Abstract

The present study investigated the effect of heat-treatment on the Stainless Steel 316L (SS316L) hybrid sample fabricated by using Directed Energy Deposition (DED) and Powder Bed Fusion (PBF) Additive Manufacturing (AM) process. The relationship between the microstructure and mechanical properties of the additively manufactured hybrid sample is studied. Further, the additively manufactured SS316L hybrid sample is subjected to different heat treatment conditions namely, stress relief, solution annealing and hot isostatic pressing and the changes happening in the mechanical and metallurgical characteristics of the hybrid sample is studied post heat treatment. From the investigation it is found that the DED process can be effectively used for depositing SS316L structure over the PBF built SS316L substrate. In addition, the mechanical characteristics of the additively manufactured SS316L hybrid sample can be effectively modified through heat treatment. As built SS316L hybrid sample has microhardness of 230.5 HV, ultimate tensile strength of 733 MPa, the yield strength value of 512 MPa. The solution treatment (HT2) of hybrid sample improves the ductility and leads to highest total elongation of 70.1%.

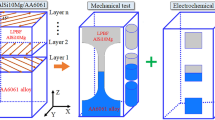

Graphical abstract

Similar content being viewed by others

Abbreviations

- AM:

-

Additive manufacturing

- PBF:

-

Powder bed fusion

- SS316L:

-

Stainless steel 316L

- DED:

-

Directed energy deposition

- DMD:

-

Direct metal deposition

- SLM:

-

Selective laser melting

- DMLS:

-

Direct metal laser sintering

- EBSD:

-

Electron back scattered diagram

- FESEM:

-

Field emission scanning electron microscope

- XRD:

-

X-ray powder diffraction

- HAZ:

-

Heat affected zone

- ABS:

-

As-built sample

- HT:

-

Heat treatment

- UTS:

-

Ultimate tensile strength

- TE:

-

Total elongation

- YS:

-

Yield strength

References

S. Shukla, V. Bajpai, Effect of cryogenic quenching on microstructure and microhardness of Ti-6Al-4V alloy. Mater. Lett. 267, 127532 (2020). https://doi.org/10.1016/j.matlet.2020.127532

Z. Zhou, S. Wang, J. Li, Y. Li, X. Wub, Y. Zhu, Hardening after annealing in nanostructured 316L stainless steel. Nano Mater. Sci. 2, 80–82 (2020). https://doi.org/10.1016/j.nanoms.2019.12.003

X. Lou, M.A. Othon, R.B. Rebak, Corrosion fatigue crack growth of laser additively-manufactured 316L stainless steel in high temperature water. Corros. Sci. 127, 120–130 (2017). https://doi.org/10.1016/j.corsci.2017.08.023

D. Svetlizky, B. Zheng, A. Vyatskikh, M. Das, S. Bose, A. Bandyopadhyay, J.M. Schoenung, E.J. Lavernia, N. Eliaz, Laser-based directed energy deposition (DED-LB) of advanced materials. Mater. Sci. Eng. A 840, 142967 (2022). https://doi.org/10.1016/j.msea.2022.142967

Y. Yang, Y. Gong, Qu. Shuoshuo, Y. Rong, Y. Sun, M. Cai, Densification, surface morphology, microstructure and mechanical properties of 316L fabricated by hybrid manufacturing. Int. J. Adv. Manuf Technol. 97, 2687–2696 (2018). https://doi.org/10.1007/s00170-018-2144-1

C. Man, Z. Duan, Z. Cui, C. Dong, D. Kong, T. Liu, S. Chen, X. Wang, The effect of sub-grain structure on intergranular corrosion of 316L stainless steel fabricated via selective laser melting. Mater. Lett. 243, 157–160 (2019). https://doi.org/10.1016/j.matlet.2019.02.047

Y. Zhou, L. Duan, F. Li, K. Chen, S. Wen, Effect of heat treatment on the microstructure and mechanical property of W/316L multi-material fabricated by selective laser melting. J. Alloys Compd. 890, 161841 (2021). https://doi.org/10.1016/j.jallcom.2021.161841

