Abstract

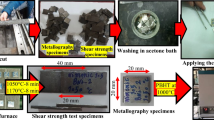

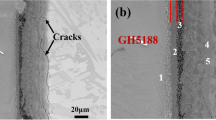

A novel fourth-generation nickel-based single crystal superalloy was bonded by vacuum brazing at 1230 °C, 1260 °C and 1290 °C for 60 min using a new type of Co-based filler alloy. The effects of the brazing temperature on the microstructure and mechanical properties of the brazed joint were investigated. The brazed joint was mainly composed of the non-isothermal solidification zone (M3B2 type-boride, CrB boride, Ni3B boride and MC carbide), isothermal solidification zone (γ and γ' Phase) and base metal. With the increase of brazing temperature, the volume fraction of borides and γ' phase in the center of the joint decreased and increased, respectively. The high-temperature tensile test results show that the tensile strength of the joints was improved with increasing brazing temperature, and the maximum tensile strength of the joint was 766 MPa after brazing at 1290 °C for 60 min. Fracture observation shows that the fracture modes of the joints were the same, which belongs to the typical quasi cleavage fracture. The element distribution in the joint was homogenized to a certain extent at 1290 °C. The segregation of Si and Ru was found, but they were still dissolved in the γ solid solution. The experimental results help to better understand the microstructure characteristics of the novel fourth-generation nickel-based single crystal superalloy and provide guidance for further optimizing the process parameters of the brazed joint.

Graphical abstract

Similar content being viewed by others

References

Z. Tan, X. Wang, Y. Du, Y. Li, Y. Yang, J. Liu, J. Liu, J. Li, Y. Zhou, X. Sun, The microstructural stability and creep performance of a novel low-cost single crystal superalloy. Met. Mater. Int. (2021). https://doi.org/10.1007/s12540-021-01040-4

R.C. Reed, T. Tao, N. Warnken, Alloys-by-design: application to nickel-based single crystal superalloys. Acta Mater 57, 5898–5913 (2009)

Y. Du, Z. Tan, Y. Yang, X. Wang, Y. Zhou, J. Li, X. Sun, Creep properties of a Nickel-based single crystal superalloy with low density. Met. Mater. Int. 27, 5173–5178 (2021)

H.J. Yan, S.G. Tian, G.Q. Zhao, N. Tian, S.K. Zhang, L.R. Liu, Deformation features and affecting factors of a Re/Ru-containing single crystal nickel-based superalloy during creep at elevated temperature. Mater. Sci. Eng. A 768, 138437 (2019)

G.E. Fuchs, Solution heat treatment response of a third generation single crystal Ni-base superalloy. Mater. Sci. Eng. A 300, 52–60 (2001)

A.C. Yeh, A. Sato, T. Kobayashi, H. Harada, On the creep and phase stability of advanced Ni-base single crystal superalloys. Mater. Sci. Eng. A 490, 445–451 (2008)

A. Heckl, S. Neumeier, M. Goken, R.F. Singer, The effect of Re and Ru on γ/γ’ microstructure, γ-solid solution strengthening and creep strength in nickel-base superalloys. Mater. Sci. Eng. A 528, 3435–3444 (2011)

Z.G. Jiang, W. Tao, K. Yu, G.W. Tan, Y.B. Chen, L.Q. Li, Z.J. Li, Comparative study on fiber laser welding of GH3535 superalloy in continuous and pulsed waves. Mater. Des. 110, 728–739 (2016)

Y.H. Ding, G.Q. You, H.Y. Wen, P.Q. Li, X. Tong, Y.H. Zhou, Microstructure and mechanical properties of inertia friction welded joints between alloy steel 42CrMo and cast Ni-based superalloy K418. J. Alloys Compd. 803, 176–184 (2019)

M. Pouranvari, A. Ekrami, A.H. Kokabi, Microstructure evolution mechanism during post-bond heat treatment of transient liquid phase bonded wrought IN718 superalloy: an approach to fabricate boride-free joints. J. Alloys Compd. 723, 84–91 (2017)

