Abstract

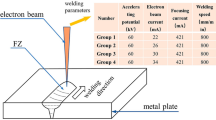

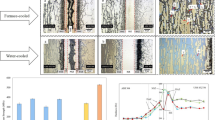

CoCrNi medium entropy alloy (MEA) recently gained a lot of attention from the scientific community due to its excellent mechanical properties at cryogenic temperatures. AISI 304 stainless steel is also a commonly used material in cryogenic environments. Therefore, the main objective of this research was to join CoCrNi MEA with AISI 304 stainless steel to obtain combinatorial properties for cryogenic applications. Vacuum diffusion welding process was utilized under different processing parameters. Three levels of welding temperatures and bonding time were selected and the influence of these parameters were investigated using microstructural characterization. Electron microprobe analysis, electron backscattered diffraction, and SEM with EDX analysis were used in the analysis of bond interface regions. At low welding temperature and time, weld discontinuities were formed which were drastically suppressed when both the parameters increased. Formation of IMCs was also found along with the bond interface and was significantly reduced upon increasing welding temperature and bonding time. Moreover, at higher parametric values thick bond interface was formed and it was concluded that its development was mainly due to the diffusion of Fe atoms. The quality of the bond interface was determined through shear testing and its fractography was also executed to correlate the processing parameters with the joint’s shear strength. Diffusivities and activation energies of the constituent elements were also calculated.

Graphical Abstract

Similar content being viewed by others

References

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375–377, 213–218 (2004)

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, S.-Y. Chang, Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6(5), 299–303 (2004)

J.-P. Liu, J.-X. Chen, T.-W. Liu, C. Li, Y. Chen, L.-H. Dai, Superior strength-ductility CoCrNi medium-entropy alloy wire. Scripta Mater. 181, 19–24 (2020)

J.-W. Yeh, Alloy design strategies and future trends in high-entropy alloys. JOM 65(12), 1759–1771 (2013)

F.D.C. Garcia Filho, R.O. Ritchie, M.A. Meyers, S.N. Monteiro, Cantor-derived medium-entropy alloys: bridging the gap between traditional metallic and high-entropy alloys. J. Mater. Res. Technol. 17, 1868–1895 (2022)

B. Gludovatz, A. Hohenwarter, K.V.S. Thurston, H. Bei, Z. Wu, E.P. George, R.O. Ritchie, Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 7(1), 10602 (2016)

D. Xu, M. Wang, T. Li, X. Wei, Y. Lu, A critical review of the mechanical properties of CoCrNi-based medium-entropy alloys. Microstructures 2, 2022001 (2022)

Z. Wu, H. Bei, F. Otto, G.M. Pharr, E.P. George, Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys. Intermetallics 46, 131–140 (2014)

C. Stephan-Scherb, W. Schulz, M. Schneider, S. Karafiludis, G. Laplanche, High-temperature oxidation in dry and humid atmospheres of the equiatomic CrMnFeCoNi and CrCoNi high- and medium-entropy alloys. Oxid. Met. 95(1), 105–133 (2021)

N.K. Adomako, J.H. Kim, Y.T. Hyun, High-temperature oxidation behaviour of low-entropy alloy to medium- and high-entropy alloys. J. Therm. Anal. Calorim. 133(1), 13–26 (2018)

C. Lu, T.-N. Yang, K. Jin, G. Velisa, P. Xiu, Q. Peng, F. Gao, Y. Zhang, H. Bei, W.J. Weber, L. Wang, Irradiation effects of medium-entropy alloy NiCoCr with and without pre-indentation. J. Nucl. Mater. 524, 60–66 (2019)

I. Moravcik, N.S. Peighambardoust, A. Motallebzadeh, L. Moravcikova-Gouvea, C. Liu, J.M. Prabhakar, I. Dlouhy, Z. Li, Interstitial nitrogen enhances corrosion resistance of an equiatomic CoCrNi medium-entropy alloy in sulfuric acid solution. Mater. Charact. 172, 110869 (2021)

