Abstract

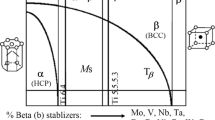

In this research, machinability of the heat treated α/β (Ti64 and Ti54M) and metastable β (Ti10.2.3) titanium alloys is investigated experimentally. Forces and temperature i.e. life of the cutting tool mainly influenced by variation in cutting speed and feed rate, therefore, the depth of cut was maintained constant while cutting speed and feed were varied. Heat treatment was found to have influence on the machinability of the analyzed alloys. The annealed and solution treated plus over aged samples of the Ti10.2.3 alloy, showed comparatively higher cutting tool temperature and higher cutting forces. This work confirmed the poorer machinability of the Ti10.2.3 alloy than the Ti64 and Ti54M alloys in different heat treatment conditions and this is due to the presence of higher content of β stabilizer elements (V and Fe). It is concluded that the proper heat treatment planning results in better machining performance of the titanium alloys.

Similar content being viewed by others

Abbreviations

- α:

-

alpha

- β:

-

beta

- STOA:

-

solution treated plus over aged

- HRC:

-

rockwellC hardness

- K c :

-

specific cutting force

- K k :

-

specific feed force

- µ:

-

friction coefficient

- FCh,c :

-

chip forming cutting force

- FCh,f :

-

chip forming feed force

- r ɛ :

-

corner radius

- r β :

-

cutting edge roundness

- γ 0 :

-

rake angle

- κ r :

-

cutting edge angle

- λ s :

-

cutting edge inclination angle

- V c :

-

cutting speed

- f :

-

feed rate

- a p :

-

depth of cut

References

Rahman Rashid, R. A., Sun, S., Wang, W., and Dargusch, M. S., “An investigation of cutting forces and cutting temperatures during laser-assisted machining of the Ti-6Cr-5Mo-5V-4Al beta titanium alloy,” Int. J. Mach Tools Manuf., Vol. 63, No. 11, pp. 58–69, 2012.

Komanduri, R. and Hou, Z, “On the thermoplastic shear instability in the machining of a titanium alloy (Ti-6Al-4V),” Metall. and Mater. Transac., Vol. 33A, pp. 2995–3010, 2002.

Arrazola, P. J., Garay, A., Iriarte, L. M., Armendia, M., Marya, S., and Maitre, F., “Machinability of titanium alloys (Ti6Al4V and Ti555.3),” Int. J. Mater. Proc. Technol., Vol. 209, pp. 2223–2230, 2009.

Armendia, M., Garay, A., Villar, A., Davies, M. A., and Arrazola, P. J., “High bandwith temperature measurement in interrupted cutting of difficult to machine materials,” CIRP Annals-Manuf. Technol., Vol. 59, No.1, pp. 97–100, 2010.

Khanna, N., Garay, A., Iriarte, L. M., Daniel, S., Sangwan, K. S., and Arrazola, P. J., “Effect of heat treatment conditions on the machinability of Ti64 and Ti54M alloys,” Procedia CIRP, Vol. 1, pp. 477–482, 2012.

Khanna, N. and Sangwan, K. S., “Machinability study of α/β and β titanium alloys in different heat treatment conditions,” Proc. IMechE. Part B — J. Engng. Manufact., Vol. 227, No. 3, pp. 357–361, 2013.

Khanna, N. and Sangwan, K. S., “Comparative machinability study on Ti54M titanium alloy in different heat treatment conditions,” Proc. IMechE. Part B — J. Engng.Manufact., Vol. 227, No. 1, pp. 96–101, 2013.

Machai, C. and Biermann, D., “Machining of a Hollow Shaft Made of β- Titanium Ti-10V-2Fe-3Al,” IEEE International Symposium on Assembly and Manufacturing, pp. 1–6, 2011.

Boyer, R. R. and Briggs, R. D., “The Use of β Titanium Alloys in the Aerospace Industry,” Journal of Materials Engineering and Performance, Vol. 14, pp. 681–685, 2005.

Ramanujam, R., Muthukrishnan, N., and Raju, R., “Optimization of cutting parameters for turning Al-SiC(10p) MMC using ANOVA and grey relational analysis,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 4, pp. 651–656, 2011.

Mandal, N., Doloi, B., and Mondal, B., “Force prediction model of Zirconia Toughened Alumina (ZTA) inserts in hard turning of AISI 4340 steel using response surface methodology,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 9, pp. 1589–1599, 2012.

Wyen, C. F. and Wegener, K., “Influence of cutting edge radius on cutting forces in machining titanium,” CIRP Annals-Manuf. Technol., Vol. 59, pp. 93–96, 2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khanna, N., Sangwan, K.S. Machinability analysis of heat treated Ti64, Ti54M and Ti10.2.3 titanium alloys. Int. J. Precis. Eng. Manuf. 14, 719–724 (2013). https://doi.org/10.1007/s12541-013-0096-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-013-0096-9