A.E. Pilehrood, H. Omidvar, A. Shamsipur, M. Khakian-Ghomi, Effect of transient liquid phase bonding followed by homogenization on the microstructure and hot tensile behavior of Inconel 738 superalloy. J. Manuf. Process. 48, 110–118 (2019)

W. Li, T. Jin, X.F. Sun, Y. Guo, H.R. Guan, Z.Q. Hu, Study of Ni–Cr–Co–W–Mo–B interlayer alloy and its bonding behaviour for a Ni-base single crystal superalloy. Scr. Mater. 48, 1283–1288 (2003)

K. Tokoro, N.P. Wikstrom, O.A. Ojo, M.C. Chaturvedi, Variation in diffusion-induced solidification rate of liquated Ni–Cr–B insert during TLP bonding of Waspaloy superalloy. Mater. Sci. Eng. A 477, 311–318 (2008)

J.D. Liu, T. Jin, N.R. Zhao, Z.H. Wang, X.F. Sun, H.R. Guan, Z.Q. Hu, Effect of transient liquid phase (TLP) bonding on the ductility of a Ni-base single crystal superalloy in a stress rupture test. Mater. Charact. 59, 68–73 (2008)

S.W. Li, J.L. Li, J.M. Shi, Y. Peng, X. Peng, X. Sun, F. Jin, J.G. Xiong, F.S. Zhang, Microstructure and mechanical properties of transient liquid phase bonding DD5 single-crystal superalloy to CrCoNi-based medium-entropy alloy. J. Mater. Sci. Technol. 96, 140–150 (2022)

A. Ekrami, S. Moeinifar, A.H. Kokabi, Effect of transient liquid phase diffusion bonding on microstructure and properties of a nickel base superalloy Rene 80. Mater. Sci. Eng. A 456, 93–98 (2007)

A. Ghasemi, M. Pouranvari, Thermal processing strategies enabling boride dissolution and gamma prime precipitation in dissimilar nickel-based superalloys transient liquid phase bond. Mater. Des. 182, 108008 (2019)

S. Neumeier, M. Dinkel, F. Pyczak, M. Goken, Nanoindentation and XRD investigations of single crystalline Ni-Ge brazed nickel-base superalloys PWA 1483 and Rene´N5. Mater. Sci. Eng. A 528, 815–822 (2011)

B.Q. Zhang, G.G. Sheng, Y.J. Jiao, Z.H. Gao, X.F. Gong, H. Fan, J. Zhong, Precipitation and evolution of boride in diffusion affected zone of TLP joint of Mar-M247 superalloy. J. Alloys Compd. 695, 3202–3210 (2017)

G.L. Wang, Y. Sun, X.G. Wang, J.D. Liu, J.G. Li, J.J. Yu, Y.Z. Zhou, T. Jin, X.D. Sun, X.F. Sun, Microstructure evolution and mechanical behavior of Ni-based single crystal superalloy joint brazed with mixed powder at elevated temperature. J. Mater. Sci. Technol. 33, 1219–1226 (2017)

N.C. Sheng, J.D. Liu, T. Jin, X.F. Sun, Z.Q. Hu, Precipitation behaviors in the diffusion affected zone of TLP bonded single crystal superalloy joint. J. Mater. Sci. Technol. 31, 129–134 (2015)

M.W. Wei, S.Y. Chen, M. Sun, J. Liang, C.S. Liu, M. Wang, Atomization simulation and preparation of 24CrNiMoY alloy steel powder using VIGA technology at high gas pressure. Powder Technol. 367, 724–739 (2020)

O.A. Idowu, N.L. Richards, M.C. Chaturvedi, Effect of bonding temperature on isothermal solidification rate during transient liquid phase bonding of Inconel 738LC superalloy. Mater. Sci. Eng. A 397, 98–112 (2005)

J.D. Liu, T. Jin, N.R. Zhao, Z.H. Wang, X.F. Sun, H.R. Guan, Z.Q. Hu, Microstructural study of transient liquid phase bonded DD98 and K465 superalloys at high temperature. Mater. Charact. 62, 545–553 (2011)