M. Samiuddin, J. Li, A.D. Chandio, M. Muzamil, S.U. Siddiqui, J. Xiong, Diffusion welding of CoCrNi medium entropy alloy (MEA) and SUS 304 stainless steel at different bonding temperatures. Weld. World 65(11), 2193–2206 (2021)

S. Li, X. Sun, Y. Du, Y. Peng, Y. Chen, Z. Li, J. Xiong, J. Li, Microstructure and mechanical properties of diffusion-bonded CoCrNi-based medium-entropy alloy to DD5 single-crystal superalloy joint. Crystals 11(9), 1127 (2021)

S. Li, Y. Peng, Y. Du, L. Yuan, J. Xiong, J. Li, Microstructural characteristics and mechanical properties of IC10 superalloy and (CoCrNi)94Al3Ti3 MEA joint brazed using NiCrSiB filler. Mater. Charact. 189, 111964 (2022)

Y. Du, Z. Li, J. Xiong, Y. Chen, S. Li, J. Li, J. Dong, Diffusion bonding of FGH 98 and CoCrNi-based medium-entropy alloy: microstructure evolution and mechanical tests. Crystals 11(10), 1158 (2021)

M. Samiuddin, J. Li, Sun X. Xiong, J, Diffusion welding of CoCrNi medium-entropy alloy (MEA) and SUS 304 stainless steel using different interlayers. Metall. Res. Technol. 119(3), 312 (2022)

M. Naeem, H. Zhou, H. He, S. Harjo, T. Kawasaki, S. Lan, Z. Wu, Y. Zhu, X.-L. Wang, Martensitic transformation in CrCoNi medium-entropy alloy at cryogenic temperature. Appl. Phys. Lett. 119(13), 131901 (2021)

X.-Z. Wang, Y. Wang, Z. Huang, Q. Zhou, H. Wang, Tribocorrosion behavior of CoCrNi medium entropy alloy in simulated seawater. Metals 12(3), 401 (2022)

M. Samiuddin, L. Jinglong, M.A. Siddiqui, X. Jiangtao, R. Ling, Electrochemical corrosion behavior of CoCrNi medium entropy alloy and SUS-304 stainless steel diffusion welded joints at various bonding temperatures. Phys. Met. Metall. 122(14), 1561–1571 (2022)

S. Kundu, G. Thirunavukarasu, Structure and properties correlation of diffusion bonded joint of duplex stainless steel and Ti–6Al–4V with and without Ni–17Cr–9Fe alloy interlayer. Weld. World 60(4), 793–811 (2016)

J. Wang, Y. Li, Y. Yin, Interface characteristics in diffusion bonding of Fe3Al with Cr18-Ni8 stainless steel. J. Colloid Interface Sci. 285(1), 201–205 (2005)

P. Li, S. Wang, Y. Xia, X. Hao, H. Dong, Diffusion bonding of AlCoCrFeNi2.1 eutectic high entropy alloy to TiAl alloy. J. Mater. Sci. Technol. 45, 59–69 (2020)

P. Li, C. Li, H. Dong, B. Wu, Y. Ma, C. Zou, Y. Yang, Vacuum diffusion bonding of TC4 titanium alloy to 316 L stainless steel with AlCoCrCuNi2 high-entropy alloy interlayer. J. Alloys Compd. 909, 164698 (2022)

K.Y. Tsai, M.H. Tsai, J.W. Yeh, Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 61(13), 4887–4897 (2013)

D.L. Beke, G. Erdélyi, On the diffusion in high-entropy alloys. Mater. Lett. 164, 111–113 (2016)

D.E. Clark, R.E. Mizia, Diffusion Welding of Alloys for Molten Salt Service—Status Report (Idaho National Laboratory, Idaho Falls, 2012)

L. Chai, S.A. Tassou, A review of printed circuit heat exchangers for helium and supercritical CO2 Brayton cycles. Therm. Sci. Eng. Progress 18, 100543 (2020)