Qi. Chao, S. Thomas, N. Birbilis, P. Cizek, P.D. Hodgson, D. Fabijanic, The effect of post-processing heat treatment on the microstructure, residual stress and mechanical properties of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 821, 141611 (2021). https://doi.org/10.1016/j.msea.2021.141611

K. Benarji, Y. Ravi Kumar, A.N. Jinoop, C.P. Paul, K.S. Bindra, Efect of heat-treatment on the microstructure, mechanical properties and corrosion behaviour of SS 316 structures built by laser directed energy deposition based additive manufacturing. Met. Mater. Intern. 27, 488–499 (2021). https://doi.org/10.1007/s12540-020-00838-y

E. Tascioglu, Y. Karabulut, Y. Kaynak, Influence of heat treatment temperature on the microstructural, mechanical, and wear behavior of 316L stainless steel fabricated by laser powder bed additive manufacturing. Int. J. Adv. Manuf. Tech. 107, 1947–1956 (2020). https://doi.org/10.1007/s00170-020-04972-0

B. Onuike, A. Bandyopadhyay, Additive manufacturing in repair: Influence of processing parameters on properties of Inconel 718. Mater. Lett. 252, 256–259 (2019). https://doi.org/10.1016/j.matlet.2019.05.114

F. Haftlang, H.S. Kim, A perspective on precipitation-hardening high-entropy alloys fabricated by additive manufacturing. Mater. Des. 211, 110161 (2021). https://doi.org/10.1016/j.matdes.2021.110161

S.I. Shakil, N.R. Smith, S.P. Yoder, B.E. Ross, D.J. Alvarado, A. Hadadzadeh, M. Haghshenas, Post fabrication thermomechanical processing of additive manufactured metals: a review. J. Manuf. Proc. 73, 757–790 (2022). https://doi.org/10.1016/j.jmapro.2021.11.047

M. Kumaran, V. Senthilkumar, Experimental characterization of stainless steel 316L alloy fabricated with combined powder bed fusion and directed energy deposition. Weld. World 65, 1373–1388 (2021). https://doi.org/10.1007/s40194-021-01117-z

Z. Tong, X. Ren, J. Jiao, W. Zhou, Y. Ren, Y. Ye, E.A. Larson, Gu. Jiayang, Laser additive manufacturing of FeCrCoMnNi high-entropy alloy: effect of heat treatment on microstructure, residual stress and mechanical property. J. Alloys Compd. 785, 1144–1159 (2019). https://doi.org/10.1016/j.jallcom.2019.01.213

ChangJun Chen, K. Yan, L. Qin, M. Zhang, X. Wang, T. Zou, Hu. Zengrong, Effect of heat treatment on microstructure and mechanical properties of laser additively manufactured AISI H13 tool steel. J. Mater. Eng. Perform 26, 5577–5589 (2017). https://doi.org/10.1007/s11665-017-2992-0

X. Chen, Xu. Jia Li, H.W. Cheng, Z. Huang, Effect of heat treatment on microstructure, mechanical and corrosion properties of austenitic stainless steel 316L using arc additive manufacturing. Mater. Sci. Eng. A 715, 307–314 (2018). https://doi.org/10.1016/j.msea.2017.10.002

A. Yadollahi, N. Shamsaei, S.M. Thompson, D.W. Seely, Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater. Sci. Eng. A 644, 171–183 (2015). https://doi.org/10.1016/j.msea.2015.07.056

Oh. Wook Jin, W.J. Lee, M.S. Kim, J.B. Jeon, D.S. Shim, Repairing additive-manufactured 316L stainless steel using direct energy deposition. Opt. Laser Techol. 117, 6–17 (2019). https://doi.org/10.1016/j.optlastec.2019.04.012

D. Kong, C. Dong, X. Ni, L. Zhang, J. Yao, C. Man, X. Cheng, K. Xiao, X. Li, Mechanical properties and corrosion behavior of selective lasermelted 316L stainless steel after different heat treatment processes. J. Mater. Sci. Technol. 35, 1499–1507 (2019). https://doi.org/10.1016/j.jmst.2019.03.003

