Abstract

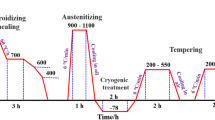

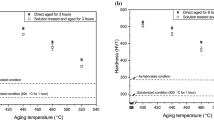

The kinetics of low-temperature tempering in a dissimilar resistance spot weldment between medium Mn transformation-induced plasticity (MT) steel and dual-phase (DP) steel were investigated to interpret the change of failure mode after a paint-baking process. After the isothermal heat treatments with various soaking conditions, the Johnson–Mehl–Avrami (JMA) model describing nucleation and growth kinetics was adopted. The results indicated that the tempering kinetics parameters were different for each area of the welds. Especially in the coarse-grained heat-affected zone (CGHAZ) in the MT steel, carbon diffusion from martensite to austenite acts as a tempering mechanism at an earlier stage of tempering. Thereafter, the tempering mechanism changes to epsilon carbide precipitation and coarsening. In comparison, the change was relatively slow or absent in the DP steel CGHAZ and fusion zone because of its lower kinetics parameters. Based on the results of this study, ways to improve the cross-tension strength of entire welds in automotive applications of MT steel are discussed.

Graphic Abstract

Similar content being viewed by others

References

Z.C. Li, H. Ding, R.D.K. Misra, Z.H. Cai, Mater. Sci. Eng. A 682, 211 (2017)

J. Hu, L.X. Du, H. Liu, G.S. Sun, H. Xie, H.L. Yi, R.D.K. Misra, Mater. Sci. Eng. A 647, 144 (2015)

Z.H. Cai, H. Ding, R.D.K. Misra, Z.Y. Ying, Acta Mater. 84, 229 (2015)

Z.Z. Zhao, J.H. Liang, A.M. Zhao, J.T. Liang, D. Tang, Y.P. Gao, J. Alloy. Compd. 691, 51 (2017)

N. Saeidi, M. Jafari, J.G. Kim, F. Ashrafizadeh, H.S. Kim, Met. Mater. Int. 26, 168 (2020)

J. Han, A.K. da Silva, D. Ponge, D. Raabe, S.-M. Lee, Y.-K. Lee, S.-I. Lee, B. Hwang, Acta Mater. 122, 199 (2017)

A. Arlazarov, M. Gouné, O. Bouaziz, A. Hazotte, G. Petitgand, P. Barges, Mater. Sci. Eng. A 542, 31 (2012)

H. Aydin, E. Essadiqi, I.-H. Jung, S. Yue, Mater. Sci. Eng. A 564, 501 (2013)

Q. Jia, L. Liu, W. Guo, Y. Peng, G. Zou, Z. Tian, Y.N. Zhou, Metals 8, 48 (2018)

N. Lun, D.C. Saha, A. Macwan, H. Pan, L. Wang, F. Goodwin, Y. Zhou, Mater. Design 131, 450 (2017)

G. Park, K. Kim, S. Uhm, C. Lee, Mater. Sci. Eng. A 752, 206 (2019)

G. Park, K. Kim, S. Uhm, C. Lee, Mater. Sci. Eng. A 766, 138401 (2019)

D.W. Fan, H.S. Kim, B.C. De Cooman, Steel Res. Int. 80, 241 (2009)

E. Pereloma, I. Timokhina, in Automotive Steels, ed. by R. Rana, S.B. Singh (Woodhead Publishing, Sawston, 2017), pp. 259–288

H. Kantereit, Bake Hardening Behavior of Advanced High Strength Steels under Manufacturing Conditions (SAE International, Warrendale, 2011)

T. Waterschoot, K. Verbeken, B.C. De Cooman, ISIJ Int. 46, 138 (2006)

H. Mirzadeh, A. Najafizadeh, Mater. Chem. Phys. 116, 119 (2009)

Q. Zhou, X. Wu, N. Shi, J. Li, N. Min, Mater. Sci. Eng. A 528, 5696 (2011)

E. Biro, J.R. McDermid, S. Vignier, Y.N. Zhou, Mater. Sci. Eng. A 615, 395 (2014)

T.K. Eller, L. Greve, M. Andres, M. Medricky, H.J.M. Geijselaers, V.T. Meinders, A.H. van den Boogaard, J. Mater. Process. Tech. 234, 309 (2016)

M. Avrami, J. Chem. Phys. 7, 1103 (1939)

A.K. De, B.C. De Cooman, S. Vandeputte, J. Mater. Eng. Perform. 10, 567 (2001)

X. Fang, Z. Fan, B. Ralph, P. Evans, R. Underhill, J. Mater. Process. Tech. 132, 215 (2003)

E. Biro, J.R. McDermid, S. Vignier, Y.N. Zhou, Mater. Sci. Eng. A 615, 395 (2014)

M. Marya, X. Gayden, Weld. J. 84, 172 (2005)

M. Pouranvari, Mater. Sci. Eng. A 546, 129 (2012)

T. Sekita, S. Kaneto, S. Hasuno, A. Sato, T. Ogawa, K. Ogura, JFE Tech. Rep. 2, 1 (2004)

A.H. Cottrell, B. Bilby, P. Phys. Soc. Lond. A 62, 49 (1949)

L. Yuan, D. Ponge, J. Wittig, P. Choi, J.A. Jiménez, D. Raabe, Acta Mater. 60, 2790 (2012)

Z.R. Hou, T. Opitz, X.C. Xiong, X.M. Zhao, H.L. Yi, Scripta Mater. 162, 492 (2019)

M. Kuzmina, D. Ponge, D. Raabe, Acta Mater. 86, 182 (2015)

L. Cheng, C. Brakman, B. Korevaar, E. Mittemeijer, Metall. Trans. A 19, 2415 (1988)

F.D. Murari, T.M.F. De Melo, B.M. Gonzalez, ISIJ Int. 50, 463 (2010)

V.B. Hernandez, S. Nayak, Y. Zhou, Metall. Mater. Trans. A 42, 3115 (2011)

I.M. Lifshitz, V.V. Slyozov, J. Phys. Chem. Solids 19, 35 (1961)

Acknowledgements

The authors would like to thank the POSCO Technical Research Laboratory for financial support of this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Park, G., Kim, K., Lee, Y. et al. Kinetics Study on Low-Temperature Tempering of Martensitic Phase in Medium Mn Steel Weldment During Paint-Baking Heat Treatment. Met. Mater. Int. 28, 1157–1168 (2022). https://doi.org/10.1007/s12540-021-00985-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-00985-w