Sai K. Mylavarapu, Design, fabrication, performance testing, and modeling of diffusion bonded compact heat exchangers in a high-temperature helium test facility, Dissertation, The Ohio State University (2011)

J. Nestell, T.-L. Sham, ASME Code Considerations for the Compact Heat Exchanger (Oak Ridge National Laboratory, Oak Ridge, 2015)

S.R. Aakre, I.W. Jentz, M.H. Anderson, Nuclear code case development of printed-circuit heat exchangers with thermal and mechanical performance testing, in The 6th International Supercritical CO2 Power Cycles Symposium. Pittsburgh, Pennsylvania, USA (2018).

P. Li, H. Sun, S. Wang, X. Hao, H. Dong, Rotary friction welding of AlCoCrFeNi2.1 eutectic high entropy alloy. J. Alloys Compd. 814, 152322 (2020)

H. Nam, S. Park, E.-J. Chun, H. Kim, Y. Na, N. Kang, Laser dissimilar weldability of cast and rolled CoCrFeMnNi high-entropy alloys for cryogenic applications. Sci. Technol. Weld. Join. 25(2), 127–134 (2019)

J. Guo, C. Tang, G. Rothwell, L. Li, Y.C. Wang, Q. Yang, X. Ren, Welding of high entropy alloys—a review. Entropy (Basel) 21(4), 431 (2019)

Z.G. Zhu, Y.F. Sun, M.H. Goh, F.L. Ng, Q.B. Nguyen, H. Fujii, S.M.L. Nai, J. Wei, C.H. Shek, Friction stir welding of a CoCrFeNiAl0.3 high entropy alloy. Mater. Lett. 205, 142–144 (2017)

N. Kashaev, V. Ventzke, N. Stepanov, D. Shaysultanov, V. Sanin, S. Zherebtsov, Laser beam welding of a CoCrFeNiMn-type high entropy alloy produced by self-propagating high-temperature synthesis. Intermetallics 96, 63–71 (2018)

Y.J. Du, J.T. Xiong, F. Jin, S.W. Li, L. Yuan, D. Feng, J.M. Shi, J.L. Li, Microstructure evolution and mechanical properties of diffusion bonding Al5(TiZrHfNb)95 refractory high entropy alloy to Ti2AlNb alloy. Mater. Sci. Eng. A 802, 140610 (2021)

C. Lin, R.-K. Shiue, S.-K. Wu, J.-Y. Huang, Y.-C. Huang, Brazing of CoCrFeNi and CoCrFeMnNi equiatomic alloys using 70Au-8Pd-22Ni filler foil. Gold Bull. 53(2), 101–109 (2020)

P. Li, H. Sun, S. Wang, Y. Xia, H. Dong, G. Wen, H. Zhang, Diffusion bonding of AlCoCrFeNi2.1 eutectic high entropy alloy to GH4169 superalloy. Mater. Sci. Eng. A 793, 139843 (2020)

G. Thirunavukarasu, S. Kundu, B. Mishra, S. Chatterjee, Effect of bonding temperature on interfacial reaction and mechanical properties of diffusion-bonded joint between Ti–6Al–4V and 304 stainless steel using nickel as an intermediate material. Metall. Mater. Trans. A 45(4), 2067–2077 (2013)

M. Zajusz, M. Jawańska, J. Dąbrowa, K. Berent, M. Danielewski, Interdiffusion and diffusion paths in two-phase γ+β|γ+β diffusion couples. Comparison of experimental investigation with theoretical predictions. J. Alloys Compd. 836, 155513 (2020)

S.K. Kailasam, M.E. Glicksman, A simplified method for calculating the diffusivity matrix in ternary alloys. Acta Mater. 47(3), 905–913 (1999)

J. Wang, Y.J. Li, Y.S. Yin, Microstructure of a vacum diffusion layer in the joint of Fe–Al alloy with low-carbon steel. Mater. Sci. 41(5), 647–652 (2005)

