Abstract

In this study after designing and manufacturing HPT’s anvils, copper disks with more than 99.99% purity were processed by HPT at two selected pressures for various turns. The results showed that the softening of Cu processed disks occurs very quickly. Also, the softening range expanded from near the edge to near the center of processed disks, and this range was more expanded by increasing turns and pressure. The uniformity of hardness along the radius of the processed disk was obtained at a pressure of 1.25 GPa for 2 turns. Microhardness-equivalent strain plots showed a maximum pick at the strain of 2–3 and then it reached a steady-state at the equivalent strain of 5–6. Mean crystallite size and dislocation density were calculated using the Rietveld refinement method from XRD patterns. The results illustrated mean crystallite size and dislocation density due to recrystallization and recovery decreased by increasing pressure and turn. These results could help long-time applications of copper processed by SPD processes that are unusable due to long-time softening.

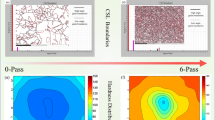

Graphic abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zehetbauer, Y.T. Zhu, JOM 58, 33 (2006)

M. Vaseghi, H.S. Kim, Mater. Design 36, 735 (2012)

M. Vaseghi, H.S. Kim, A. Karimi Taheri, A. Momeni, J. Mater. Eng. Perform. 22, 1666 (2013)

M. Vaseghi, A.K. Taheri, J.H. Yoo, S.H. Joo, H.S. Kim, Mater. Sci. Forum 654-656, 1014 (2010)

R.Z. Valiev, T.G. Langdon, Prog. Mater. Sci. 51, 881 (2006)

A.P. Zhilyaev, T.G. Langdon, Prog. Mater. Sci. 53, 893 (2008)

M.I. Latypov, I.V. Alexandrov, Y.E. Beygelzimer, S. Lee, H.S. Kim, Comput. Mater. Sci. 60, 194 (2012)

Y. Saito, H. Utsunomiya, N. Tsuji, T. Sakai, Acta Mater. 47, 579 (1999)

P.W. Bridgman, Phys. Rev. 48, 825 (1935)

Y. Ito, Z. Horita, Mater. Sci. Eng. A 503, 32 (2009)

K. Edalati, T. Fujioka, Z. Horita, Mater. Sci. Eng. A 497, 168 (2008)

K. Edalati, Y. Ito, K. Suehiro, Z. Horita, Int. J. Mater. Res. 100, 1668 (2009)

K. Edalati, Z. Horita, Mater. Trans. 51, 1051 (2010)

K. Edalati, Y. Hashiguchi, H. Iwaoka, H. Matsunaga, R.Z. Valiev, Z. Horita, Mater. Sci. Eng. A 729, 340 (2018)

B. Oberdorfer, B. Lorenzoni, K. Unger, W. Sprengel, M. Zehetbauer, R. Pippan, R. Würschum, Scripta Mater. 63, 452 (2010)

D.J. Lee, E.Y. Yoon, D.-H. Ahn, B.H. Park, H.W. Park, L.J. Park, Y. Estrin, H.S. Kim, Acta Mater. 76, 281 (2014)

H.W. Zhang, K. Lu, R. Pippan, X. Huang, N. Hansen, Scripta Mater. 65, 481 (2011)

Z. Horita, K. Kishikawa, K. Kimura, K. Tatsumi, T.G. Langdon, Mater. Sci. Forum 558-559, 1273 (2007)

H. Jiang, Y.T. Zhu, D.P. Butt, I.V. Alexandrov, T.C. Lowe, Mater. Sci. Eng. A 290, 128 (2000)

A.I. Almazrouee, K.J. Al-Fadhalah, S.N. Alhajeri, Y. Huang, T.G. Langdon, Adv. Eng. Mater. 21, 1801300 (2019)

M. Umemoto, B.D. Long, Y. Todaka, K. Tsuchiya, Mater. Sci. Forum 654, 1205 (2010)

Y. Huang, S. Sabbaghianrad, A.I. Almazrouee, K.J. Al-Fadhalah, S.N. Alhajeri, T.G. Langdon, Mater. Sci. Eng. A 656, 55 (2016)

J. Gubicza, S.V. Dobatkin, E. Khosravi, A.A. Kuznetsov, J.L. Lábár, Mater. Sci. Eng. A 528, 1828 (2011)

E.N. Popova, V.V. Popov, E.P. Romanov, V.P. Pilyugin, Phys. Met. Metall. 103, 407 (2007)

V.V. Popov, E.N. Popova, D.D. Kuznetsov, A.V. Stolbovskii, V.P. Pilyugin, Phys. Met. Metall. 115, 682 (2014)

H.M. Rietveld, J. Appl. Crystallogr. 2, 65 (1969)

L.B. Mccusker, R.B. Von Dreele, D.E. Cox, D. Louër, P. Scardi, J. Appl. Crystallogr. 32, 36 (1999)

M. Karolus, E. Łagiewka, J. Alloy. Compd. 367, 235 (2004)

G.K. Williamson, R.E. Smallman, Philos. Mag. A 1, 34 (1956)

N. Hansen, B. Ralph, Acta Metall. 30, 411 (1982)

R.Z. Valiev, Y.V. Ivanisenko, E.F. Rauch, B. Baudelet, Acta Mater. 44, 4705 (1996)

D. Setman, E. Schafler, E. Korznikova, M.J. Zehetbauer, Mater. Sci. Eng. A 493, 116 (2008)

J.Y. Huang, Y.T. Zhu, H. Jiang, T.C. Lowe, Acta Mater. 49, 1497 (2001)

K. Edalati, R. Miresmaeili, Z. Horita, H. Kanayama, R. Pippan, Mater. Sci. Eng. A 528, 7301 (2011)

D.J. Lee, E.Y. Yoon, L.J. Park, H.S. Kim, Scripta Mater. 67, 384 (2012)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hosseini Kahnooj, S.A., Vaseghi, M. & Sameezadeh, M. Softening and Microstructure Evolution of Pure Copper Disks Processed by High Pressure Torsion. Met. Mater. Int. 28, 2646–2651 (2022). https://doi.org/10.1007/s12540-022-01173-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01173-0