T. Ronneberg, C.M. Davies, P.A. Hooper, Revealing relationships between porosity, microstructure and mechanical properties of laser powder bed fusion 316L stainless steel through heat treatment. Mater. Des. 189, 108481 (2020). https://doi.org/10.1016/j.matdes.2020.108481

M. Godec, S. Malej, D. Feizpour, C. Donik, M. Balazic, D. Klobcar, L. Pambaguian, M. Conradi, A. Kocijan, Hybrid additive manufacturing of Inconel 718 for future space applications. Mater. Charact. 172, 110842 (2021). https://doi.org/10.1016/j.matchar.2020.110842

E. Brandl, D. Greitemeier, Microstructure of additive layer manufactured Ti–6Al–4V after exceptional post heat treatments. Mater. Lett. 81, 84–87 (2012). https://doi.org/10.1016/j.matlet.2012.04.116

X. Lou, M. Song, P.W. Emigh, M.A. Othon, P.L. Andresen, On the stress corrosion crack growth behaviour in high temperature water of 316L stainless steel made by laser powder bed fusion additive manufacturing. Corr. Sci. 128, 140–153 (2017). https://doi.org/10.1016/j.corsci.2017.09.017

F.C. Pinto, L.S. Aota, I.R. Souza Filho, D. Raabe, H.R.Z. Sandim, Recrystallization in non-conventional microstructures of 316L stainless steel produced via laser powder-bed fusion: effect of particle coarsening kinetics. J. Mater. Sci. (2022). https://doi.org/10.1007/s10853-021-06859-1

M. Laleh, A.E. Hughes, Xu. Wei, P. Cizek, M.Y. Tan, Unanticipated drastic decline in pitting corrosion resistance of additively manufactured 316L stainless steel after high-temperature post-processing. Corros. Sci. 165, 108412 (2020). https://doi.org/10.1016/j.corsci.2019.108412

B. Vrancken, L. Thijs, J.-P. Kruth, J. Van Humbeeck, Heat treatment of Ti6Al4V produced by selective laser melting: microstructure and mechanical properties. J. Alloys Compd. 541, 177–185 (2012). https://doi.org/10.1016/j.jallcom.2012.07.022

B. Barkia, P. Aubry, P. Haghi-Ashtiani, T. Auger, L. Gosmain, F. Schuster, H. Maskrot, On the origin of the high tensile strength and ductility of additively manufactured 316L stainless steel: multiscale investigation. J. Mater. Sci. Technol. 41, 209–218 (2020). https://doi.org/10.1016/j.jmst.2019.09.017

B. Blinna, F. Krebsa, M. Leyb, R. Teutschb, T. Becka, Determination of the influence of a stress-relief heat treatment and additively manufactured surface on the fatigue behavior of selectively laser melted AISI 316L by using efficient short-time procedures. Int. J. Fatigue 131, 105301 (2020). https://doi.org/10.1016/j.ijfatigue.2019.105301

J.R.O. Leo, S. Pirfo Barroso, M.E. Fitzpatrick, M. Wang, Z. Zhou, Microstructure, tensile and creep properties of an austenitic ODS 316L steel. Mater. Sci. Eng. A 749, 158–165 (2019). https://doi.org/10.1016/j.msea.2019.02.014

Acknowledgements

This work was supported by the Central Manufacturing Technology Institute (CMTI), Department of Additive Manufacturing, Government of India. The authors thank Mr. A.R.Vinod, Scientist-C, and Mr. B.N. Manjunath, Scientist-B of AM lab, CMTI for their help during sample preparation.

Funding

The article titled “Influence of heat treatment on stainless steel 316L alloy manufactured by hybrid additive manufacturing using powder bed fusion and directed energy deposition” is our original work and this has not been sent anywhere for its publication. The article may be published in your esteemed journal after its review. No funding agencies/organizations are involved in this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumaran, M., Senthilkumar, V. Influence of Heat Treatment on Stainless Steel 316L Alloy Manufactured by Hybrid Additive Manufacturing Using Powder Bed Fusion and Directed Energy Deposition. Met. Mater. Int. 29, 467–484 (2023). https://doi.org/10.1007/s12540-022-01225-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01225-5