F. Silva, J. Santos, R. Gouveia, Dissolution of grain boundary carbides by the effect of solution annealing heat treatment and aging treatment on heat-resistant cast steel HK30. Metals 7(7), 251 (2017)

A. Bjarbo, M. Hattestrand, Complex carbide growth, dissolution, and coarsening in a modified 12 pct chromium steel—an experimental and theoretical study. Metall. Mater. Trans. A 32(1), 19-27 (2001)

S.-X. Li, Y.-N. He, S.-R. Yu, P.-Y. Zhang, Evaluation of the effect of grain size on chromium carbide precipitation and intergranular corrosion of 316L stainless steel. Corros. Sci. 66, 211–216 (2013)

C.J. Thambiliyagodage, S. Ulrich, P.T. Araujo, M.G. Bakker, Catalytic graphitization in nanocast carbon monoliths by iron, cobalt and nickel nanoparticles. Carbon 134, 452–463 (2018)

H.J. Goldschmidt, Interstitial Alloy (Springer, New York, 1967), pp. 88–213

Y.J. Fang, X.S. Jiang, D.F. Mo, T.F. Song, Z.P. Luo, Microstructure and mechanical properties of the vacuum diffusion bonding joints of 4J29 kovar alloy and 316L stainless steel using pure cobalt interlayer. Vacuum 168, 108847 (2019)

Y.Y. Zhang, W.J. Yao, W. Sun, J.Y. Wang, X.J. Han, N. Wang, Rapid growth and magnetic properties of Fe7CO3 intermetallic compound. Appl. Mech. Mater. 152–154, 501–506 (2012)

H. Ding, C. Cui, W. Yang, J. Sun, The effect of Tb doping on the magnetic properties and microstructure of a TbNdFeCoB/Fe7Co3 nanocomposite permanent magnet. Mater. Res. Express 7(1), 016112 (2020)

X. Liu, B. Chen, S. Wu, P. Lin, Y. Ma, S. Tang, Y. Huang, W. Liu, Formation of nano-phase Co3Fe7 intermetallic and its strengthening in Au80Sn20/CrMnFeCoNi solder interface. J. Alloys Compd. 843, 155924 (2020)

Z.K. Li, H.M. Fu, P.F. Sha, Z.W. Zhu, A.M. Wang, H. Li, H.W. Zhang, H.F. Zhang, Z.Q. Hu, Atomic interaction mechanism for designing the interface of W/Zr-based bulk metallic glass composites. Sci. Rep. 5(1), 8967 (2015)

R. Bakhtiari, A. Yarmou Shamsabadi, K. Alipour Moradi, Shear strength/microstructure relationship for dissimilar IN738/IN718 TLP joints. Weld. World 64(1), 219–231 (2019)

M. Pouranvari, S.M. Mousavizadeh, Use of Larson–Miller parameter for modeling the progress of isothermal solidification during transient-liquid-phase bonding of IN718 superalloy. Mater. Tehnol. 49(2), 247–251 (2015)

M. Tamura, F. Abe, K. Shiba, H. Sakasegawa, H. Tanigawa, Larson–Miller constant of heat-resistant steel. Metall. Mater. Trans. A 44(6), 2645–2661 (2013)

K. Maruyama, F. Abe, H. Sato, J. Shimojo, N. Sekido, K. Yoshimi, On the physical basis of a Larson–Miller constant of 20. Int. J. Press. Vessels Pip. 159, 93–100 (2018)

X.W. Zhu, H.H. Cheng, M.H. Shen, J.P. Pan, Determination of C parameter of Larson–Miller equation for 15CrMo steel. Adv. Mater. Res. 791–793, 374–377 (2013)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Samiuddin, M., Li, J., Muzamil, M. et al. Mechanical and Microstructural Characterization of the Bond Interface Formed in Diffusion Welding of CoCrNi Medium Entropy Alloy (MEA) and AISI 304 Stainless Steel Under Various Processing Parameters. Met. Mater. Int. 29, 1421–1440 (2023). https://doi.org/10.1007/s12540-022-01309-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01309-2