Lesieutre, G. A., “Adaptive Piezoelectric Energy Harvesting Circuit for Wireless Remote Power Supply,” Power Electronics, IEEE Transactions on, Vol. 17, No. 5, pp. 669–676, 2002.

Lefeuvre, E., Badel, A., Richard, C., Petit, L., and Guyomar, D., “A Comparison between Several Vibration-powered Piezoelectric Generators for Standalone Systems,” Sensors and Actuators A: Physical, Vol. 126, No. 2, pp. 405–416, 2006.

Yun, S., Kim, J., and Lee, K. S., “Evaluation of Cellulose Electroactive Paper Made by Tape Casting and Zone Stretching Methods,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 6, pp. 987–990, 2010.

Kim, J., Lee, H., and Kim, H., “Beam Vibration Control Using Cellulose-based Electro-active Paper Sensor,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 6, pp. 823–827, 2010.

Ayers, J. P., Greve, D. W., and Oppenheim, I. J., “Energy Scavenging for Sensor Applications Using Structural Strains,” Proc. of Energy Scavenging for Sensor Applications Using Structural Strains, Vol. 5057, pp. 364–375, 2003.

Kim, M., Hoegen, M., Dugundji, J., and Wardle, B. L., “Modeling and Experimental Verification of Proof Mass Effects on Vibration Energy Harvester Performance,” Smart Materials and Structures, Vol. 19, No. 4, pp. 45023–45043, 2010.

Dayou, J. and Chow, M. S., “Performance Study of Piezoelectric Energy Harvesting to Flash a LED,” International Journal of Renewable Energy Research, Vol. 1, No. 4, pp. 323–332, 2011.

Dayou, J., Chow, M. S., and Liew, W. H. Y., “Harvesting Electrical Charge from Ambient Vibration Using Piezoelectric Materials,” Borneo Science, Vol. 29, No. 3, pp. 23–31, 2011.

Chow, M. S. and Dayou, J., “Optimization of Piezoelectric Energy Harvesting System Using Split-width Method,” Proc. of 3rd CUTSE International Conference, pp. 154–157, 2011.

Sobocinski, M., Leinonen, M., Juuti, J., and Jantunen, H., “Monomorph Piezoelectric Wideband Energy Harvester Integrated into LTCC,” Journal of the European Ceramic Society, Vol. 31, No. 5, pp. 789–794, 2011.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sang, C.M., Dayou, J. & Liew, W.Y.H. Increasing the output from piezoelectric energy harvester using width-split method with verification. Int. J. Precis. Eng. Manuf. 14, 2149–2155 (2013). https://doi.org/10.1007/s12541-013-0291-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-013-0291-8