M. Pouranvari, A. Ekrami, A.H. Kokabi, Solidification and solid state phenomena during TLP bonding of IN718 superalloy using Ni–Si–B ternary filler alloy. J. Alloys Compd. 563, 143–149 (2013)

D. Amiri, S.A. Sajjadi, R. Bakhtiari, A. Kamyabi-Gol, The role of TLP process variables in improvement of microstructure and mechanical properties in TLP joints of GTD-111/Ni–Cr–Fe–B–Si/GTD-111 system. J. Manuf. Process. 32, 644–655 (2018)

M.C. Liu, G.M. Sheng, H.J. He, Y.J. Jiao, Microstructural evolution and mechanical properties of TLP bonded joints of Mar-M247 superalloys with Ni–Cr–Co–W–Ta–B interlayer. J. Mater. Process. Technol. 246, 245–251 (2017)

R. Bakhtiari, A. Ekrami, T.I. Khan, The effect of TLP bonding temperature on microstructural and mechanical property of joints made using FSX-414 superalloy. Mater. Sci. Eng. A 546, 291–300 (2012)

J. Crank, The Mathematics of Diffusion, 2nd edn. (Oxford University Press, Oxford, 1975)

Y.M. He, F. Xiao, Y. Sun, C.Y. Lu, S.J. Chen, W.J. Chen, H.X. Li, W.J. Zheng, Y.H. Ma, Z.Y. Ding, J.G. Yang, Z.L. Gao, Tailoring microstructure and mechanical performance of Hastelloy N-Hastelloy N superalloy joint through modifying brazing processing parameters and post thermal exposure. Mater. Charact. 173, 110947 (2021)

V. Jalilvand, H. Omidvar, M.R. Rahimipour, H.R. Shakeri, Influence of bonding variables on transient liquid phase bonding behavior of nickel based superalloy IN-738LC. Mater. Des. 52, 36–46 (2013)

N.C. Sheng, B. Li, J.D. Liu, T. Jin, X.F. Sun, Z.Q. Hu, Influence of the substrate orientation on the isothermal solidification during TLP bonding single crystal superalloys. J. Mater. Sci. Technol. 30, 213–216 (2014)

M. Khakian, S. Nategh, S. Mirdamadi, Effect of bonding time on the microstructure and isothermal solidification completion during transient liquid phase bonding of dissimilar nickel-based superalloys IN738LC and Nimonic 75. J. Alloys Compd. 653, 386–394 (2015)

M. Pouranvari, A. Ekrami, A.H. Kokabi, Effect of bonding temperature on microstructure development during TLP bonding of a nickel base superalloy. J. Alloys Compd. 469, 270–275 (2009)

B. Binesh, A.J. Gharehbagh, Transient liquid phase bonding of IN738LC/MBF-15/IN738LC: solidification behavior and mechanical properties. J. Mater. Process. Technol. 32, 1137–1151 (2016)

X. Tan, J. Liu, T. Jin, Z. Hu, H. Hong, B. Choi, I. Kim, C. Jo, Effect of ruthenium on tensile properties of a single crystal Ni-based superalloy. Met. Mater. Int. 18, 769–775 (2012)

K.L. Cao, W.C. Yang, J.C. Zhang, C. Liu, P.F. Qu, H.J. Su, J. Zhang, L. Liu, Solidification characteristics and as-cast microstructures of a Ru-containing nickel-based single crystal superalloy. J. Mater. Res. Technol. 11, 474–486 (2021)

Acknowledgements

The financial support from the National Natural Science Foundation of China (Grant Numbers 51871221); the National Key R&D Program of China (Grant Number 2017YFA0700704); and the National Science and Technology Major Project (Grant Numbers 2017-VI-0002-0072, J2019-VI-0023-0139 and J2019-VII-0004-0144) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Z.P., Liu, J.D., Qiu, K.Q. et al. Effects of Brazing Temperature on Microstructure and High-Temperature Strength of Joints Using a Novel Fourth-Generation Nickel-Based Single Crystal Superalloy. Met. Mater. Int. 29, 444–456 (2023). https://doi.org/10.1007/s12540-022-01223-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01223-7