Abstract

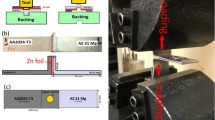

The formation of Mg17Al12 and Al3Mg2 is inevitable even in solid-state joining of Al and Mg alloys by friction stir welding (FSW). In the present study, the effect of a thin inter-layer of Sn (tin) and FSW parameters (pin length and tool rotation speed) on the microstructure and strength of friction stir lap welds of 3 mm thick AA6061 Al alloy and AZ31B Mg alloy sheets was investigated. A ~ 20 µm thick Sn layer was deposited on AZ31B alloy by displacement plating. The heat generated during the welding melted the Sn layer and the rotation action of the tool pushed the molten Sn to the hooks on the advancing side and retreating side. The extent of Mg17Al12 and Al3Mg2 intermetallic compound formation was reduced with Sn inter-layer with limited formation of Mg2Sn. The Sn inter-layer helped improve the lap shear strength at lower tool rotational speed (600 RPM) and pin lengths of 3.25 and 3.75 mm compared to joints without Sn inter-layer. Lap welds prepared with a 3.25 mm pin at 600 RPM had a lap shear strength of 245 N/mm which is the highest value reported so far and is 116% higher compared to joints without Sn inter-layer. This was due to elimination of hook at the advancing side and retreating side and disintegration of intermetallic compounds.

Graphic abstract

Similar content being viewed by others

Availability of data

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations. Data will be made available on request.

References

H. Friedrich, S. Schumannn, J. Mater. Process. Tech. 117, 276 (2001)

J.L. Murray, J. Phase Equilib. 3, 60 (1982)

L. Liu, H. Wang, G. Song, J. Ye, J. Mater. Sci. 42, 565 (2007)

Y.C. Chen, K. Nakata, Scr. Mater. 58, 433 (2008)

S. Hirano, K. Okamoto, M. Doi, O. Kamura, M. Inagaki, Y. Aono, Weld. Int. 18, 702 (2004)

D. Dietrich, D. Nickel, M. Krause, T. Lampke, M.P. Coleman, V. Randle, J. Mater. Sci. 46, 357 (2011)

A.A. McLean, G.L.F. Powell, I.H. Brown, V.M. Linton, Sci. Technol. Weld. Join. 8, 462 (2003)

L. Boccarusso, A. Astarita, P. Carlone, F. Scherillo, F. Rubino, A. Squillace, J. Manuf. Process. 44, 376 (2019)

N. Yamamoto, J. Liao, S. Watanabe, K. Nakata, Mater. Trans. 50, 2833 (2009)

H.M. Rao, W. Yuan, H. Badarinarayan, Mater. Des. 66, 235 (2015)

Z. Liu, X. Meng, S. Ji, Z. Li, L. Wang, J. Manuf. Process. 31, 552 (2018)

K.P. Mehta, P. Carlone, A. Astarita, F. Scherillo, F. Rubino, P. Vora, Mater. Sci. Eng. A 759, 252 (2019)

L. Liu, X. Liu, S. Liu, Scr. Mater. 55, 383 (2006)

A. Panteli, Y.-C. Chen, D. Strong, X. Zhang, P.B. Prangnell, JOM 64, 414 (2012)

Y. Wang, G. Luo, J. Zhang, Q. Shen, L. Zhang, Mater. Sci. Eng. A 559, 868 (2013)

H. Shakeri, M.A. Mofid, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00731-8

F. Yin, C. Liu, Y. Zhang, Y. Qin, N. Liu, Mater. Sci. Technol. 34, 1104 (2018)

F. Liu, Z. Zhang, L. Liu, Mater. Charact. 69, 84 (2012)

F. Scherm, J. Bezold, U. Glatzel, Sci. Technol. Weld. Join. 17, 364 (2012)

P. Penner, L. Liu, A. Gerlich, Y. Zhou, Sci. Technol. Weld. Join. 18, 541 (2013)

J. Shang, K. Wang, Q. Zhou, D. Zhang, J. Huang, G. Li, Mater. Des. 34, 559 (2012)

S. Niu, S. Ji, D. Yan, X. Meng, X. Xiong, J. Mater. Process. Tech. 263, 82 (2019)

S. Ji, S. Niu, J. Liu, X. Meng, J. Mater. Process. Tech. 267, 141 (2019)

R. Gan, Y. Jin, Sci. Technol. Weld. Join. 23, 164 (2018)

A. Abdollahzadeh, A. Shokuhfar, J.M. Cabrera, A.P. Zhilyaev, H. Omidvar, J. Manuf. Process. 34, 18 (2018)

B. Zheng, L. Zhao, Q. Lv, G. Wan, D. Cai, S. Dong, X. Hu, Mater. Res. Express 7, 076504 (2020)

V.K. Patel, S.D. Bhole, D.L. Chen, Sci. Technol. Weld. Join. 17, 342 (2012)

X.J. Liu, R.S. Huang, H.Y. Wang, S.H. Liu, Sci. Technol. Weld. Join. 12, 258 (2007)

X. Dai, H. Zhang, B. Wang, A. Ji, J. Liu, J. Feng, Mater. Design 98, 262 (2016)

A. Bandi, S.R. Bakshi, Metall. Mater. Trans. A 51, 6269 (2020)

A.J. Bard, L.R. Faulkner, Electrochemical Methods: Fundamentals and Applications, 2nd edn. (John Wiley & Sons, New York, 2000)

R. Crawford, G.E. Cook, A.M. Strauss, D.A. Hartman, M.A. Stremler, Sci. Technol. Weld. Join. 11, 657 (2006)

K. Kumar, S.V. Kailas, Mater. Sci. Eng. A 485, 367 (2008)

H. Schmidt, J. Hattel, J. Wert, Model. Simul. Mater. Sci. Eng. 12, 143 (2004)

V. Firouzdor, S. Kou, Metall. Mater. Trans. A 41, 3238 (2010)

G. Buffa, G. Campanile, L. Fratini, A. Prisco, Mater. Sci. Eng. A 519, 19 (2009)

L. Cederqvist, A.P. Reynolds, Weld. J. 80, 281 (2001)

J. Mohammadi, Y. Behnamian, A. Mostafaei, H. Izadi, T. Saeid, A.H. Kokabi, A.P. Gerlich, Mater. Charact. 101, 189 (2015)

S. Ji, Z. Li, L. Zhang, Z. Zhou, P. Chai, Mater. Des. 103, 160 (2016)

Funding

One of the authors (S.R. Bakshi) acknowledges funding from Institute Research and Development Award (Junior Level) of Indian Institute of Technology Madras (MET1617839RFIRSRRB) for carrying out the work.

Author information

Authors and Affiliations

Contributions

Anil Bandi: Conceptualization, Investigations, Formal analysis, Writing—Original Draft. Srinivasa. R. Bakshi: Conceptualization, Resources, Supervision, Funding acquisition, Writing—Review & Editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent to participate

Not applicable.

Consent for publication

We give the consent for publishing our work in Metals and Materials International journal.We give the consent for publishing our work in Metals and Materials International journal.

Ethics approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bandi, A., Bakshi, S.R. Friction Stir Lap Welding of AZ31B and AA6061 Alloys Using Tin as an Inter-Layer. Met. Mater. Int. 28, 1678–1696 (2022). https://doi.org/10.1007/s12540-021-01039-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01039-x